In the ever-evolving field of geosynthetics, innovation continuously drives the development of materials that are more efficient, sustainable, and cost-effective. Among these advancements, Geosynthetic Clay Liners (GCLs), often referred to as bentonite waterproof blankets, have emerged as a cornerstone technology for containment and hydraulic barrier applications. This article provides a comprehensive overview of Geo Clay Liner, exploring their composition, mechanism, applications, advantages, and installation best practices, solidifying their status as an indispensable tool for engineers and environmentalists alike.

1. What is a Geo Clay Liner?

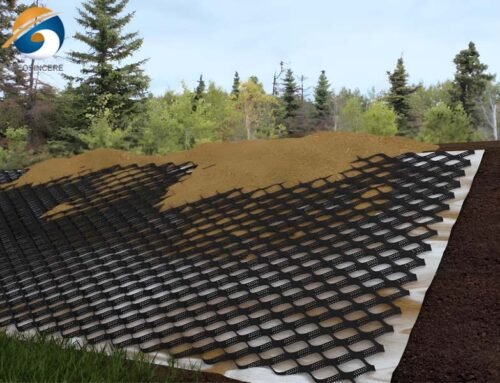

A Geosynthetic Clay Liner is a manufactured hydraulic barrier composed of a layer of sodium bentonite clay bonded between two geotextiles or attached to a geomembrane. This sandwich-like structure combines the low hydraulic conductivity of bentonite with the tensile strength and durability of geosynthetics. Unlike traditional compacted clay liners (CCL), which require extensive excavation and compaction of native soil, GCL are delivered as prefabricated rolls. This allows for rapid deployment and a consistent, high-performance barrier layer with minimal thickness—typically around 1/2 inch (12 mm).

The heart of a GCL’s functionality lies in its core material: sodium bentonite. This clay is renowned for its exceptional swelling capacity. When hydrated with water, sodium bentonite can expand up to 15 times its original volume, forming a dense, impermeable gel that effectively seals voids, cracks, and punctures within the liner system.

2. The Anatomy of a Geo Clay Liner: Materials and Manufacturing

Understanding the components of a GCL is key to appreciating its performance:

2.1 Geo Clay Liner – Bentonite Core

The sodium bentonite used is a naturally occurring clay mineral. Its montmorillonite structure gives it a high cation exchange capacity, which is fundamental to its swelling and sealing properties.

2.2 Geo Clay Liner – Carrier Geotextile

This is the bottom layer, typically a non-woven geotextile. Its primary functions are to contain the bentonite and allow water to pass through from the subgrade to initiate the hydration and swelling process of the clay.

2.3 Geo Clay Liner – Cover Geotextile

This is the top layer, which can be either woven or non-woven. A woven geotextile offers higher tensile strength, while a non-woven geotextile offers greater transmissivity and cushioning. In some products, a geomembrane (like HDPE) is used as the cover layer, creating a composite liner with even lower permeability.

2.4 Geo Clay Liner – Bonding Method

The manufacturing process actively binds the layers together using one of three primary methods: needling, stitching, or adhesive bonding. Firstly, in needling, barbed needles mechanically punch and entangle the fibrous webs, thereby interlocking them into a cohesive unit. Subsequently, for a stronger and more defined bond, operators often use industrial sewing machines to stitch the layers together with thread; this technique not only adds strength but also creates specific patterns. Alternatively, manufacturers may apply adhesives to firmly glue the materials into a single, unified composite. Ultimately, the selection of a specific technique directly depends on the desired properties of the final product, such as its flexibility, durability, and intended application.

2.5 Geo Clay Liner – Needle-Punched

During the needling process, barbed needles actively punch fibers from the cover geotextile through the underlying bentonite layer and directly into the carrier geotextile. As a result, this mechanical action effectively entangles the materials, creating a strong three-dimensional composite structure. Consequently, the method significantly enhances the internal shear strength of the geosynthetic clay liner (GCL). Therefore, this superior mechanical interlock makes needled GCLs particularly ideal for challenging sloped applications, such as landfill caps and reservoir covers, where resistance to shear forces is critical for long-term stability.

2.6 Geo Clay Liner – Stitch-Bonded

Alternatively, manufacturers sometimes choose to stitch the layers together with high-strength threads. While this method is less common than needling or adhesive bonding, it actively binds the materials with a series of precise, locked stitches. This process effectively creates a flexible and durable bond that maintains the material’s permeability. As a result, this technique remains a viable and effective solution for specific applications where other bonding methods are unsuitable.

2.7 Geo Clay Liner – Adhesive-Bonded

In the adhesive bonding process, manufacturers use a specialized glue to actively adhere the bentonite layer to the geotextiles. However, this method requires particularly careful handling throughout the procedure. This is because the dry, powdered bentonite can easily become airborne. Therefore, operators must take great care to control the environment and suppress dust during application. Ultimately, by taking these precautions, this technique effectively creates a uniform and reliable bond while mitigating the health and safety risks associated with bentonite dust inhalation.

3. How Does a Geo Clay Liner Work? The Science of Self-Sealing

The principle behind a GCL’s effectiveness is elegantly simple: hydration and swelling. Once installed and covered, the GCL begins to absorb moisture from the underlying subsoil and/or from precipitation. The sodium bentonite hydrates, swelling to fill any gaps within its own matrix and, crucially, any small punctures or imperfections in the installation. This creates a continuous, low-permeability barrier with a hydraulic conductivity typically on the order of 1 x 10⁻⁹ to 1 x 10⁻¹¹ m/s, rivaling or even surpassing that of a much thicker compacted clay liner.

This self-healing characteristic is a defining advantage, providing a significant factor of safety against potential leaks caused by post-installation settlement or minor damage.

4. Key Applications of Geo Clay Liner

The versatility of GCLs has led to their adoption across a wide range of industries:

- Landfills: Used as part of the composite liner system in base liners and final caps to contain leachate and landfill gas.

- Mining and Heap Leach Pads: Containment of process solutions, tailings, and preventing contamination from acid rock drainage.

- Water and Liquid Containment: Lining for ponds, canals, reservoirs, and irrigation channels to prevent water loss through seepage.

- Infrastructure Projects: Used beneath highways, railroads, and tunnels as a moisture barrier to prevent subgrade weakening and frost heave.

- Environmental Remediation: Capping contaminated sites to prevent rainwater infiltration and the spread of pollutants.

- Secondary Containment: Lining for areas around above-ground storage tanks to contain spills.

5. Advantages Over Traditional Compacted Clay Liners (CCLs)

The rise of GCLs can be attributed to their numerous compelling benefits:

5.1 Space Efficiency

Remarkably, Geo Clay Liners (GCLs) actively conserve valuable landfill airspace. This is because their incredibly thin profile directly replaces a much thicker, 2-3 foot layer of traditional compacted clay. Consequently, this drastic reduction in required thickness significantly reduces excavation volumes during installation. As a result, operators can maximize waste capacity and greatly extend the usable life of the landfill, all while maintaining an equivalent impermeable barrier.

5.2 Rapid Installation

Specifically, construction crews can unroll a pre-manufactured GCL into place exponentially faster than they can source, place, and test a traditional compacted clay layer. This direct comparison highlights a tremendous gain in efficiency. Consequently, this streamlined installation process drastically shortens overall construction timelines. Furthermore, by minimizing the time spent exposed to the elements, it actively reduces potential weather-related delays and risks, leading to a more predictable and secure project schedule.

5.3 Superior Consistency

Because manufacturers produce GCLs under strict factory controls, they can actively guarantee uniform thickness, moisture content, and density throughout the entire product. This rigorous manufacturing process stands in direct contrast to the field compaction of natural clay, which is highly susceptible to environmental and human variability. Consequently, by ensuring consistent, high-quality material properties, factory production effectively eliminates the performance uncertainty inherent in its traditional alternative.

5.4 Exceptional Self-Sealing Capacity

Notably, geosynthetic clay liners (GCLs) possess the unique ability to actively seal around penetrations, such as pipes or structural elements. This critical self-sealing property, driven by the swelling of bentonite when hydrated, ensures a continuous barrier is maintained. In direct contrast, traditional compacted clay liners (CCLs) lack this inherent capability, making them more susceptible to leaks at these critical points. Therefore, this key functional advantage makes GCLs a superior choice for projects where complex interfaces are a primary design concern.

5.5 Cost-Effectiveness

While the initial unit cost of a GCL may be higher, it is crucial to consider the significant savings it generates in other areas. Specifically, GCLs actively reduce expenses by drastically shortening construction time, eliminating the need for extensive material sourcing, and minimizing rigorous on-site quality assurance testing. When these factors are combined, they often result in a lower total project cost. Consequently, this makes geosynthetic clay liners the more economical and efficient choice for the project overall.

5.6 High Performance in Shear

Specifically, the needling process actively entangles the geotextile fibers with the bentonite core. As a direct result, needle-punched GCLs exhibit exceptionally strong internal shear strength. This key property ensures they remain mechanically stable even when installed on steep slopes. Therefore, this makes them a highly reliable and preferred choice for challenging applications such as landfill caps, pond liners, and hilly terrain, where resistance to sliding is critical for long-term performance.

6. Geo Clay Liner Installation Considerations and Best Practices

- Subgrade Preparation: The subgrade must be smooth, firm, and free of sharp rocks, debris, or irregularities that could puncture the liner.

- Hydration: For a GCL to achieve its designed low permeability, it must be adequately hydrated. This can occur naturally from the subsoil or through controlled spraying after installation but before cover soil placement.

- Seaming: Panels are overlapped (typically a minimum of 6 inches) rather than seamed like geomembranes. Bentonite granules or panels are often placed in the overlap to ensure a continuous seal upon hydration. Adhesives can also be used for certain applications.

- Anchoring: On slopes, trench anchors are commonly used to secure the top of the GCL rolls before placing the cover soil.

- Cover Placement: The initial lift of cover soil must be placed carefully, preferably dumped from the top of the slope and spread downward to avoid shifting the liner. The equipment used should have low ground pressure.

7. The Future of GCL Technology

Research and development continue to enhance GCL performance. Future trends include the development of enhanced bentonites (e.g., polymer-treated bentonites) that offer even lower permeability, greater resistance to ionic exchange (which can reduce swelling in harsh chemical environments), and improved self-healing capabilities for larger punctures. Furthermore, the integration of GCLs with other geosynthetics to create multifunctional composite systems is a growing area of innovation.

8. Conclusion

Geosynthetic Clay Liners represent a perfect marriage of natural material science and modern engineering. Their ability to provide a robust, self-healing, and highly impermeable barrier in a thin, easy-to-install package has revolutionized containment design. As environmental regulations become stricter and the demand for sustainable construction practices grows, GCLs will undoubtedly continue to be a critical component in protecting soil and groundwater resources for generations to come.

For more detailed technical specifications, project case studies, or to discuss how GCLs can be integrated into your next project, feel free to reach out to our team GEOSINCERE.We are dedicated to providing cutting-edge geosynthetic solutions and technical support for a wide array of engineering challenges.