In the realm of modern civil engineering, environmental protection, and water resource management, the imperative for reliable, durable, and cost-effective containment solutions is paramount. Among the various engineered materials developed to meet this demand, High quality geomembrane has emerged as a globally recognized standard for impermeable lining systems. Specifically, the 1mm thickness variant represents a critical product category that balances performance with economic practicality. This article provides an in-depth exploration of the 1mm HDPE geomembrane, elucidating its fundamental characteristics, manufacturing process, and the extensive spectrum of its professional applications.

1. What Is 1mm HDPE Geomembrane?

1.1 Definition and Material Composition

A 1mm HDPE geomembrane is a flexible, impermeable liner manufactured from high-density polyethylene (HDPE) resin. The base polymer is carefully compounded with carbon black (2–3%) for ultraviolet resistance, along with antioxidants and thermal stabilizers to ensure durability in aggressive environments.

1.2 Manufacturing Process

Producers typically use advanced extrusion techniques—either flat-die calendering or blown-film extrusion—to create continuous sheets with uniform thickness and width. This process guarantees consistency, structural integrity, and reliable impermeability across large-scale installations.

1.3 Significance of the 1mm Thickness

The 1.0 mm (40 mil) thickness specification represents a balanced choice between mechanical strength, deformation resistance, and cost efficiency. It provides sufficient robustness for medium- to heavy-duty containment projects, making it one of the most widely applied specifications in civil, environmental, and industrial engineering.

2. Key Properties and Advantages of 1mm HDPE Geomembrane

The widespread adoption of 1mm HDPE geomembrane is attributable to its superior engineering properties:

2.1 1mm HDPE Geomembrane – Exceptional Impermeability

HDPE geomembranes possess an extremely low hydraulic conductivity, typically less than 1 x 10⁻¹³ m/s. This creates an virtually impervious barrier that effectively prevents the migration of liquids, vapors, and contaminants, protecting soil and groundwater resources.

2.2 1mm HDPE Geomembrane – High Mechanical Strength

A 1mm thickness provides excellent tensile strength, tear resistance, and puncture resistance. This allows the liner to withstand significant stresses during installation and service, including subgrade settlement and overburden pressure from waste or water.

2.3 1mm HDPE Geomembrane – Outstanding Chemical Resistance

HDPE’s highly inert nature actively resists a wide range of chemical attacks; specifically, it withstands strong acids, alkalis, salts, and industrial solvents. Consequently, this property becomes indispensable for containment applications. For instance, it reliably secures challenging materials like hazardous leachate, aggressive industrial waste, and other harmful chemicals. Therefore, HDPE geomembrane offers essential, long-term protection for the environment and project integrity.

2.4 1mm HDPE Geomembrane – Durability and Long Service Life

Additionally, the inclusion of carbon black actively provides the geomembrane with superior resistance to damaging ultraviolet (UV) radiation, oxidation, and extreme temperature fluctuations ranging from -60°C to 80°C. As a direct result of this robust formulation and when properly installed, a 1mm HDPE geomembrane effectively ensures long-term performance. Furthermore, by also protecting it from mechanical stresses, this geomembrane can confidently achieve a service life exceeding 50 years. Therefore, it delivers exceptional and reliable durability for a wide array of projects.

2.5 1mm HDPE Geomembrane – Cost-Effectiveness

Compared to thicker gauges like 1.5mm or 2.0mm, the 1mm geomembrane significantly reduces material costs. Moreover, it maintains robust performance across numerous applications, ensuring reliable containment and protection. Consequently, it delivers an excellent return on investment by balancing economy and functionality. Furthermore, its flexibility and ease of installation enhance its practicality. Therefore, for projects requiring effective yet economical solutions, the 1mm geomembrane stands out as a smart and efficient choice.

3. Critical Applications of 1mm HDPE Geomembrane

The versatility of 1mm HDPE geomembrane allows it to be deployed across numerous industries. Its primary function is always containment, but the specific contexts vary widely.

3.1 1mm HDPE Geomembrane – Environmental Containment

- Landfill Liners and Caps: This is one of the most crucial applications. The 1mm geomembrane is used as a primary or secondary liner in municipal solid waste (MSW) landfills and hazardous waste landfills to contain leachate and landfill gas, preventing environmental pollution. It is also used as a final cap to close landfills and minimize precipitation infiltration.

- Wastewater and Treatment Lagoons: It lines anaerobic and aerobic treatment lagoons, equalization basins, and storage ponds in municipal and industrial wastewater treatment plants, ensuring no seepage contaminates the local aquifer.

3.2 1mm HDPE Geomembrane – Water and Hydraulic Engineering

- Potable Water Reservoirs: Used to line reservoirs for drinking water, preventing loss through seepage and protecting the water from external contamination.

- Irrigation Canals and Storage Ponds:In agricultural projects, it is deployed to line canals and storage ponds, significantly improving water conservation efficiency in arid regions.

- Decorative and Recreational Water Features:Used in the construction of artificial lakes, ponds, and golf course water hazards due to its reliability and ease of installation.

3.3 1mm HDPE Geomembrane – Mining and Energy Sector

- Heap Leach Pads: In gold, copper, and uranium mining, dilute chemical solutions are sprayed over ore piles to dissolve valuable metals. The 1mm HDPE liner captures the pregnant solution, preventing loss and environmental damage.

- Tailings Impoundments: It forms the basal liner for tailings dams, containing the fine-grained, often chemically reactive, waste byproducts of mining operations.

- Secondary Containment: It is used as a liner for secondary containment areas around fuel storage tanks, transformer yards, and chemical processing plants to contain spills in accordance with environmental regulations.

3.4 1mm HDPE Geomembrane – Aquaculture and Agriculture

- Fish and Shrimp Ponds:Provides a clean, controllable environment for aquaculture by preventing water loss and isolating the culture from underlying soil, which helps in managing diseases and improving yield.

- Biogas Digester Covers: Used as flexible floating covers on anaerobic digesters in agricultural and waste treatment facilities to capture biogas (methane) for energy production.

4. Installation and Welding Considerations for 1mm Geomembrane

The performance of the liner is entirely dependent on the quality of its installation. Key steps include:

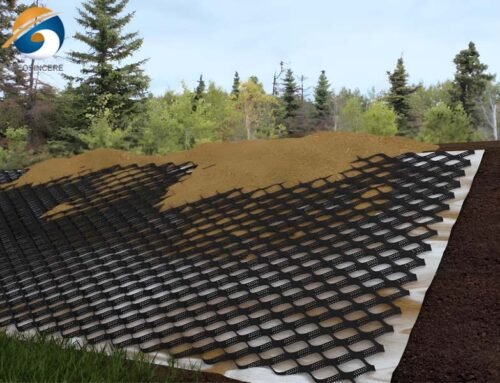

- Subgrade Preparation: The foundation must be meticulously graded, compacted, and free of sharp objects, rocks, or roots that could puncture the liner. A geotextile protection layer is often used underneath.

- Panel Deployment:Rolls are deployed on the prepared subgrade, with panels overlapping by a specified amount (typically 100-150mm) to facilitate welding.

- Welding: Creating continuous, robust seams is critical. The two primary methods are:

- Dual-Wedge Hot Welding: A automated machine passes over the overlap, heating both sheets and applying pressure to fuse them together. This creates a primary and secondary weld channel, which can be air-pressure tested for integrity.

- Extrusion Welding: A hand-held tool extrudes a molten bead of HDPE material that bonds the overlapping sheets or details around penetrations. This method is used for patches, repairs, and complex areas.

- Quality Assurance/Quality Control (QA/QC): Every weld is non-destructively tested (e.g., air pressure testing on dual-weld seams) and destructively tested (samples sent to a lab for peel and shear tests) to ensure seam strength exceeds that of the parent material.

5. How to Choose the Right 1mm HDPE Geomembrane?

Choosing the most suitable 1mm HDPE geomembrane requires a structured evaluation of multiple technical and application-specific factors. Below is a step-by-step guide to support your decision-making process.

5.1 Determine Project Requirements

Begin by clearly defining the primary function of the geomembrane. Will it be used for containment, lining, barrier protection, or capping? Applications such as decorative ponds, agricultural lagoons, secondary containment, and temporary covers often benefit from the balance of performance and economy offered by a 1mm thickness.

5.2 Verify Key Material Properties

-

Carbon Black Content: Ensure the geomembrane contains 2–3% carbon black. This is essential for long-term resistance to UV degradation, oxidation, and extreme temperature variations (–60°C to 80°C).

-

Chemical Resistance: Confirm compatibility with the substances it will contact. HDPE is highly inert, offering excellent resistance to acids, alkalis, salts, and many industrial chemicals, making it ideal for leachate ponds or agricultural applications.

5.3 Evaluate Quality and Certification

Always choose a geomembrane that complies with internationally recognized standards. Look for certification against GRI GM13 or comparable specifications. This guarantees consistent material properties, thickness, and tensile strength.

5.4 Consider Surface Texture

Select the appropriate texture based on slope stability requirements:

-

Smooth Surface: Suitable for flat base liners and applications where low friction is acceptable.

-

Textured Surface: Essential for slopes, dams, or landfills to enhance interface shear strength and prevent slippage.

5.5 Assess Installation and Environmental Conditions

Finally, factor in the installation environment. A robust subgrade preparation and proper protection geotextiles are recommended, especially in challenging soils. When correctly installed and protected, a 1mm HDPE geomembrane can deliver a service life exceeding 50 years.

By systematically reviewing these aspects—application, material specs, certifications, surface type, and installation conditions—you can confidently select a 1mm HDPE geomembrane that ensures performance, durability, and excellent return on investment.

6. Conclusion

The 1mm HDPE geomembrane is far more than just a simple plastic sheet; it is a highly engineered solution that plays a vital role in protecting our environment and conserving vital resources. Its optimal blend of thickness, mechanical robustness, chemical inertness, and longevity makes it an indispensable material for engineers and project developers across the globe. From securing the base of a landfill to ensuring the efficiency of a water reservoir, its applications are foundational to sustainable, modern infrastructure. As technology advances, the formulations and installation techniques for HDPE geomembranes continue to improve, further solidifying their status as a cornerstone of geosynthetic engineering. Selecting a high-quality 1mm HDPE geomembrane and ensuring its expert installation is a proven investment in the safety, compliance, and success of any containment project. If you have any questions, please contact the geotechnical materials expert – GEOSINCERE.