Beneath the majestic dams, at the bottom of modern landfills, and beside the crisscrossing highways, lies a discreet yet crucial barrier: the geomembrane. Known as the “invisible guardian” of engineering, it silently safeguards our environmental safety and engineering stability with its exceptional anti-seepage performance.Waterproof Geomembrane is an extremely low permeability material made of high molecular weight polymers (such as HDPE, LDPE, PVC, etc.). Its permeability coefficient is extremely low, which can effectively prevent the passage of fluids such as water, gas, and chemicals. This makes it an ideal choice for constructing artificial anti-seepage layers, ensuring that liquids are controlled in a specific area and do not leak to the outside world.

1. The Core Function of Waterproof Geomembrane

Building a Reliable Anti-Seepage Barrier

Geomembranes are waterproof barrier materials made primarily from high-molecular-weight polymers (such as high-density polyethylene, low-density polyethylene, and polyvinyl chloride.

Their core functions can be summarized as follows:

- Environmental Protection and Pollution Control: This is the most important application of geomembranes. In landfills, hazardous waste disposal sites, tailings ponds, and other projects, geomembranes serve as the core anti-seepage layer, effectively preventing harmful leachate from seeping into the ground and protecting soil and groundwater from pollution. They are the “lifeline” of environmental projects.

- Water Conservation and Allocation: In water conservancy projects such as artificial lakes, reservoirs, rivers, and irrigation channels, laying geomembranes can significantly reduce water loss due to seepage, improve water storage efficiency, and safeguard agricultural irrigation and urban and rural water supply.

- Moisture and Seepage Control in Construction Projects: They are used to waterproof and dehumidify building basements, rooftop gardens, tunnels, subways, and other projects, ensuring dry underground spaces and extending the service life of the structures.

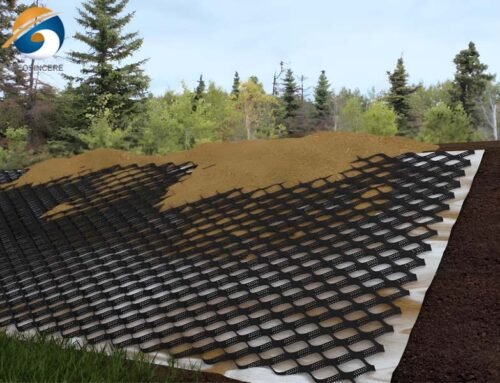

- Municipal and Transportation Engineering: In roadbeds for highways, railways, and airports, geomembranes can separate different soil layers, preventing the upwelling of soft soil in the base layer. They also provide drainage and reinforcement, improving roadbed stability.

- Aquaculture: As the lining of aquaculture ponds, geomembranes prevent water-soil exchange, facilitating water quality control, reducing disease transmission, and improving aquaculture profitability.

2. What are the characteristics of Waterproof Geomembrane?

The Cornerstone of Outstanding Performance

Waterproof Geomembranes are able to shoulder such a heavy responsibility thanks to a series of exceptional material properties:

2.1 Waterproof Geomembrane – Extremely Low Permeability

This is the most fundamental characteristic of geomembranes. With an extremely low permeability coefficient (typically less than 10^-11 cm/s), they are virtually impermeable, forming an extremely effective fluid barrier.

2.2 Waterproof Geomembrane – Excellent Chemical Resistance

HDPE geomembranes, in particular, are highly resistant to most acids, alkalis, salts, and other chemicals, and can withstand the long-term demands of complex corrosive environments such as landfill leachate and industrial wastewater.

2.3 Waterproof Geomembrane – Excellent UV Resistance:

By adding antioxidants such as carbon black to the raw materials, geomembranes effectively resist ultraviolet radiation from sunlight, slowing the aging process and ensuring a long service life even in exposed environments.

2.4 Waterproof Geomembrane – High Mechanical Strength

They possess excellent tensile strength, tear strength, and puncture resistance. They can withstand the stresses of construction during installation, the pressure of overburden material, and potential foundation settlement, making them resistant to damage.

2.5 Waterproof Geomembrane – Good Flexibility and Deformability

Geomembranes have a certain degree of elongation, allowing them to adapt to uneven settlement and deformation of the foundation. They resist breaking easily due to localized deformation, thus maintaining the integrity of the anti-seepage system.

2.6 Waterproof Geomembrane – Easy Installation and Reliable Connections

Geomembranes are shipped in large rolls, enabling efficient on-site installation. Connections are primarily made using hot-melt welding or extrusion welding, creating welds stronger than the parent material and ensuring the integrity and continuity of the anti-seepage layer.

2.7 Waterproof Geomembrane – Cost-Effectiveness

Compared to traditional clay anti-seepage layers, geomembranes are thinner, require less material, and can be installed more quickly, significantly conserving land resources, reducing project costs, and shortening construction schedules.

2.8 Waterproof Geomembrane – Durability and long life

Under reasonable design and construction conditions, the service life of high-quality HDPE geomembrane can reach more than 50 years, or even longer, providing long-term and stable protection for the project.

3. What are the Main Application Areas and Specific Functions of Waterproof Geomembrane?

Based on their core performance, geomembranes play an irreplaceable role in a variety of fields:

3.1 Environmental Engineering: Protecting the Pure Land

- Landfills: This is the most classic application of geomembranes. They serve as a liner, preventing leachate from contaminating the surrounding soil and groundwater. They also act as a cover layer, preventing rainwater from entering, reducing leachate generation, and controlling the spread of odorous gases.

- Sewage Treatment Ponds/Oxidation Ponds: They ensure that wastewater and chemical treatment agents are safely contained within the ponds, preventing leakage and secondary pollution.

- Tailings Ponds: Mining tailings wastewater often contains harmful substances such as heavy metals. Geomembrane linings are a key barrier to prevent these pollutants from polluting the environment.

3.2 Water Conservancy Projects: Securing every drop of precious water.

- Artificial Lakes, Reservoirs, and Canals: In areas with severe seepage, laying geomembranes can significantly reduce water loss and improve water storage efficiency.

- Dam and Levee: They are used as anti-seepage linings for dam bodies, enhancing their stability and preventing dangerous conditions such as pipe bursts.

3.3 Construction: Creates a dry foundation for buildings.

- Basements and tunnels: Used as a waterproofing membrane to prevent groundwater from seeping into buildings, ensuring a dry and safe underground space.

- Rooftop gardens: Laying a geomembrane beneath the green layer prevents moisture from seeping into the building structure while retaining water for plant growth.

3.4 Agriculture and Aquaculture: Boosting agricultural production

- Aquaculture ponds: Maintaining pond water levels, reducing seepage losses, and facilitating cleaning and management.

- Irrigation reservoirs/canals: Similar to water conservancy projects, ensuring that precious water resources are used efficiently for irrigation.

In short, while thin, geomembranes carry a significant weight. As a fundamental anti-seepage material in modern civil and environmental engineering, they serve as a silent guardian, building a solid line of defense in protecting water resources, preventing pollution, and ensuring project safety. From macro-level water conservancy hubs to micro-level rooftop waterproofing, geomembranes are ubiquitous and a vital technological force driving sustainable development.

4. Choosing a Good Waterproof Geomembrane Supplier

Shandong Geosino New Material Co.,Ltd (Brand:Geosincere) is the professional Waterproof Geomembrane and geosynthetics manufacturer and wholesaler located in Shandong Province, China. We are a professional manufacturer, exporter and wholesaler for such geosynthetic products as HDPE Pool Liner, geotextiles, geogrids, geocells, geosynthetic clay liners (GCLs), drainage boards, etc.

4.1 Global Reach and Proven Track Record

We have been exporting Waterproof Geomembrane and geosynthetics to over 100 countries. They choose Geosincere as a partner for more than 10 years.

4.2 Technological Investment and Product Quality

GEOSINCERE has been keeping on investing in technological innovation, manufacturing facilities improvement, and turnkey engineering abilities. We have invested 10 million dollars into our manufacturing factory which is equipped with state-of-the-art automatic production lines to manufacture high-quality geomembranes and other geosynthetics with optimized processes. Our extensive lines of geosynthetics products are well known for their ensured quality, high performance, excellent durability, and best cost effectiveness.

4.3 Customer-Centric Solutions and Competitive Advantages

GEOSINCERE brand Waterproof Geomembrane and other geosynthetics products and solutions can meet your requirements by our solid technologies, innovative engineering solutions, and excellent customer services. GEOSINCERE always tries our best to solve the most complex civil, mining, and environmental challenges with our innovative and high-performance geosynthetic products. Quality assurance, factory price, and fast delivery time are our competitive advantages.