HDPE geomembrana, also known as HDPE geomembane liner or HDPE membrane, is the preferred choice for anti-seepage lining projects due to its accessibility and cost-effectiveness. It is highly resistant to various solvents and is the most commonly used geomembrane liner worldwide. This liner is ideal for large-scale projects requiring UV and ozone resistance, chemical resilience, and high-quality installations. HDPE geomembrane is extensively utilized in landfill and mining projects, where its exceptional properties serve to prevent seepage effectively.

As a professional geomembrane manufacturer and supplier, GEOSINCERE offers a wide range of geomembrana products, including smooth HDPE geomembrane, textured geomembrane, and composite geomembrane, all available at competitive factory prices.

1. What is HDPE Geomembrana?

HDPE geomembrane, used in civil engineering and environmental containment, acts as a synthetic membrane liner to control the flow of fluids, liquids, and gases. Manufactured from different polymeric materials, HDPE geomembrane exhibits impermeable properties, effectively serving as barriers against fluid and gas migration. These flexible geomembranes are designed to withstand challenging environmental conditions, including strong acids and alkalis, providing durable containment solutions for a wide range of projects.

Compared to LLDPE geomembrane, HDPE geomembrane offers superior specific strength and can withstand higher temperatures. Its remarkable resistance to chemicals and ultraviolet radiation enhances its cost-effectiveness. As a result, HDPE geomembrane proves highly advantageous, meeting stringent requirements and delivering long-lasting performance across diverse applications.

2. What Are Properties of HDPE Geomembrana?

2.1 Impermeability

HDPE Geomembrana is designed to create impermeable barriers that prevent the passage of liquids, gases, and contaminants through the material. This property is essential for containing fluids and protecting the environment in various applications especially in landfill.

2.2 Chemical Resistance

HDPE Geomembranas are resistant to chemical degradation and are designed to withstand exposure to a wide range of chemicals, including acids, bases, and hydrocarbons. This makes them suitable for applications where chemical resistance is required, such as in hazardous waste containment.

2.3 UV Resistance

Some HDPE geomembrana is formulated with additives to resist ultraviolet (UV) degradation, ensuring long-term durability when exposed to sunlight. UV resistance is particularly important in applications where geomembranes are exposed to outdoor conditions with long term more than 10 years or 20 years.

2.3 Flexibility

HDPE Geomembranes are flexible and can conform to the contours of the underlying terrain, allowing for installation in various geological conditions and shapes. This flexibility facilitates installation and ensures a secure fit, even on irregular surfaces. It has superior puncture resistance.

2.4 Strength and Tear Resistance

Depending on the application, geomembrana may have specific strength and tear resistance properties to withstand installation and environmental conditions. Reinforced geomembranes may be used in applications where additional strength is required.

2.5 Seaming and Welding Compatibility

Geomembranes are often installed in large sheets, and their seams need to be secure to maintain impermeability. Various seaming and welding techniques are employed to create strong and durable connections between geomembrane sheets.

3. How Thick Is A HDPE Geomembrana?

The thickness of HDPE geomembrane used in anti-seepage and waterproof projects typically ranges from 0.5mm to 3.0mm, which is equivalent to 20 mil to 120 mil. Common thickness options include 0.75mm, 1.0mm, 1.25mm, 1.5mm, 2.0mm, 2.5mm, and 3.0mm. Custom thickness options may also be available through OEM/ODM arrangements. For joint processing, hot-melt welding equipment is commonly used.

4. What Is The Lifespan of HDPE Geomembrana?

Laboratory and field testing indicate that HDPE geomembranes can exhibit a service life of over 70 years, with a 50% degradation threshold. This demonstrates the exceptional durability of HDPE geomembranes and their ability to deliver long-lasting performance across various applications.

However, it’s important to recognize that the actual lifespan of an HDPE geomembrane can be influenced by factors such as environmental conditions, installation quality, and maintenance practices. Regular inspections and proper maintenance procedures are essential to optimize the lifespan of the geomembrane liner.

5. What Is HDPE Geomembrana Used For?

HDPE Geomembranes find extensive applications in various industries:

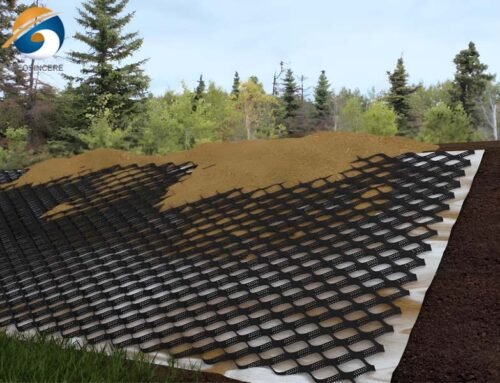

- Landfill Construction: HDPE Geomembranes create impermeable barriers in landfills, preventing the migration of leachate into the environment.

- Mining Operations: HDPE Geomembranes are used for containment and management of tailings, heap leach pads, and other waste materials in the mining industry.

- Water Containment: HDPE Geomembranes are employed in the construction of reservoirs, ponds, and other water containment structures to prevent seepage and regulate water flow.

- Wastewater Treatment: HDPE Geomembranes create containment structures in wastewater treatment facilities, ensuring the controlled containment of treated or untreated water.

- Oil and Gas Industry: HDPE Geomembranes play a crucial role in containing and managing fluids in oil and gas exploration and production, including storage tanks and containment pits.

- Aquaculture: Geomembranes are used in aquaculture ponds to create impermeable liners, preventing water seepage and maintaining a controlled environment for fish or shrimp farming.

- Transportation Infrastructure: HDPE Geomembranes may be utilized in transportation projects for applications such as tunnel waterproofing or as barriers in road construction.

6. What is The Manufacturing Process of HDPE Geomembrane?

The manufacturing process of HDPE geomembranes involves similar basic steps in both the blowing film and flat die extrusion processes, although variations in equipment and techniques exist. These steps include resin melting, extrusion, cooling, and solidification. The choice between the two processes depends on factors such as desired thickness, production efficiency, and available equipment.

Here’s an overview of the production process for each method:

6.1 Blowing Film Extrusion

6.1.1 Raw Material Preparation

Manufacturers carefully select polymer resin pellets to achieve specific geomembrane performance characteristics. The pellet composition directly influences the liner’s flexibility, with softer resins enhancing elongation capabilities. For chemical resistance applications, engineers prioritize high-density polyethylene pellets with specialized additives. Thicker geomembranes require pellets with higher molecular weights to maintain structural integrity. Production teams adjust pellet blends to meet project requirements for UV stability, tensile strength, and environmental stress crack resistance.

6.1.2 Melting and Mixing

Workers feed polymer resin pellets into an extruder where rotating screws mix and compress them. Heating elements gradually melt the pellets into a viscous liquid as they move through the barrel. Technicians often inject specialized additives during this phase to improve UV resistance or flexibility. The screws maintain consistent pressure to ensure proper material flow and homogenization. This controlled melting process creates a uniform polymer blend ready for geomembrane formation.

6.1.3 Extrusion Die and Bubble Formation

The extruder pushes the molten resin through a precisely engineered circular die, shaping it into a continuous tube. Operators carefully inject compressed air into this tubular form, causing it to expand like a balloon. They monitor the inflation process constantly to achieve the exact specified diameter. As the bubble stretches upward, it simultaneously cools and begins to solidify. This controlled expansion determines the geomembrane’s final thickness and width characteristics.

6.1.4 Bubble Cooling and Orientation

The inflated polymer bubble moves upward through a cooling tower where water sprays rapidly chill its surface. Simultaneously, internal air circulation maintains consistent pressure while the material hardens. Technicians adjust the cooling rate carefully to optimize crystalline structure formation in the plastic. This controlled solidification process locks in the geomembrane’s dimensional stability and strength characteristics. Proper cooling ensures the material achieves its specified mechanical properties before further processing.

6.1.5 Bubble Collapse and Flattening

The cooled bubble enters a collapsing frame that gradually flattens it into a double-layer sheet. Precision nip rollers then compress the material while maintaining uniform tension across its width. Operators carefully adjust roller speed to control the final sheet thickness within tight tolerances. This flattening process simultaneously trims the edges to achieve the exact required width. The emerging flat sheet then moves toward winding or cutting stations for final processing.

6.1.6 Surface Treatment (Optional)

The geomembrane sheet passes through a corona treatment unit that exposes its surface to controlled electrical discharge. This process modifies the molecular structure of the surface layer, increasing its surface energy. Operators monitor treatment intensity to achieve optimal bonding characteristics without damaging the material. The enhanced surface improves adhesion for printing, lamination or secondary coating processes. Finally, quality control tests verify the treatment’s effectiveness before the geomembrane proceeds to finishing.

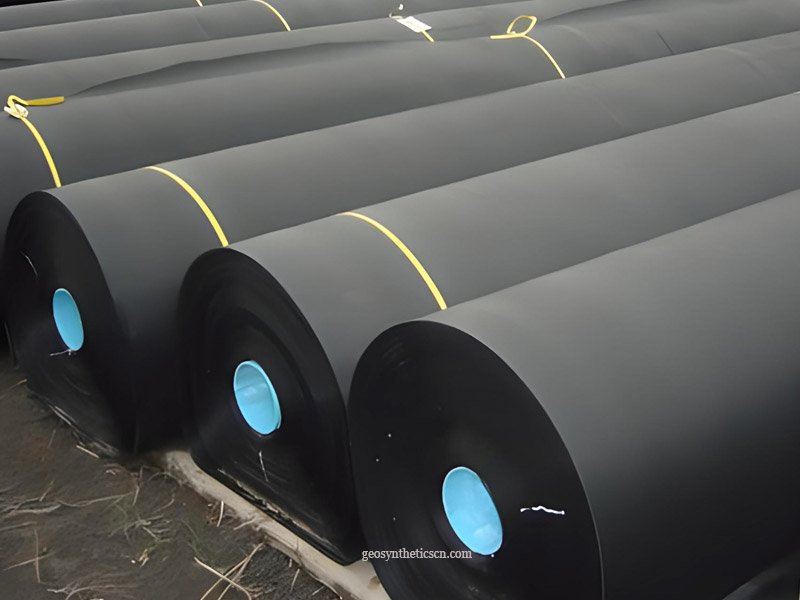

6.1.7 Winding and Packaging

The finished geomembrane sheet is wound onto large rolls or spools for storage and transportation. The rolls may be labeled, wrapped, and packaged according to customer requirements.

6.2 Flat Die Extrusion

6.2.1 Raw Material Preparation

Manufacturers carefully choose polymer resin pellets according to the required HDPE geomembrane specifications. They consider factors like thickness, flexibility and chemical resistance when selecting raw materials. The pellets typically contain additives such as carbon black for UV protection and antioxidants for durability. Production teams blend different resin grades to achieve optimal mechanical properties. This careful formulation ensures the final geomembrane meets project requirements for strength and longevity.

6.2.3 Melting and Mixing

Workers feed the resin pellets into the extruder where rotating screws transport them forward. Heating elements gradually raise the temperature to melt the pellets into a uniform polymer melt. Technicians inject specialized additives during this stage to enhance UV resistance or flexibility. The screws maintain consistent pressure to ensure thorough mixing of all components. This controlled melting process creates a homogeneous material ready for geomembrane formation.

6.2.4 Extrusion Die and Sheet Formation

The molten resin is forced through a flat die, which shapes it into a continuous flat sheet. The die opening determines the width and thickness of the geomembrane sheet.

6.2.5 Cooling and Solidification

The extruded sheet passes through a series of cooling rollers or a water bath to cool and solidify the material. The cooling process sets the desired thickness and mechanical properties of the geomembrane.

6.2.6 Surface Treatment (Optional)

Similar to blowing film extrusion, the surface of the geomembrane may undergo additional treatment processes to enhance surface properties.

6.2.7 Winding and Packaging

The finished geomembrane sheet is wound onto rolls or spools for storage and transportation. It may be labeled, wrapped, and packaged according to customer requirements.

6.3 Comparision of Blowing Film Extrusion vs Flat Die Extrusion of HDPE Geomemrana

6.3.1 Blowing Film Extrusion

This method produces geomembranes in the form of large diameter bubbles that are collapsed and flattened into flat sheets. It is suitable for producing thicker geomembranes with excellent thickness uniformity and mechanical properties.

6.3.2 Flat Die Extrusion

This method directly extrudes flat sheets of geomembranes, offering precise control over width and thickness. It is suitable for producing geomembranes with specific width requirements and is often used for thinner gauge materials.

7. What is the QA procedure for HDPE Geomembrane?

Shandong Geosino have been abide by the high level QC and QAS procedure for hdpe geomembrane quality. Quality assurance (QA) procedures for HDPE geomembrane quality involve systematic measures to ensure that all aspects of the manufacturing process consistently meet predetermined standards and specifications. Here’s a comprehensive outline of the QA procedure for geomembrane quality:

7.1 Establishment of Quality Standards

Define and document specific quality standards, specifications, and performance criteria for geomembranes based on industry standards, regulatory requirements, and customer expectations.

7.2 Quality Planning

Develop a comprehensive quality management plan that outlines the QA procedures, responsibilities, resources, and timelines for geomembrane production. Identify key quality control checkpoints and measures to ensure compliance with established standards.

7.3 Supplier Qualification

Evaluate and select qualified suppliers for raw materials, equipment, and services based on their ability to meet quality requirements and provide consistent, reliable products. Establish criteria for supplier evaluation and performance monitoring.

7.4 Raw Material Control

Implement strict controls and procedures for the procurement, inspection, and testing of raw materials, including polymer resins, additives, fillers, and other components. Ensure that raw materials meet specified quality standards and are free from defects or contaminants.

7.5 Process Control and Monitoring

Establish process control measures to monitor and regulate key parameters during geomembrane production, such as extrusion temperature, pressure, speed, and thickness. Use real-time monitoring systems and sensors to detect deviations from optimal operating conditions.

7.6 Quality Control Inspections

Conduct regular quality control inspections at various stages of the manufacturing process, including raw material preparation, extrusion, welding, testing, and finishing. Use visual inspection methods and testing techniques to verify compliance with quality standards and specifications.

7.7 Testing and Analysis

Perform comprehensive testing and analysis of geomembrane samples to assess mechanical properties, chemical resistance, UV stability, permeability, and other performance characteristics. Use accredited testing laboratories and standardized testing methods to ensure accurate and reliable results.

7.8 Non-Conformance Management

Establish procedures for identifying, documenting, and addressing non-conformities or deviations from quality standards during geomembrane production. Implement corrective and preventive actions to address root causes and prevent recurrence of quality issues.

7.9 Training and Competency

Provide training and competency development programs for production personnel, quality control inspectors, and other staff involved in geomembrane production. Ensure that employees understand their roles and responsibilities in maintaining product quality and adhering to QA procedures.

8. Summary

HDPE geomembrana liners have diverse applications, notably in mining, landfill, and chemical processing. These liners provide effective containment solutions, preventing seepage and protecting the surrounding environment. With their excellent chemical resistance and durability, HDPE geomembrane liners are well-suited for these demanding industries. They offer reliable and long-lasting performance, ensuring the integrity of containment systems and contributing to environmental safety and compliance.

GEOSINCERE, as one of the largest geosynthetics manufacturers in China, has an impressive infrastructure and certification credentials. With over 160 professional staff members and a manufacturing factory spanning 36,000 square meters, GEOSINCERE is well equipped with state-of-the-art geomembrane production lines. This ensures the efficient and high-quality production of geomembrana liners to meet customer demands.

If you are still looking for a reliable partner for HDPE Geomembrane, please turn to our team of GEOSINCERE .