The main geotextile functions should be properly performed to improve soil characteristics in civil engineering projects. Generally, there are 5 main geotextile we should understand in the selelction and application of geotextile.

Geotextile, also known as geotextile fabric, is a permeable geosynthetic material comprised solely of textiles. Geotextiles are the cost effective and preferred lining system widely used with foundation, soil, rock, earth, or any other geotechnical engineering-related material as an integral part of human-made project, structure, or system.

Geotextile is a special type of polymer fabric (polyester, polypropylene etc.) with very small holes that is used to improve the soil properties in civil construction projects. Different types of geotextile has different typical characteristics and performs main different functions.

1 Types of Geotextiles

Geotextie is made from polymer fibers. A variety of polymers can be used to manufacture synthetic fibers and fabrics, including polyamides (nylon-66, nylon-6, and nylon 46), polyacrylonitrile, polyvinyl alcohol, polyethylene naphthalene, polypropylene (PP), polyethylene (PE), and polyethylene terephthalate (PET), to name just a few. For geotextiles, however, PP, PE, and PET are the types of polymers used almost exclusively. Of these, PP is the dominant polymer used in the geotextile market.

Generally speaking, there three main types of geotextiles which can be categorized as non woven geotextile, woven geotextile and knitted geotextile by its manufacturing process. According to material type or synthetic yarns the geotextile used, woven geotextile can be categorized into monofilament woven geotextile, multifilament woven geotextile, woven slit-film monofilament geotextile, woven slit-film multifilament geotextile, etc. The non woven geotextile can be categorized into nonwoven continuous filament heat bonded geotextile, nonwoven continuous filament needle-punched geotextile, nonwoven staple needle-punched geotextile, nonwoven resin bonded geotextile, knitted geotextile and other woven and nonwoven combinations geotextile, etc. Geotextile is a special type of polymer fabric (polyester, polypropylene etc.) with very small holes that is used to improve the soil properties in civil construction projects. Different types of geotextile has different typical characteristics and performs main different functions.

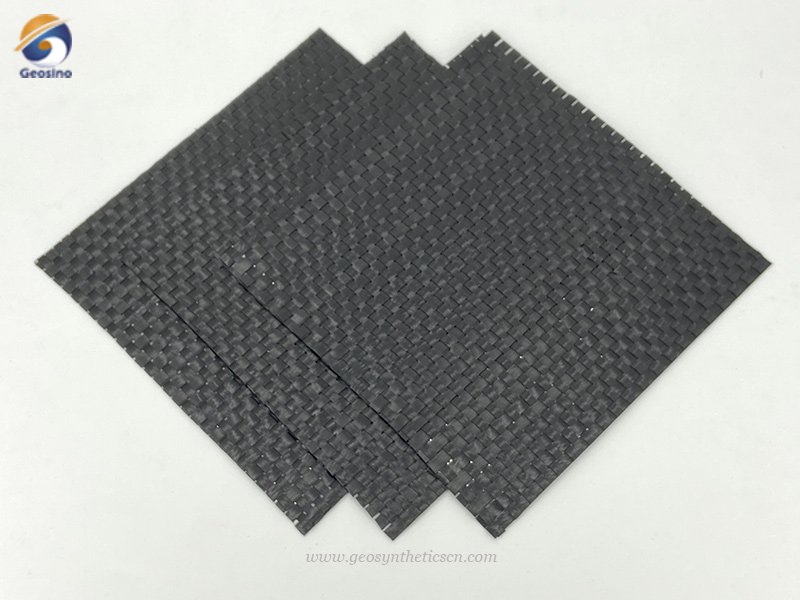

1.1 Woven Geotexile

Woven Geotextile is a planar textile structure produced by interlacing two or more sets of elements such as yarns, fibers, or filaments where the elements pass each other to form a stable structure. The Woven geotextiles perform the function of separation and increase the strength of the soil. As the yarn strength of their warp is much higher, they have more tensile strength. As a result, it can take much more load. Woven geotextile fabrics have a planar textile structure that may be either flat slit films or round monofilaments. Woven slit-film geotextiles are typically used where high strength properties are needed and filtration requirements are less critical. Woven monofilament geotextiles get priority where both strength and filtration needs. Woven geotextile is especially useful in landscaping applications and streetscaping applications as asphalt overlay or road underlayment for road construction to give added support. Woven geotextile products mainly include pet woven geotextile and PP woven geotextile.

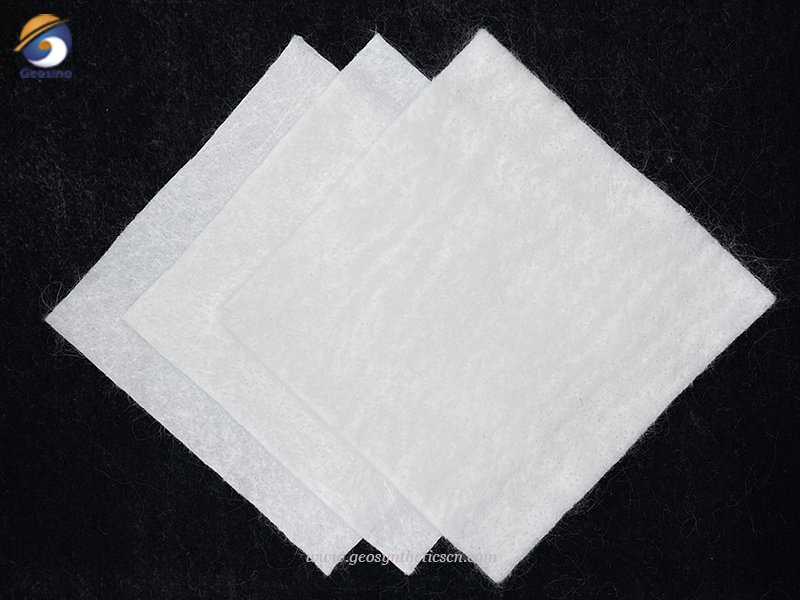

1.2 Non Woven Gextextile

Non woven geotextiles, mostly known as filter fabrics, are the planar and essentially random textile structure produced by bonding, interlocking of fibers, or both, accomplished by mechanical, chemical, thermal, or solvent means and combination thereof. Non woven geotextile has lower tensile strength, and excellent separation, drainage and filtration ability than woven geotextiles. Non woven geotextiles perform just as good as others with lower mass meaning less plastic used for better environment, the nonwoven geotextiles are typically used in aggregate drains, asphalt pavement overlays and erosion control.

GEOSINCERE non woven geotextile products mainly include staple fiber needle punched non woven geotextile and continuous filament non woven geotextile. The non woven geotextiles are widely used for filtration, separation, protection, drainage applications in civil environmental engineering and construction projects.

1.3 Knitted Geotextiles

Knitted getextiles are formed by interlocking a series of loops of one or more yarns to form a planar structure. It can combine the functions of medium, carrier and interface, used for reinforced composites for an extremely wide range of civil engineering applications. The fast development of new generation of industrial types of geotextiles, such as the knitted geotextile will make considerable contribution and new demands on the innovative ability for the civil engineering industry.

2. Brief Introduction of Soil Mechanics

From the common sense, force is the amount of pushing or pulling required to move an object. From the engineer’s view, force is the number of loads that act upon a structure. When external forces are applied to a structure, especially the basic foundation is soil , internal stresses (internal forces) develop resistance to the outside forces. There are five fundamental loads such as compression, tension, shear, bending and torsion, which generate different kinds of stress each force exerts on soil. Tension means two pulling (opposing) forces that stretch an object trying to pull it apart. Compression means two pushing (opposing) forces that squeeze an object trying to compress it. Shear means wo pushing or pulling adjacent forces, acting close together but not directly opposing each other. When a moment or “turning force” is applied to a structural member that is fixed on both ends, such as a pole beam, making it deflect or bend (bending). Torsion orTwisting is Created when a moment or “turning force” is applied to a structural member (or piece of material) making it deflect at an angle (twist).

3 Geotextile Properties

As the preferred geotechnical material, geotextile has many excellent properties to endure or overcome the external force worked on the soil, it can help to improve soil characteristics greatly. Tensile strength, elongation, impact strength, stress crack resistance, heat resistance are the important properties of the geotextile to be used for civil construction applications such as roads, harbors, reservoirs, canals, dams and many others retaining construction to improve soil stability, provide erosion control or aid in drainage. Different types of geotextiles have different properties, so you should choose appropriate type of geotextile according to the customer’s project demand/requirements.

4 Geotextile Functions

GEOSINCERE has over 15 years of experience in the geotextile research and development, manufacturing and installation services. Our extensive lines of geosynthetics products are well known for their ensured quality, high performance, excellent durability and best cost effectiveness. Geotextiles and other geosynthetics products and solutions can meet your requirements by our solid technologies, innovative engineering solutions and excellent customer services. In our opinion, the woven geotextiles and non woven geotextiles are mainly used to separate, filter, reinforce, stabilize, protect, retain and drain soil in the civil engineering projects. So the geotextile can be defined by five discrete functions described aas followed.

- (1) Separation. Geotextile is placed between different layers in the construction preventing migration and mingling of materials, yet allowing free water movement.

- (2) Filtration. Geotextile is designed to retain particles while allowing free water movement, making it possible to separate two layers during intense hydraulic activity.

- (3)Drainage. Excess water is drained off the construction by flowing in the plane of the geotextile, but not by passing through the geotextile as when used for filtration.

- (4)Protection (Cushioning). The thickness and strength of the geotextile can protect geomembrane from puncture when placing geotextile on both sides of geomembrane.

- (5)Reinforcement. Geotextile increases the soil tensile shear strength and lateral restraint through interfacial friction as the same amount steel does in concrete.

4.1 Separation Function

The main application areas of a geotextile used as a separator are in road and railway projects. The geotextile preserves the drainage and the strength characteristics of the aggregate material. The non woven geotextile, especially the short fiber needle punched geotextile, is the cost effective geotextile fabric which is suitable and widely used to perform separation functions.

- Prevent the reduction of load bearing capacity caused by the mixing of fine-grained subgrade with the aggregate base.

- Increase the bearing capacity by preventing the loss of aggregate into soft subgrade and increasing the degree of compaction.

- Reduce the deterioration of roads through frost heave effects.

- Eradicate the need to remove weak subgrade.

- Maintain the drainage capacity of the aggregate base.

- Prevent migration of fine particles especially under dynamic loads.

4.2 Filtration Function

The restraining of soil or other particles subjected to hydrodynamic forces while allowing the passage of fluids into or across a geotextile or a geotextile-related product.

- Typically, the opening size and the permeability are used to describe the geotextile’s filtration properties. (porous ability)

- The filtration function is associated with dam construction, erosion control, road drainage and subsoil drainage.

- The permeability of the least permeable layer determines the system’s permeability. Usually the soil has a permeability which is significantly lower than that of the geotextile.

- Generally thick geotextiles are susceptible to compression. When installed under pressure, the permeability is reduced.

4.3 Drainage Function

Geotextiles will efficiently collect superfluous water from structures, such as rainwater or surplus water, from the soil and discharge it. The non woven geotextile is designed and manufactured with porous structure to perform filtration functions.

- A geotextile should not be used as a (direct) drainage layer by itself.

- Drainage is the collecting and transporting of precipitations, ground waters and/or other fluids.

- Synthetic drains incorporating a geotextile filter have proved to be a more economic alternative to traditional sand drains, soakaways and other drainage systems.

- Typically geosynthetic drainage mats or drains are made of a core sandwiched between geotextile filters.

4.4 Protection Function

Geotextiles are an ideal protection from erosion of earth embankments by wave action, currents or repeated drawdown. Non woven geotextile and woven geotextile can perform protection functions. But woven geotextile can play better effects.

- Typically, geotextiles are used for protection of geosynthetic barriers in landfill, roofing, tank and water projects.

- The most important properties of a geotextile in a protection function are puncture resistance and product uniformity.

- The thickness and strength of the geotextile can protect geomembrane from puncture when placing geotextile on both sides of geomembrane.

4.5 Reinforcement Function

Due to the high soil fabric friction coefficient and high tensile strength, geotextile, especially woven geotextile, can be used to reinforce or stabilize earth structures by means of fill materials. Non woven geotextile is not the good choice for reinforcement applications.

In many applications a geotextile fulfills a stabilization or reinforcement function. In its stabilization function the geotextile provides the soil with tensile strength and thus complements the soil’s lack of tensile strength when subject to vertical loads.

High initial modulus and high elongation are important to withstand large local deformations and resist puncturing.

5 Avaid Damage During Installation

A geotextile will not perform any functions if it is destroyed during or immediately after installation. Geotextile functions can perform well when installed correctly. Analyses indicate that the critical period in the life-cycle of a geotextile is during the construction process rather than during the service life. Thus 95% of the damage usually occurs during installation.

About GEOSINCERE

As the professional geotextile and geosynthetics manufacturer and wholesaler, GEOSINCERE is always committed to geotextile research and development, manufacturing and installation services.

Our main innovative, high quality products include geotextiles, geomembranes, geogrids, geocells, geosynthetic clay Liner, and drainage boards, etc al. GEOSINCERE offers both high quality geosynthetic products but also professional design and installation service. OEM, ODM, custom development and fabrication are also available. If you have any questions or inquiries, please fill and submit the following form, we will reply as soon as possible.

Error: Contact form not found.