An HDPE liner (High-Density Polyethylene liner) is a geomembrane made from high-density polyethylene resin, designed to provide a durable, impermeable barrier in various containment applications.

HDPE liners are often used to line aquaponics, ponds, troughs, bio swales, canals, drainage, mud runners, slip-n-slides, and other water retention and containment applications. Other uses include root barrier, piping, and slip sheets, along with helping to divert water toward drain pipe debris netting to help capture debris and prevent it from entering stormwater systems.

1. HDPE liner Features

- Environmental friendly formula:The raw materials we have used meet the international standards, non-toxic, environmentally friendly. It is used for a variety of environmental protection, agriculture and aquaculture waterproof and anti leakage.

- Aging resistance property:With excellent anti-aging, anti ultraviolet and anti decomposition ability.

- High mechanical strength:Good mechanical strength, there are a variety of specifications to meet the different programs of electrical construction, water conservancy project waterproof.

- Chemical stability:Excellent stability, acid and alkali, anti salt solution, oil, alcohol and other 80 kinds of chemical medium corrosion, so it is widely used in sewage treatment, landfill.

- Puncture resistance:It has excellent puncture resistance, resist to most of the plant roots, so HDPE geomembrane is roof planting required products.

- High impervious coefficient:With perfect waterproof effect that ordinary waterproof materials can not match, it is recommended in some high waterproof requirements of the projects.

- Fast construction speed:HDPE geomembrane features high flexibility, with a variety of lay forms to meet the requirements of different projects, convenient and fast construction.

- Low cost:It adopts new technology, the production process is more scientific and efficient, so the product cost is lower than the traditional waterproof material. And it is the best product for water storage and seepage control.

- Good weather resistance:Using temperature range: -70°C – 70°C.

- Long service life:The service life can be up to 50-70 years.

2. How Thick Is HDPE Liner ?

The thickness of HDPE liner is 0.75 mm – 3.0 mm(30mil -120mil). Common thicknesses are 0.3mm, 0.5mm, 0.75mm,1.5mm,etc .

Roll size(width*length) can be customized :

Usually:7m*105m,7m*140m,7m*210m,7m*280m,7m*350m,7m*420m,7m*525m .Different thicknesses can suit different applications . Such as for the fish pond , the thickness usually will need 0.5mm or 0.75mm to build. If you are unsure of the thickness of HDPE geomembrane required for your project, please contact us.

3. Advantages and Disadvantages of HDPE liner :

High-Density Polyethylene (HDPE) liners are widely used due to their durability, chemical resistance, UV stability, and flexibility. Some key applications include:

3.1 Environmental Protection & Waste Containment

- Landfills & Waste Dumps: HDPE liners prevent leachate (toxic liquid) from contaminating soil and groundwater.

- Hazardous Waste Storage: Used in containment areas for industrial and chemical waste.

- Mining (Heap Leach Pads, Tailings Ponds): Prevents toxic chemicals (e.g., cyanide, sulfuric acid) from seeping into the environment.

3.2 Water & Liquid Storage

- Potable Water Reservoirs: Safe for drinking water storage due to non-toxicity.

- Sewage & Wastewater Treatment Ponds:Prevents leakage and groundwater contamination.

- Agricultural Ponds (Irrigation, Aquaculture):Used in fish farms, irrigation ponds, and livestock watering systems.

3.3 Industrial Applications

- Chemical Storage Tanks & Secondary Containment: Protects against spills in industries handling acids, fuels, and solvents.

- Oil & Gas Industry:Used in oilfield pits, frac ponds, and spill containment.

3.4 Construction & Infrastructure

- Tunnel & Underground Waterproofing:Prevents water seepage in tunnels and basements.

- Roofing Membranes: Used in green roofs and waterproofing applications.

- Decorative Ponds & Lakes: Provides a leak-proof barrier in artificial water bodies.

3.5 Agriculture & Aquaculture

- Biogas Digesters:Used in anaerobic digestion plants to contain organic waste and methane.

- Hydroponics & Greenhouse Flooring: Prevents root penetration and soil contamination.

3.6 Floating Covers

- Evaporation Control:Used in reservoirs and ponds to reduce water loss.

- Odor & Gas Containment: Covers wastewater lagoons to trap harmful gases (e.g., H₂S, methane).

3.7 Advantages of HDPE Liners

- Chemical Resistance– Resists acids, alkalis, and solvents.

- UV & Weather Resistance– Long lifespan (20-30+ years) even in harsh climates.

- Flexibility & Strength – Can withstand ground movement and heavy loads.

- Low Permeability – Excellent barrier against liquids and gases.

- HDPE liners are a cost-effective and reliable solution for containment and protection in various industries. Would you like details on installation or specific use cases?

3.8 HDPE liner Disadvantages

- Poor flexibility

- Heavy weight makes it more expensive to ship, difficult to install

- Less custom fabrication; mostly welded on-location

- Lowerresistance to stress cracking

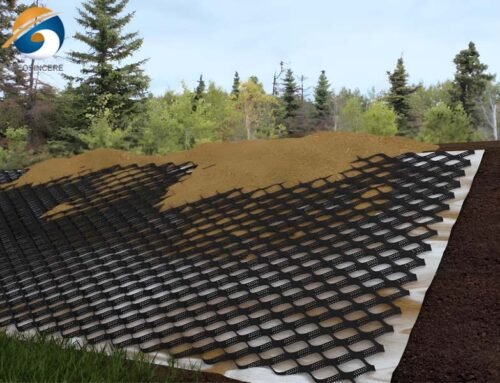

4. Applications of HDPE liner :

HDPE liner is an excellent product for large applications that require UV and Ozone resistance, chemical resistance or high-quality installations.

HDPE liner offers the most cost effective liner for large projects.This product is successfully used in landfills, waste water treatment lagoons, animal waste lagoons and mining applications.

HDPE liner Applications :

- Landfill Liner & Caps

- Animal Waste Lagoons

- Golf Course Ponds

- Gas Collection Covers

- Pond & Lake Liners

- Irrigation Reservoirs

- Waste Water Treatment Lagoons

- Mining Tailing & Heap Leach Pads

- Canal Lining

From reservoirs and lagoons to municipal water ponds High Density Polyethylene (HDPE) is the most common field fabricated geomembrane material.

HDPE liners are both tough and flexible, with high resistance to chemicals and corrosion. HDPE liners are among the most durable and long-lasting polyethylene liners on the market. They can be fusion weld together, forming permanent seals in the field. The fusion welding aspect requires an experienced welder and related equipment to ensure a quality installation. HDPE liners are safe for both fish and plants. Overall, HDPE liners are very cost-effective and have among the highest service lifespan of all polyethylene liners.

5. How to choose Hight-Quality HDPE Liner Supplier :

Shandong Geosino New Material Co.,Ltd (Brand:Geosincere) is the professional HDPE liners and geosynthetics manufacturer and wholesaler located in Shandong Province, China. We are an professional manufacturer, exporter and wholesaler for such geosynthetic products as HDPE liners, geotextiles, geogrids, geocells, geosynthetic clay liners (GCLs), drainage boards, etc.

GEOSINCERE is always committed to HDPE liners research and development, manufacturing and installation services. We can provide customers with most extensive lines of HDPE liners and geotextiles for projects as civil engeering, Gold mining, Copper Mining,Road Construction,Landfill, Agriculture and aquaculture engineering applications.

We have been exporting HDPE liners and geosynthetics to over 60 countries such as Australia, France, Sweden, UK, Hong Kong, Hungary, New Zealand, Poland, Mexico, Ecuador, Brazil, Pakistan, Bangladesh, Thailand, Vietnam, Malaysia, Indonesia, Singapore, Philippines, Sri Lanka, India, UAE, Saudi Arabia, Qatar, Kenya, Ghana, Ethiopia, Somalia, Nigeria, South Africa, Switzerland, Mongolia, etc. They choose Geosincere as partner for more than 10 years.

GEOSINCERE has been keeping on investing in technological innovation, manufacturing facilities improvement and turnkey engineering abilities. We have invested 10 million dollars into our manufacturing factory which is equipped with state-of-the-art automatic production lines to manufacture high quality HDPE liners and other geosynthetics with optimized processes. Our extensive lines of geosynthetics products are well known for their ensured quality, high performance, excellent durability and best cost effectiveness.

8 reasons to choose Geosincere :

- Premium ingredients and formulas

- IGS memberHDPE liners factory

- All sizes are produced

- Good quality, ex-factory price.

- Safe and sturdy packaging.

- Fast production cycle

- Provide free samples

- Professional guidance services

6. Choose a reliable supplier to quote price for you :

GEOSINCERE has been keeping on investing in technological innovation, manufacturing facilities improvement and turnkey engineering abilities. We have invested 10 million dollars into our manufacturing factory which is equipped with state-of-the-art automatic production lines to manufacture high quality HDPE geomembranes and other geosynthetics with optimized processes. Our extensive lines of geosynthetics products are well known for their ensured quality, high performance, excellent durability and best cost effectiveness.

GEOSINCERE brand HDPE geomembranes and other geosynthetics products and solutions can meet your requirements by our solid technologies, innovative engineering solutions and excellent customer services. GEOSINCERE always tries our best to solve the most complex civil, mining and environmental challenges with our innovative and high performance geosynthetic products. Quality assurance, factory price and fast delivery time are our competitive advantages.