Geosynthetics are kinds of synthetic materials which widely used in civil engineering, construction project, and environmental engineering works to improve the foundation ,slope performance, durability, and sustainability of infrastructure projects. These Geosynthetics materials are manufactured from a polymers or composite of different polymers and include a wide range of products designed to address specific engineering challenges.

As the geosynthetics manufacturer and supplier, GEOSINCERE offers various geo material including geotextile, geomembrane, geogrid and GCLs at best best factory price.

1. What Are Geosynthetics?

Geosynthetics are engineered materials designed to enhance soil conditions and improve the performance of geotechnical materials in construction and civil engineering projects. These man-made materials are typically composed of petrochemical-based polymers that are biologically inert and resistant to decomposition caused by bacteria or fungi.

Geosynthetics play a vital role in geotechnical and civil engineering applications, offering a range of functions including reinforcement, separation, filtration, drainage, and containment. They are utilized to strengthen soil, rock, or other geotechnical materials, ensuring stability and preventing soil erosion.

Commonly used polymers in geosynthetics manufacturing include polyethylene, polypropylene, polyester, and other synthetic materials. These polymers are selected for their durability, resistance to environmental factors, and compatibility with different soil conditions.

Reinforcement geosynthetics, such as geogrids and geotextiles, provide added strength to soils, allowing them to withstand heavy loads and improve stability. Separation geosynthetics act as a barrier between dissimilar soil layers, preventing mixing and maintaining the integrity of the structure. Filtration geosynthetics allow water to pass through while retaining soil particles, ensuring proper drainage and preventing clogging. Drainage geosynthetics facilitate the efficient flow of water, preventing the buildup of hydrostatic pressure. Containment geosynthetics, such as geomembranes, are impermeable barriers used for waste containment, water containment, and environmental protection.

Overall, geosynthetics offer versatile solutions in geotechnical and civil engineering, providing improved performance, increased durability, and enhanced sustainability in construction projects. Their use contributes to the efficient and cost-effective execution of infrastructure development while minimizing environmental impact.

2. What Are The Most Common Geosynthetics?

Geotextile, geomembrane, geogrid and Geosynthetic Clay Liners (GCLs) are indeed among the most common geosynthetics used for containment applications. Each of these materials serves a specific purpose in providing effective containment solutions in various construction and environmental projects.

2.1 Geotextile

Geotextiles are permeable fabrics made from synthetic fibers or natural materials. They are primarily used for separation and filtration functions in containment applications. Geotextiles act as a barrier between dissimilar soil layers, preventing the mixing of materials and maintaining the integrity of structures. They also allow water to pass through while retaining soil particles, facilitating proper drainage and preventing clogging.

2.2 Geomembrane

Geomembranes are impermeable sheets or liners made from synthetic materials such as high-density polyethylene (HDPE), polyvinyl chloride (PVC), or ethylene propylene diene terpolymer (EPDM). They are designed to provide a reliable barrier against fluid migration in containment applications. Geomembranes are commonly used in waste containment facilities, pond lining, and water containment structures to prevent the leakage of contaminants into the surrounding environment.

2.3 Geogrid

Geogrids are rigid or flexible grid-like structures made from polymers or metals. They are used primarily for reinforcement purposes in containment applications. Geogrids distribute loads over a wider area, improving the stability and load-bearing capacity of soils. They are often employed in retaining walls, slope stabilization, and road construction to enhance the structural integrity of the containment system.

2.4 Geosynthetic Clay Liners (GCLs)

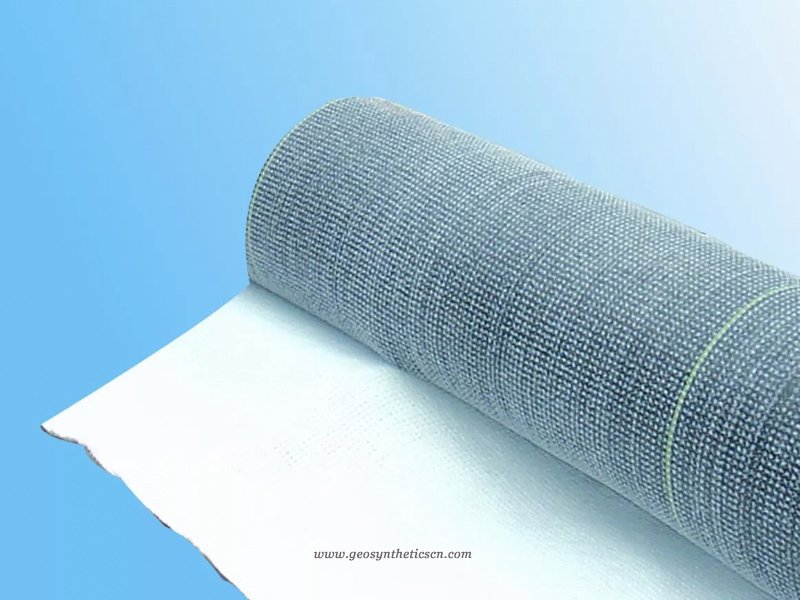

Geosynthetic Clay Liners (GCLs) are another type of geosynthetic material commonly used in containment applications. GCLs are composite materials composed of a layer of bentonite clay encapsulated between two geotextiles or geosynthetic membranes.

The bentonite clay used in GCLs is a highly expandable and low-permeability material. When hydrated, the clay swells to form a waterproof barrier, effectively preventing the migration of liquids or gases. The geotextiles or geosynthetic membranes that encapsulate the clay provide additional structural support and enhance the liner’s mechanical properties.

These three geosynthetics—geotextile, geomembrane, and geogrid—work together or individually to address specific requirements in containment applications. Their selection depends on factors such as the type of containment, the nature of the soil, and the desired performance characteristics. By utilizing these geosynthetics appropriately, engineers and construction professionals can create robust containment systems that meet project specifications and ensure environmental protection.

3. Geotextile

Geotextile are commonly categorized into nonwoven Geotextile and woven Geotextile In which the woven and nonwoven Geotextile have PP and PET Geotextile.

3.1 PP and PET Non woven Geotextile

Polypropylene (PP) non woven geotextiles and Polyester (PET) non woven geotextiles are both types of nonwoven geotextiles used in civil engineering and construction projects.

3.1.1 Material Composition

PP Nonwoven Geotextiles: PP nonwoven geotextiles are made from polypropylene fibers, which are lightweight, chemically inert, and resistant to biological degradation.

PET Nonwoven Geotextiles: PET nonwoven geotextiles are made from polyester fibers, specifically polyethylene terephthalate (PET). Polyester fibers offer high tensile strength, dimensional stability, and resistance to creep and elongation. PET fibers are more resistant to creep under sustained loads compared to PP fibers. It also better in aging properties compared with PP geotextile.

3.1.2 Chemical Resistance

PP Nonwoven Geotextiles: PP geotextiles have good resistance to most chemicals, acids, and alkalis, making them suitable for use in aggressive environments, such as landfills and contaminated sites.

PET Nonwoven Geotextiles: PET geotextiles exhibit excellent chemical resistance to a wide range of acids, alkalis, and organic solvents, making them ideal for applications requiring protection against chemical exposure and degradation.

3.1.3 UV Resistance

PP Nonwoven Geotextiles: PP geotextiles have moderate to high UV resistance, but they may degrade over time when exposed to prolonged sunlight and outdoor weathering. UV stabilizers are often added to PP geotextiles to enhance their resistance to UV degradation.

PET Nonwoven Geotextiles: PET geotextiles have excellent UV resistance and are more resistant to degradation from prolonged exposure to sunlight compared to PP geotextiles. They are suitable for applications requiring long-term outdoor exposure and UV protection.

3.2 PP and PET Woven Geotextile

Woven PP (Polypropylene) geotextiles and woven PET (Polyester) geotextiles are both types of woven geotextiles used in civil engineering and construction projects. While they share some similarities, they also have distinct differences in terms of material properties, performance characteristics, and applications. Here’s a comparison between woven PP geotextiles and woven PET geotextiles:

3.2.1 Strength and Durability

Woven PP Geotextiles: PP geotextiles have high tensile strength and excellent durability, making them suitable for applications requiring reinforcement, separation, and stabilization of soil and aggregate materials. They are commonly used in road construction, erosion control, and landfill engineering projects.

Woven PET Geotextiles: PET geotextiles also have high tensile strength and durability, with superior resistance to creep and elongation compared to PP geotextiles. They are often used in applications where long-term stability and load-bearing capacity are critical, such as retaining walls, embankments, and reinforced slopes.

3.2.2 Chemical Resistance

Woven PP Geotextiles: PP geotextiles have good resistance to most chemicals, acids, and alkalis, making them suitable for use in aggressive environments, such as landfills and contaminated sites.

Woven PET Geotextiles: PET geotextiles exhibit excellent chemical resistance to a wide range of acids, alkalis, and organic solvents, making them ideal for applications requiring protection against chemical exposure and degradation.

3.2.3 UV Resistance

Woven PP Geotextiles: PP geotextiles have moderate to high UV resistance, but they may degrade over time when exposed to prolonged sunlight and outdoor weathering. UV stabilizers are often added to PP geotextiles to enhance their resistance to UV degradation.

Woven PET Geotextiles: PET geotextiles have excellent UV resistance and are more resistant to degradation from prolonged exposure to sunlight compared to PP geotextiles. They are suitable for applications requiring long-term outdoor exposure and UV protection.

3.3 What Are The Geotextile Functions And Applications Of Geotextile

Geotextile is permeable fabrics made from synthetic fibers, such as polypropylene, polyester, or polyethylene. They are used for various functions, including filtration, separation, reinforcement, and drainage. Geotextiles are commonly used in road construction, erosion control, landfill engineering, and slope stabilization.

They are used for various functions, including filtration, separation, reinforcement, and drainage. Geotextiles are further classified based on their primary functions:

3.3.1 Filtration Function of Geotextile

The filtration function of geotextiles is essential in projects where there is a need to control the flow of water while preventing the movement of soil particles. Geotextiles with filtration capabilities are employed in various civil engineering, construction, and environmental projects to protect soil structures, drainage systems, and water bodies from erosion, clogging, and contamination. Here are some common types of projects that often require the filtration function of geotextiles:

Drainage Systems. Geotextiles are used in drainage systems, including French drains, subsurface drainage pipes, and geocomposite drains, to filter out fine particles from infiltrating water while allowing water to pass through. By preventing soil particles from clogging drainage pipes and channels, geotextiles help maintain the efficiency and longevity of drainage systems, reducing the risk of blockages and waterlogging.

Landfill Engineering. Geotextiles are utilized in landfill engineering projects to provide filtration and drainage capabilities in landfill liner and cover systems. Geotextiles prevent soil particles from migrating into drainage layers or leachate collection systems, ensuring the effectiveness of landfill containment and environmental protection measures.

Road Construction. Geotextiles are used in road construction projects to filter out fine particles from subgrade soils, aggregate base materials, and pavement layers. By maintaining the integrity of road foundations and drainage systems, geotextiles help prevent soil erosion, reduce the risk of subsidence, and extend the service life of roads, highways, and airport runways.

Stormwater Management: Geotextiles are employed in stormwater management projects to filter pollutants and sediments from stormwater runoff before it enters receiving waters. Geotextile sediment traps, silt fences, and sedimentation ponds capture suspended solids and pollutants, allowing clean water to be discharged into natural water bodies or infiltration systems.

Wastewater Treatment: Geotextiles are used in wastewater treatment facilities to filter out solids and contaminants from wastewater streams. Geotextile filtration barriers, filter bags, and sedimentation basins remove suspended solids, oils, and greases from wastewater, improving treatment efficiency and reducing environmental pollution.

3.3.2 Separation Function of Geotextile

Geotextile is used to prevent the mixing of dissimilar soil layers, such as separating soil from aggregate in road construction.

3.3.3 Reinforcement Function of Geotextile

Geotextile reinforcement is utilized in various civil engineering and construction projects where the mechanical properties of soil need to be improved to enhance stability, support heavy loads, reduce settlement, prevent erosion, or control ground movement. Some common types of projects that often require the reinforcement function of geotextiles include:

Retaining Walls: Geotextiles are used to reinforce soil behind retaining walls, such as gravity walls, cantilever walls, and reinforced soil slopes. By providing stability and preventing soil erosion, geotextiles help support the weight of retained soil and structures, reducing the risk of slope failure and settlement.

Embankments and Slopes: Geotextiles are employed to stabilize embankments, slopes, and cut slopes in transportation infrastructure projects, such as highways, railways, and waterways. Geotextile reinforcement helps prevent soil erosion, reduce slope instability, and improve overall slope stability, minimizing the risk of landslides and slope failure.

Road Construction: Geotextiles are used in road construction projects to improve the mechanical properties of subgrade soils, stabilize embankments, and reinforce pavement structures. Geotextiles help distribute loads more uniformly, reduce rutting and deformation, and extend the service life of roads, highways, and airport runways.

Foundation Stabilization: Geotextiles are utilized to reinforce weak or compressible soil foundations in building and infrastructure projects. By providing a stable reinforcement layer, geotextiles help distribute loads more uniformly, reduce settlement, and improve the stability and performance of structures built on soft or unstable soils.

Mine Reclamation: Geotextiles are used in mine reclamation projects to stabilize mine slopes, control erosion, and restore disturbed land to its natural condition. Geotextiles help prevent soil erosion, reduce sediment runoff, and facilitate vegetation establishment in post-mining landscapes.

Drainage Geotextiles: Used to provide drainage pathways for water to flow through soils while preventing soil particles from clogging the system.

4. Geomembrane

Geomembranes are synthetic liners or barriers used to control the movement of fluids, gases, and contaminants in various civil engineering, environmental, and industrial applications. These flexible sheets or membranes are manufactured from polymer materials such as high-density polyethylene (HDPE), polyvinyl chloride (PVC), ethylene propylene diene monomer (EPDM), and LLDPE (Linear Low-Density Polyethylene) Geomembrane.

Geomembranes are designed to provide impermeable barriers that prevent the migration of liquids and gases through soil or structures, protecting against leaks, seepage, and contamination. They are used to create barriers for containment, waterproofing, and environmental protection in applications such as landfill liners, pond liners, and secondary containment systems.

4.1 What Are Advantages And Disadvantages of Different Kinds of Geomembrane

Different types of geomembranes, such as HDPE (High-Density Polyethylene), PVC (Polyvinyl Chloride), EPDM (Ethylene Propylene Diene Monomer), and others, offer various advantages and disadvantages depending on their material properties, application requirements, and site conditions. Here’s a general overview of the advantages and disadvantages of these common geomembrane types:

4.1.1 HDPE Geomembrane

Advantages:

Excellent chemical resistance to acids, alkalis, and organic solvents.

High tensile strength and puncture resistance.

Excellent UV resistance and long-term durability.

Flexible and easy to install, with welded seams for watertight connections.

Suitable for a wide range of applications, including landfill liners, pond liners, and containment systems.

Disadvantages:

Susceptible to stress cracking at elevated temperatures.

Limited flexibility at low temperatures, may become brittle.

Not suitable for applications with high temperatures or exposure to certain chemicals.

4.1.2 PVC Geomembrane

Advantages:

Flexible and conformable, suitable for contouring to irregular surfaces.

Excellent resistance to UV degradation and weathering.

Cost-effective compared to other geomembrane materials.

Good chemical resistance to acids, alkalis, and some organic solvents.

Suitable for applications such as pond liners, wastewater containment, and decorative ponds.

Disadvantages:

Lower puncture resistance compared to HDPE.

Susceptible to plasticizer migration, which can affect long-term flexibility.

Not suitable for applications with high temperatures or exposure to hydrocarbons.

4.1.3 EPDM Geomembrane

Advantages:

Excellent flexibility and elongation properties, suitable for irregular surfaces.

Good resistance to UV radiation and weathering.

High tensile strength and puncture resistance.

Good chemical resistance to acids, alkalis, and some solvents.

Suitable for applications such as pond liners, decorative ponds, and rooftop gardens.

Disadvantages:

Higher cost compared to HDPE and PVC.

Limited availability of large panel sizes, may require field seaming.

Vulnerable to damage from sharp objects or abrasion during installation.

4.1.2 LLDPE Geomembrane

Advantages:

Similar properties to HDPE but with improved flexibility and elongation.

Excellent resistance to stress cracking and environmental stress cracking.

Good chemical resistance to a wide range of substances.

Suitable for applications such as landfill liners, containment ponds, and secondary containment systems.

Disadvantages:

May have lower tensile strength compared to HDPE.

Higher cost compared to HDPE.

Requires careful handling during installation to prevent damage.

5. Geogrid

Geogrids are rigid or flexible grid-like structures made from polymer materials, such as polyethylene or polypropylene. They are used primarily for soil reinforcement and stabilization applications, including retaining walls, embankments, and reinforced slopes. Geogrids improve soil strength and distribute loads more evenly, reducing settlement and improving overall stability.

6. Geosynthetic Clay Liners (GCLs)

GCLs are composite materials consisting of a layer of bentonite clay sandwiched between two geotextile or geomembrane layers. They are used for hydraulic barriers and landfill liners due to their high hydraulic conductivity resistance and self-sealing properties when hydrated.

Other types of geosynthetics include geocomposites (combination products that incorporate two or more geosynthetic materials), geocells (three-dimensional cellular confinement systems), and geonets (net-like structures used for drainage and soil reinforcement).

Welcome contact GEOSINCERE Team for any inquiry for above geosynthetics.

7. Conclusion

GEOSINCERE’s commitment to quality is evident through its certifications, including ISO9001, ISO14001, and OHSAS18001. These certifications validate the company’s adherence to international standards for quality management, environmental management, and occupational health and safety.

The range of innovative and high-quality geomembrane liners offered by GEOSINCERE is extensive. It includes smooth HDPE geomembrane liners, textured HDPE geomembranes, composite geomembrane liners, LDPE liners, LLDPE liners, PVC geomembrane liners, HDPE pond liners, LDPE pond liners, PVC pond liners, EPDM liners, and more. These geomembrane liners are designed to excel in various applications, including environmental, civil, and industrial projects.

With GEOSINCERE’s wide range of geomembrane liner options, customers can confidently select the best solution to meet their specific project requirements. We ar dedication to quality, expertise, and comprehensive product offerings makes it a trusted choice for geomembrane liners in environmental, civil, and industrial applications.