In the realm of modern civil engineering and landscaping, effective water management is paramount to ensuring the longevity and sustainability of infrastructure projects. Drain cells, also known as drainage cells or modular drainage systems, have emerged as a critical component in addressing stormwater runoff, soil erosion, and structural protection. These innovative geosynthetic solutions provide a lightweight, high-strength platform for efficient subsurface drainage, making them indispensable in applications ranging from green roofs to retaining walls.

As professionals in the geosynthetics industry, we understand the importance of balancing performance with budget constraints. The drain cell price can vary significantly based on several factors, typically ranging from $0.52 to $4.60 per square meter for raw materials in 2025, excluding installation and ancillary costs. When factoring in full project implementation, total expenses may climb to $10–$25 per square meter, offering substantial long-term savings through reduced maintenance and enhanced durability. This comprehensive guide delves into the intricacies of drain cell pricing, providing actionable insights to help engineers, contractors, and project managers make informed decisions. Whether you’re designing a rooftop garden or fortifying a civil engineering foundation, understanding these costs empowers you to optimize your investment while achieving superior drainage efficiency.

The global Drainage products market, valued at over $13 billion in 2024, continues to grow at a CAGR of 6.5%, driven by urbanization and sustainable infrastructure demands. Within this landscape, drain cells represent a cost-effective evolution from traditional gravel or pipe-based systems, potentially reducing material needs by 30–50% and installation time by up to 40%. In the following sections, we’ll explore the fundamentals of drain cells, dissect the key pricing determinants, and outline strategies for selection and implementation. By the end, you’ll have the knowledge to navigate drain cell costs with confidence, ensuring your projects deliver both economic and environmental value.

1. What Are Drain Cells?

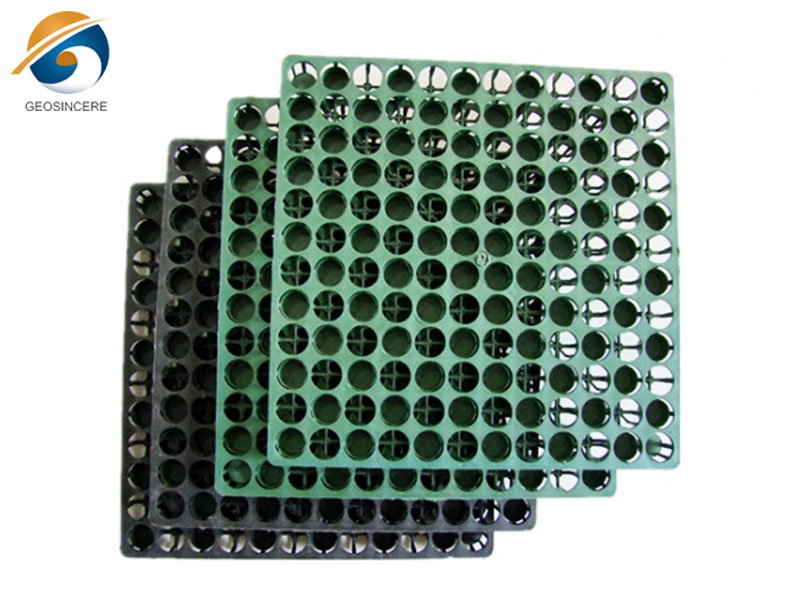

Drain cells are modular, geosynthetic drainage systems engineered to facilitate the controlled movement of water while supporting structural loads. Composed primarily of high-density polyethylene (HDPE) or polypropylene (PP), these units feature a honeycomb or cuspated structure that creates interconnected voids—typically occupying 90–95% of the volume—for rapid water percolation. Unlike conventional drainage methods that rely on aggregate fills, drain cells provide a lightweight alternative (weighing as little as 225 grams per unit) with exceptional compressive strength, often exceeding 800–2,000 kPa, making them suitable for high-traffic areas like pavements and sports fields.

At their core, drain cells function by separating impermeable surfaces (such as concrete slabs or waterproof membranes) from underlying soil or substrates, allowing excess moisture to drain laterally or vertically without ponding or hydrostatic pressure buildup. This design not only prevents water damage but also promotes root aeration in vegetated applications, contributing to healthier landscapes. Standard specifications include thicknesses from 20–50 mm, panel dimensions of 500 mm x 250 mm or 610 mm x 410 mm, and integration with geotextile filters to prevent clogging from fines.

Types of Drain Cells

Drain cells are categorized based on their structural design and intended use, each offering distinct performance parameters:

- Modular Honeycomb Cells: The most common type, featuring interlocking plastic grids for horizontal or vertical drainage. Ideal for landscaping and civil engineering, with void ratios up to 95% and flow rates exceeding 1.5 m³/s per linear meter under 2% hydraulic gradient. These are often wrapped in non-woven geotextile (100–200 gsm) for filtration.

- Sheet-Based Drain Cells: Thinner (10–20 mm) and flexible, resembling dimpled membranes. Suited for vertical applications like retaining walls, with lower compressive strength (300–500 kPa) but higher flexibility for irregular surfaces.

- Geocomposite Drain Cells: Hybrid systems combining cells with geonets or geospacers for enhanced vertical drainage. Used in roofing and podium decks, these provide tensile strengths up to 20 kN/m and UV resistance for exposed installations.

Materials play a pivotal role in durability: HDPE variants offer superior chemical resistance and a 50+ year lifespan in buried conditions, while recycled PP options prioritize sustainability at a slight trade-off in rigidity. Key parameters to evaluate include:

| Parameter | Typical Range | Impact on Performance |

| Compressive Strength | 800–2,000 kPa | Determines load-bearing for vehicular areas |

| Void Ratio | 90–95% | Influences drainage capacity (higher = faster flow) |

| Thickness | 20–50 mm | Balances storage volume vs. structural height |

| Flow Rate | 1.0–2.5 m³/s per m width | Critical for high-rainfall zones |

| Geotextile GSM | 100–300 g/m² | Prevents silt ingress; higher for fine soils |

These specifications ensure compliance with standards like ASTM D4716 for geocomposites, underscoring the engineering precision behind drain cells.

Applications of Drain Cells

The versatility of drain cells spans multiple sectors, where they mitigate water-related risks and enhance project resilience:

- Landscaping and Green Roofs: In terrace gardens and podium slabs, drain cells channel excess water away from root zones, reducing erosion by 70% and enabling 20–30% soil volume savings compared to gravel layers. For instance, a 1,000 m² rooftop garden might incorporate 25 mm cells to support sedum planting while protecting underlying membranes.

- Civil Engineering and Infrastructure: Beneath pavements and sports fields, they alleviate hydrostatic pressure, extending surface life by 15–20 years. In retaining walls, vertical installations prevent soil saturation, with studies showing 40% reduced failure rates in cohesive soils.

- Building Foundations and Waterproofing: As a protective layer over damp-proof membranes, drain cells facilitate gas and vapor venting, crucial in urban basements where groundwater levels fluctuate.

By integrating these systems early in design, projects achieve compliance with LEED or similar green building certifications, amplifying both functional and fiscal benefits.

2. How Much Does a Drain Cell Cost?

The drain cell price is not a one-size-fits-all figure; it hinges on a confluence of material, design, and logistical variables. On average, raw drain cell materials cost $1.50–$3.50 per square meter in 2025, influenced by global resin prices and manufacturing efficiencies. Full installed systems, including geotextiles and labor, range from $10–$25 per square meter, with ROI realized through 30–50% lower lifecycle maintenance compared to traditional methods. This section breaks down the primary cost drivers, equipping you with data to forecast budgets accurately.

2.1 Drain Cell Price – Material Type

The choice of polymer fundamentally dictates both upfront and enduring expenses. HDPE drain cells, prized for their robustness, command $2.00–$4.00 per square meter due to higher raw material costs ($1.20–$1.80/kg for virgin resin). In contrast, PP-based units, often recycled, range from $0.96–$1.50 per square meter, appealing for eco-conscious projects.

- HDPE Drain Cells: Excellent chemical resistance (pH 1–14) and UV stability; lifespan 50–100 years. Applications: Harsh environments like industrial sites. Advantages: 25% higher compressive strength (up to 2,000 kPa); drawbacks: 15–20% premium over PP.

- PP Drain Cells: Lightweight (density 0.90 g/cm³) and recyclable; ideal for green roofs. Cost savings: Up to 30% vs. HDPE, with comparable flow rates (1.5 m³/s/m). Example: A 500 m² planter box using PP cells totals $750 in materials alone.

Geocomposites add $0.50–$1.00 per square meter for integrated layers, enhancing filtration but increasing complexity.

2.2 Drain Cell Price – Thickness

Thickness directly correlates with hydraulic capacity and load support, influencing price by 20–40%. Standard 20 mm cells cost $1.00–$2.00 per square meter, suitable for low-load landscaping. Thicker 40–50 mm variants, for vehicular applications, escalate to $3.00–$5.00 per square meter due to increased resin volume.

- 20–30 mm Thickness: For horizontal drainage in gardens; provides 10–15 L/m² storage. Cost efficiency: Balances drainage (95% voids) with minimal height impact.

- 40–50 mm Thickness: Vertical or high-load uses; supports 500–1,000 kPa. Example: In a 200 m² parking deck, 50 mm cells add $600–$1,000 but prevent $5,000+ in annual repairs from water damage.

Data indicates that optimal thickness selection can yield 15% cost reductions in medium-scale projects by avoiding over-specification.

2.3 Drain Cell Price – Project Size and Scale

Economies of scale profoundly impact pricing: Small projects (<500 m²) incur $3.50–$6.00 per square meter due to minimum order fees, while large-scale (>5,000 m²) deployments drop to $0.80–$2.00 per square meter through bulk discounts.

- Small-Scale Projects: Custom cutting and shipping inflate costs by 25%; e.g., a residential garden (100 m²) at $400 total.

- Large-Scale Projects: Volume purchases from manufacturers like Geosincere reduce per-unit pricing by 40%. Civil engineering bids for highways might save $10,000+ on 10,000 m² installations.

| Project Size | Material Cost per m² | Total Installed Cost per m² | Savings Potential |

| <500 m² | $2.50–$4.00 | $15–$25 | Baseline |

| 500–5,000 m² | $1.50–$3.00 | $12–$20 | 15–20% |

| >5,000 m² | $0.80–$2.00 | $10–$15 | 30–40% |

2.4 Drain Cell Price – Installation Method and Labor

Installation represents 40–60% of total expenditure, varying by technique and site conditions. Modular interlocking (DIY-friendly) costs $5–$10 per square meter in labor, while adhered or welded systems for sloped surfaces add $8–$15.

- Horizontal Installation: Roll-out on flat decks; 1–2 days for 1,000 m² with a two-person crew ($2,000 labor).

- Vertical Installation: Fixed to walls with clips; requires scaffolding, inflating costs by 30% in urban settings.

Factors like soil type (clay vs. sand) and access (rooftop cranes) can double labor rates, emphasizing pre-planning.

2.5 Drain Cell Price – Raw Material Quality

Virgin resins ensure peak performance but cost 20–30% more than recycled blends ($1.50 vs. $1.10/kg). Additives like UV stabilizers add $0.20–$0.50 per square meter.

- Virgin HDPE/PP: Meets ASTM standards; zero defects rate, ideal for critical infrastructure.

- Recycled Materials: Sustainable option with 95% performance parity; e.g., Geosincere’s eco-line saves 15% without compromising 1,000 kPa strength.

Quality audits, including tensile testing (min. 8 kN/m), justify premiums by averting failures costing $1,000+ per incident.

2.6 Drain Cell Price – Transportation and Logistics

Freight accounts for 10–15% of costs, with domestic shipping at $0.10–$0.30 per square meter versus $0.50–$1.00 for international. Roll sizes (up to 100 m²) minimize handling fees.

- Local Sourcing: Reduces carbon footprint and costs by 20%; e.g., from Shandong suppliers to U.S. ports.

- Global Import: Tariffs and container rates (2025 avg. $3,000/20-ft) add variability; bulk orders mitigate this.

2.7 Drain Cell Price – Maintenance and Lifetime Costs

While initial outlay is higher than gravel ($5–$10/m³), drain cells’ 50-year lifespan yields a 5:1 ROI through negligible upkeep (cleaning every 5–10 years at $0.50/m²).

- Long-Term Savings: Prevents $2,000–$5,000/m² in repairs from water ingress.

- Warranty Considerations: 20–30-year guarantees from reputable manufacturers offset risks.

3. How to Choose the Right Drain Cell

Selecting the optimal drain cell requires a systematic evaluation of project demands, balancing cost with performance. Begin by mapping site hydrology—rainfall intensity (e.g., 100 mm/hr in tropical zones) and soil permeability—to determine required flow rates.

Assess Project Requirements

Align specs with application: For roofing, prioritize UV-resistant HDPE (min. 1,500 kPa); for foundations, focus on geotextile integration (200 gsm).

- Hydraulic Needs: Calculate storage (e.g., 20 L/m² for green roofs).

- Load Factors: Vehicular? Opt for 2,000 kPa models.

Prioritize Quality and Certifications

Insist on ISO 9001-certified products with third-party testing (e.g., EN 12955 for compressive strength). Avoid unverified imports that fail prematurely, eroding 20% of savings.

Evaluate Installation Needs

Modular designs cut labor by 40%; assess site access and crew expertise.

Consider Long-Term Costs and ROI

Model NPV: A $15/m² investment in premium cells recovers via 30% reduced maintenance over 20 years.

Compare Suppliers

Vet manufacturers like Shandong Geosino for competitive pricing ($1.20–$3.00/m²) and customization.

4. Industry Trends Affecting Drain Cell Price

Evolving market dynamics are reshaping drain cell pricing in 2025. Raw polymer costs, tied to oil prices ($70–$90/barrel), fluctuate 10–15% annually, but recycled content mandates (e.g., EU Green Deal) lower them by 20% for sustainable variants.

- Sustainability Push: Bio-based additives reduce virgin resin dependency, cutting costs 15–25%.

- Technological Advances: Smart sensors in cells ($0.50/m² add-on) enable predictive maintenance, boosting ROI by 10%.

- Wider Roll Formats: Larger panels (1 m x 5 m) trim installation by 20%, per global adoption in Asia-Pacific markets.

- Regulatory Shifts: Stricter stormwater codes favor cells, increasing demand and stabilizing prices at $1.80/m² average.

These trends signal a 5–7% price stabilization, favoring early adopters.

Conclusion

Navigating drain cell prices demands a nuanced understanding of materials, scales, and applications, with costs averaging $1.50–$3.50 per square meter for materials and $10–$25 installed. By prioritizing quality from trusted suppliers and leveraging economies of scale, projects can achieve 30–50% savings over traditional drainage while enhancing sustainability and performance. As urbanization accelerates, investing in robust drain cells not only safeguards infrastructure but also delivers measurable ROI through durability and efficiency.

For tailored quotes and expert guidance on drain cell solutions, contact Shandong Geosino New Material Co., Ltd (Geosincere Geosynthetics) at sales@geosyntheticscn.com.Their HDPE and PP drainage cells, backed by rigorous testing, ensure your project meets both budgetary and performance benchmarks.