Geotextile, also known as geotextile fabric, is the permeable geosynthetic material comprised solely of textiles. The ASAE (Society for Engineering in Agricultural, Food, and Biological Systems) defines a geotextile as a “fabric or synthetic material placed between the soil and a pipe, gabion, or retaining wall: to enhance water movement and retard soil movement, and as a blanket to add reinforcement and separation.” A geotextile should consist of a stable network that retains its relative structure during handling, placement, and long-term service. There are mainly three types of geotextiles including non woven geotextile, woven geotextile and knitted geotextile. The geotextiles are produced varied from polyester or polypropylene polymers by different manufacturing processes that make them useful in a variety of civil construction applications. These types of geotextiles are widely used with foundation, soil, rock, earth, or any other geotechnical engineering-related material as an integral part of human-made project, structure, or system. The main functions of geotextiles are used to increase soil stability, provide erosion control or aid in drainage. Geotextile and its geosynthetics family products such as geomembrane, geogrids, geonets and others are also suitable in geotechnical and environmental construction or engineering applications. GEOSINCERE has been dedicated to geotextile and geosynthetics manufacturing and wholesaling for over 15 years. We are also providing geotextile installation service. Our customers are from over 80 countries.

What Are 3 Types of Geotextiles

What Are the Types of Geotextiles? Generally speaking, there are three main types of geotextiles which can be categorized as non woven geotextile, woven geotextile and knitted geotextile by varied textile polymers and its manufacturing process. According to the synthetic yarns the geotextile used, woven geotextile can be categorized into monofilament woven geotextile, multifilament woven geotextile, woven slit-film monofilament geotextile, woven slit-film multifilament geotextile, etc. The non woven geotextile can be categorized into nonwoven continuous filament heat bonded geotextile, nonwoven continuous filament needle-punched geotextile, nonwoven staple needle-punched geotextile, nonwoven resin bonded geotextile, knitted geotextile and other woven and nonwoven combinations geotextile, etc. Followed are main three types of geotextiles.

- Non Woven Geotextiles

- Woven Geotextiles

- Knitted Geotextiles

Non Woven Geotextiles

Non woven geotextiles, also known as nonwoven geotexitles or non-woven geotextiles, are made in two different ways: either using staple fibre, namely short fibres, interlocked together usually by the needle punched manufacturing process; or continuous filament – long, continuous strands of synthetic fibers which are laid together, bonded by mechanically entangling the fibers, and then needled punched and interlocked to improve strength. The non woven geotextile are commonly available in three colors, white, black or orange for different applications. Another manufacturing method of non woven geotextiles is spunbonding. During this process extruded filaments are spun onto a collecting belt and bonded by applying heated rolls.

Needle punched non woven geotextiles are felt-like and very flexible, having a fibrous network with distinctive pores, they are typically have high permeability as a result of high porosity and conformability because of their high elongation characteristics. Thermally spun, bonded, nonwoven fabrics typically have high modulus, compared to needle-punched nonwoven geotextile fabrics, and high conformability. Non-woven geotextiles are usually used for separation, drainage, filtration and protection applications.

Non woven geotextile will perform a filtration function that it allows liquid to pass while controlling the soil or particles migration through the geotextile. The typically used in non woven geotextile filtration examples include wrapping geotextile around a pipe or enclosing stone with a geotextile to create a system that allows water to pass, but keeps soil from infiltrating and clogging the system, aggregate drains, asphalt pavement overlays and erosion control. Nonwoven drainage geotextiles are an economical alternative to graded aggregate and sand filters and can eliminate many of the problems associated with using, purchasing and transporting aggregate. Non woven geotextile fabric can also be used in separation applications. These include pave patios or walkways. Non woven geotextile is widely used as the bottom under the HDPE geomembrane liner to protect it from puncture.

There are two types of non woven geotextiles. One is staple fiber needle punched geotextile fabric, another is continuous filament geotextile fabric. Staple fibre needle punched geotextile fabric is the most common and cost effective non woven geotexilte on the market. The short fibre nonwoven geotextile manufacturers can source staple fibre yarns and invest custom manufacturing equipment to put into production. The continuous filament geotextile fabric manufacturing process should produce the filament synthetic yarns and the filament geotextile at the continuous manufacturing processes, which means big investment and higher manufacturing technology.

Staple fibre needle punched geotextile is often manufactured from short polypropylene or polyester fibers. Polypropylene has good chemical stability and cost/weight ratio, but polyester offers good anti aging resistance, high creep strength and tensile strength. It is the most cost effective and extensively used geotextile fabric to ensure improved performance and design life of soil or granular layers in a range of civil, coastal and environmental engineering projects.

Continuous filament non woven geotextile offers optimum performance per unit weight which features high tensile strength and puncture resistance, good acid and alkali resistance, excellent drainage and anti-aging properties, etc. It is widely used for separation, filtration, drainage, protection functions in civil environmental engineering and construction projects.

GEOSINCERE offers extensive range of non woven geotextiles available in many weights, strengths and characteristics for your demands.

Woven Geotextiles

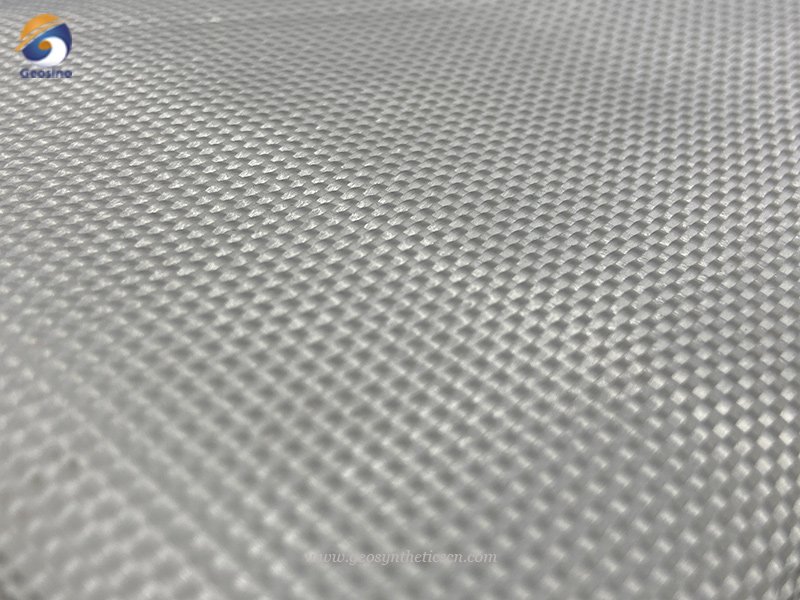

Woven Geotextile is a planar, permeable textile structure produced by interlacing two or more sets of elements such as yarns, fibers, rovings, or, filaments where the elements pass each other to form a stable structure. Woven geotextiles are used with soil, rock, earth, or any other geotechnical engineering-related material as an integral part of a human-made project, structure, or system. Woven geotextile has high tensile strength, low elongation and can offer a very high load capacity which is the ideal geotechnical material mainly perform the functions of stabilization and reinforcement to provide dimensional stability and load distribution, reducing rutting and extending the life of paved and unpaved roadways. While woven fabrics are relatively impermeable and won’t provide good drainage, their high compressive strength makes them an ideal choice for roads, parking lots, railways construction projects, etc. Woven geotextiles can also be used for filtration applications as it is still permeable. Woven geotextile is measured through trapezoidal tear strength and CBR puncture resistance. Apparent opening size refers to weave pattern of woven geotextile, which refers to how fast the woven geotextile fabric can drain. Woven geotextile is especially useful in landscaping applications and streetscaping applications as asphalt overlay or road underlayment for road construction to give added support.

Main Characteristics and Benefits of Woven Geotextiles

- High tensile strength, Good tear strength

- Good resistance to mineral acids and weak alkalis

- Strengthens and supports aggregates

- Increases performance life of the road

- Withstands tough construction loading

- Disintegrates to strong alkalis and high temperatures

- High permittivity and water flow rates

- Proven performance for most stabilization and reinforcement applications

- Extensive range of size, thickness and grades

- Ease of installation reduces time and labor costs

Polypropylene(PP) and PET are the types of polymers used almost exclusively used to manufacture woven geotextile. Of these, PP is the dominant polymer used in the geotextile market. The base material should fulfills ASTM standard requirement. GEOSINCERE manufactures high performance pp woven geotextile and PET woven geotextile for demands. Woven geotextile is relatively light in weight, high grab strength, excellent puncture resistance, good stabilization, high ultraviolet ray resistance, high elongation, excellent stability and high tensile strength to allow for soil separation, maximum slope support, stabilization and erosion control, etc. It is widely used in in such civil environmental engineering and construction projects as roads, pavements, railroads, structures and water conservancy project, etc.

Knitted Geotextiles

The large scale infrastructural projects in the Asian, European and North American markets rise a good demand of knitted geotextiles. The knitted geotextiles are mainly warp-knitted textiles made from warp-knitting machines. The kintted geotextiles are manufactured by the process of interlocking a series of loops of yarn together. The knitting process consists of interconnecting loops of yarn on powered automated machines. The machines are equipped with rows of small, hooked needles to draw formed yarn loops through previously formed loops. All of the knitted geosynthetics are formed by using the knitting technique in conjunction with some other method of geosynthetics manufacturing process, such as weaving. Depending on the manufacturing process, knitted geotextiles can offer high tensile strength and elasticity. The perfect flexibility of knitted geotextiles makes them better and more economical than any other geotextile material. The knitted geotextile fabrics and other geosynthetics help to improve construction efficiency and effectiveness.

Knitted getextiles are formed by interlocking a series of loops of one or more yarns to form a planar structure. It can combine the functions of medium, carrier and interface, used for reinforced composites for an extremely wide range of civil engineering applications.

In recent years, Getextile fabrics play more and more important role in the environmental, constructional, and civil engineering projects. Many types of geotextiles combine the functions of medium, carrier and interface for an extremely wide range of civil construction projects for soil fills to improve soil characteristics. Geotextiles make poor soil more manageable, enabling construction in places that would otherwise be unsuitable. The fast development of new generation of industrial types of geotextiles will make considerable contribution and new demands on the innovative ability for the civil engineering industry.

About GEOSINCERE

As the professional geotextile and geosynthetics manufacturer and wholesaler, GEOSINCERE is always committed to geotextile research and development, manufacturing and installation services. We can provide our customers with most extensive lines of geotextiles and geomembranes for civil, mining, environmental and aquaculture engineering applications. GEOSINCERE has been keeping on investing in technological innovation, manufacturing facilities improvement and turnkey engineering abilities. Our extensive lines of geosynthetics products are well known for their ensured quality, high performance, excellent durability and best cost effectiveness. GEOSINCERE brand geotextiles and other geosynthetics products and solutions can meet your requirements by our solid technologies, innovative engineering solutions and excellent customer services. Hope to be your partner.

Our main innovative, high quality products include geotextiles, geomembranes, geogrids, geocells, geosynthetic clay Liner, and drainage boards, etc al. GEOSINCERE customers are from more than 100 countries including America, Australia, France, Sweden, UK, Turkey, Hong Kong, Hungary, New Zealand, Poland, Mexico, Ecuador, Brazil, Pakistan, Bangladesh, Thailand, Vietnam, Malaysia, Indonesia, Singapore, Philippines, Sri Lanka, India, UAE, Saudi Arabia, Qatar, Kenya, Ghana, Ethiopia, Somalia, Nigeria, South Africa, Swaziland, Mongolia, etc.

GEOSINCERE offers both high quality geosynthetic products but also professional design and installation service. OEM, ODM, custom development and fabrication are also available. If you have any questions or inquiries, please contact.