Textured geomembrane, also known as textured or embossed geomembrana Liner, is the widely used geomembranes that feature a patterned surface with raised or textured areas. These textures create irregularities on the surface of the geomembrane, resulting in a rougher or more undulated surface compared to smooth geomembranes. The textures can vary in size, shape, and pattern, and they are typically formed during the manufacturing process of the geomembrane.

The purpose of texturing geomembranes is to enhance their interface friction and improve their stability and performance in containment applications.

1. What Are Benefits of Textured Geomembrane?

1.1 Increased Friction

The textured surface of geomembranes significantly increases friction with soil or other layers, improving overall performance. Additionally, this enhanced resistance effectively prevents slippage, particularly on steep slopes. Moreover, the added stability proves crucial in challenging terrains where movement is likely. Furthermore, the geomembranes maintain their integrity even under harsh environmental conditions. Consequently, these features ensure long-term reliability and safety in various engineering applications.

1.2 Improved Interface Shear Strength

The textured surface of geomembranes actively enhances interlocking and bonding with surrounding materials. As a result, this significantly improves the interface shear strength between adjacent layers. Moreover, this increased shear strength plays a crucial role in maintaining structural stability. Specifically, it proves vital for demanding applications such as landfill liners and protective covers. Ultimately, these properties ensure reliable performance while preventing potential failures in critical engineering projects.

1.3 Enhanced Geomembrane Stability

The textured surface of geomembranes effectively reduces movement and displacement caused by hydraulic forces. Additionally, it resists wind uplift and minimizes issues from settlement by increasing surface friction. Furthermore, the textured profile significantly enhances shear strength between the geomembrane and adjacent materials. As a result, this improvement directly boosts the overall stability of the liner system. Ultimately, these combined benefits lead to superior long-term performance in various environmental conditions.

1.4 Improved Leak Detection

The textured surface of geomembranes creates visible and tactile indicators that actively help detect leaks. Additionally, any irregularities in the surface pattern noticeably alter water flow patterns and pressure distribution. As a result, these changes make breaches or defects stand out more clearly during routine inspections. Moreover, the enhanced detectability allows maintenance teams to identify problems faster and more accurately. Consequently, this leads to quicker repairs and better long-term performance of containment systems.

1.5 Compatibility with Cover Materials

Textured geomembranes commonly work together with cover materials such as soil, aggregate, or geosynthetic clay liners (GCLs). The specially designed surface texture actively increases interface friction between these layers while simultaneously improving bonding strength. As this enhanced connection develops, it directly boosts the overall stability of the entire cover system. Furthermore, the improved interaction between materials leads to noticeably better long-term performance. Engineers consequently prefer textured geomembranes for projects requiring reliable, slip-resistant containment solutions.

2. How To Produce Quality Textured Geomembrane?

Textured geomembranes can be produced using various technologies to achieve the desired surface texture and performance characteristics. Some of the common technologies used for manufacturing textured geomembranes include:

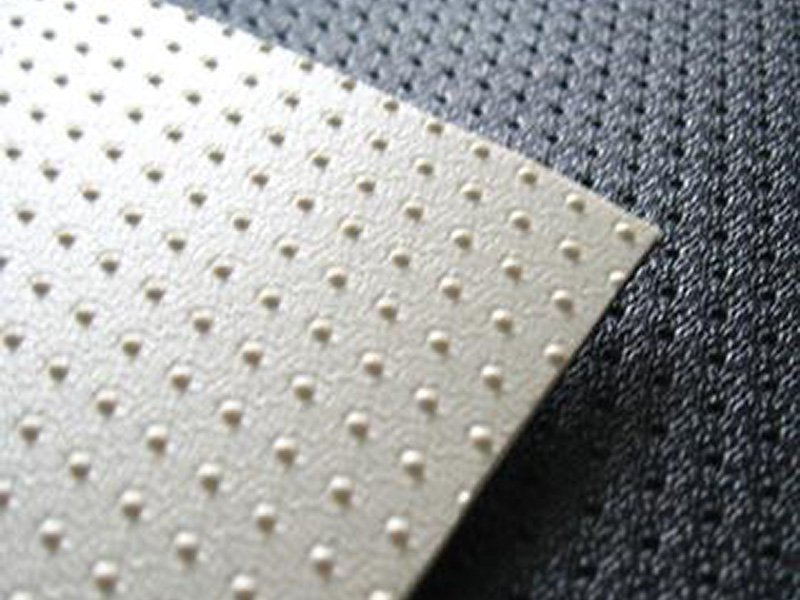

2.1 Dimpled Textured geomembrane by Calendering

Calendering involves passing geomembranes through heated rollers. Pressure and temperature combine to create textured surfaces. Patterns are embossed or imprinted onto the material during this process. This method is ideal for uniform or shallow surface textures.

The process ensures consistent and precise texturing. Heated rollers enhance the material’s durability and functionality. Calendering is widely used for its efficiency and reliability. It produces high-quality geomembranes with controlled surface features.

2.2 Extrusion Embossing

Extrusion embossing involves pushing geomembrane material through a textured flat die. The die creates the desired surface pattern as the material emerges. This method offers precise control over texture and pattern. It is ideal for producing textured geomembranes with specific performance needs.

The process ensures consistent and accurate texturing. Extrusion embossing enhances the material’s functionality and durability. It is widely used for its efficiency and versatility. This technique meets high-quality standards for geomembrane production.

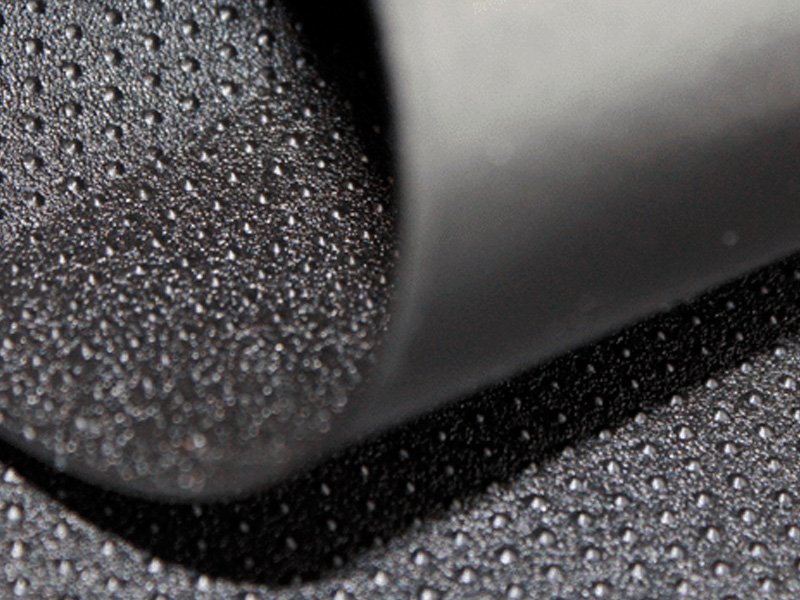

2.3 Nitrogen roughening blowing molding Textured geomembrane

Blown film equipment extrudes the polymer in a single step. This process controls both top layers simultaneously. Rough and irregular surface asperities are created by injecting nitrogen. Nitrogen is added into the molten polymer layer during extrusion. After leaving the mold, nitrogen escapes, forming the desired texture.

Auxiliaries like white pigments or carbon black can be added. These are mixed into the polymer during this step. The core layer remains unaffected by the texturing process. This method ensures precise control over surface characteristics. It enhances the geomembrane’s performance and durability effectively.

2.4 Spray Textured Geomembrane

Spray roughened geomembrane production involves a two-step process. First, molten polyethylene pellets are mixed with hot air. This mixture is then sprayed onto a smooth base geomembrane. The base geomembrane can be made using round die co-extrusion. Alternatively, flat die extrusion can also produce the base layer.

This method creates a textured surface on the geomembrane. The process ensures strong adhesion and durability. It enhances the material’s performance for specific applications. Spray roughening is efficient and versatile for geomembrane production.

3. What Is Textured Geomembrane Used For?

Textured geomembranes enhance friction, stability, and leak detection.They are used in landfill liners, secondary containment systems, reservoirs, ponds, and mining.These applications require stability, interface friction, and leak prevention.Textured geomembranes improve performance and longevity in challenging conditions.

3.1 Landfill Liners and Covers

Textured geomembranes are used as primary and secondary liners in landfills.They prevent leachate migration into soil and groundwater.The textured surface enhances frictional resistance and shear strength.This improves stability and performance of the liner system.Textured geomembranes may also be used in landfill covers.They prevent precipitation infiltration and control gas emissions.

3.2 Mining and Tailings Storage Facilities

Textured geomembranes are used in mining and tailings storage.They contain and manage process water, tailings, and by-products.The textured surface improves stability and integrity of liners.This is crucial in challenging terrain and harsh conditions.Textured geomembranes also prevent soil and groundwater contamination in heap leach pads and ore processing facilities.

3.3 Secondary Containment Systems

Textured geomembranes are used in secondary containment for hazardous materials.They store chemicals and fuel tanks safely.The textured surface improves frictional resistance and bonding.This reduces liner movement and aids leak detection.Textured geomembranes protect against environmental contamination.They ensure compliance with regulatory requirements.

3.4 Erosion Control and Slope Stabilization

Textured geomembranes are used in erosion control and slope stabilization.They protect soil from erosion, landslides, and weathering.The textured surface increases friction and stability.This prevents soil movement and promotes vegetation growth.Textured geomembranes can be installed on slopes, embankments, and shorelines.These examples show the wide range of applications for textured geomembranes.

4. How To Weld The Textured Geomembrane ?

Welding textured geomembranes requires careful attention.Proper fusion is crucial while maintaining weld integrity.A 20cm edge is needed for the welding joint.Here’s a general overview of the welding process for textured geomembranes:

4.1 Surface Preparation

Before welding, clean and dry the geomembrane surfaces.Remove contaminants, debris, and moisture.Trim irregularities or damaged areas for clean seams.

4.2 Welding Equipment Setup

Choose welding equipment and methods based on geomembrane type and project needs.Common methods: hot wedge welding, hot air welding, extrusion welding.Set up equipment following manufacturer’s specifications and parameters.

4.3 Temperature and Speed Control

Adjust welding equipment temperature and speed based on geomembrane material, thickness, and texture.Optimal settings ensure proper fusion without overheating or damage

4.4 Welding Technique

Align textured geomembrane panels with proper seam overlap according to design.Apply heated welding tool to surfaces, moving gradually along the seam.Maintain constant pressure and speed during welding.

4.5 Visual Inspection

Inspect weld seam for proper fusion and bonding during welding.Check for uniform weld bead, no voids or gaps, and consistent texture.Address any defects immediately to prevent leaks or failures.

4.6 Testing and Quality Assurance

After welding, perform quality assurance tests to verify the integrity and performance of the welded seam. This may include peel tests, destructive testing, or non-destructive testing methods to assess weld strength, integrity, and water tightness.

5. About GEOSINCERE

GEOSINCERE has been dedicated to manufacturing wholesaling Textured Geomembrane and geosynthetics products and solutions to worldwide customers since its foundation in 2007. Our main innovative, high quality products include geotextiles, geomembranes, geogrids, geocells, geosynthetic clay liners, and drainage boards, etc al.

GEOSINCERE offers both high quality geosynthetic products but also professional design and installation service. OEM, ODM, custom development and fabrication are also available. If you have any questions or inquiries, please contact us, we will reply as soon as possible.

I am extremely impressed with your writing talents as well as with the format on your weblog.

Is that this a paid subject or did you customize

it yourself? Anyway keep up the excellent high quality writing, it is rare to

peer a great weblog like this one these days. Stan Store!

Cheers! I like this!

casino en ligne

You mentioned that really well!

casino en ligne fiable

You reported it terrifically.

casino en ligne francais

Truly a good deal of useful advice!

casino en ligne

Fine material Appreciate it!

casino en ligne

Fantastic facts, Regards.

casino en ligne

With thanks! I appreciate this!

casino en ligne fiable

Whoa quite a lot of helpful material!

casino en ligne

Truly a lot of beneficial advice!

meilleur casino en ligne

Nicely put. Regards!

casino en ligne

Thanks a lot. Valuable stuff.

webpage

Fine advice Cheers!

casino en ligne

Thanks. Ample facts.

casino en ligne

Very good information. With thanks!

casino en ligne

You expressed this very well.

casino en ligne

You’ve made your stand quite effectively!.

casino en ligne

Truly lots of useful knowledge.

casino en ligne

Nicely put, Thanks!

casino en ligne

Wonderful material Regards.

casino en ligne

Cheers. I appreciate it.

casino en ligne