The mining industry is the backbone of modern civilization, providing the essential raw materials for everything from infrastructure to technology. However, this critical activity generates a monumental byproduct: tailings. These fine-grained, often chemically complex residues are a significant environmental liability, stored in massive impoundments known as tailings storage facilities (TSFs). The integrity of these facilities is paramount, not just for operational continuity but for environmental protection and public safety. At the heart of modern TSF design lies a seemingly simple yet profoundly critical component: the geomembrane. Selecting the best geomembrane is not a mere procurement decision; it is a fundamental engineering choice with decades-long consequences. This ultimate guide delves into the critical factors, materials, and considerations essential for choosing the best geomembrane for your tailing mine project.

1. Understanding the Hostile Environment of a TSF

A geomembrane in a TSF does not have an easy job. It operates in one of the most demanding environments in civil engineering. The selection process must begin with a thorough understanding of these challenges:

- Chemical Attack: Tailings slurries can be highly acidic or alkaline and often contain residual process chemicals, heavy metals, and salts. The liner must be chemically resistant to maintain its integrity over the long term.

- Ultraviolet (UV) Exposure: During installation and before being covered, the geomembrane is exposed to intense solar radiation, which can degrade certain polymers.

- Temperature Extremes: From scorching heat to freezing cold, materials expand and contract. The liner must have good flexibility and thermal stability to withstand these cycles without becoming brittle or losing strength.

- Stress and Strain: TSFs are dynamic structures. Subsidence, settling of the underlying subgrade, and the immense hydraulic pressure from the fluid tailings subject the liner to significant multidirectional stresses. It must have high tensile strength and puncture resistance.

- Installation Stresses: The sheer scale of a TSF means seams run for kilometers. The quality of these seams, achieved through welding or bonding, is a critical point of potential failure.

2. The Contenders: A Breakdown of Geomembrane Materials

No single geomembrane material is perfect for every application. The choice depends on a careful balance of the factors above. The primary materials used in tailing mines are:

2.1 Best Geomembrane – High-Density Polyethylene (HDPE)

- Description: The undisputed workhorse of the mining industry. HDPE is a stiff, high-strength, durable polymer known for its exceptional chemical resistance.

Pros:

- Superior Chemical Resistance: Highly inert, making it excellent for a wide range of aggressive leachates, including strong acids and alkalis.

- High Tensile Strength: Excellent resistance to stress cracking under long-term load.

- Proven Durability: With a long track record, its performance and lifespan (60+ years) are well-understood.

Cons:

- Low Flexibility: More rigid than other options, making it less ideal for uneven subgrades or projects with potential for significant differential settlement.

- Seaming Challenges: Requires expert fusion welding; seams can be brittle and are sensitive to poor workmanship.

- Thermal Expansion: Has a high coefficient of thermal expansion, requiring careful design to manage wrinkles.

2.2 Best Geomembrane – Linear Low-Density Polyethylene (LLDPE)

- Description: A more flexible and forgiving cousin of HDPE.

Pros:

- Excellent Flexibility and Elongation: Conforms well to uneven subgrades and can accommodate more movement and settlement without damage.

- Good Stress Crack Resistance: Superior to HDPE in many flexible formulations.

- Easier Seaming: Softer nature can make field seaming slightly more forgiving.

Cons:

- Lower Chemical Resistance: Generally less chemically resistant than HDPE, particularly to hydrocarbons and some organic solvents.

- Lower Tensile Strength: Not as strong as HDPE, making it more susceptible to puncture under high loads.

2.3 Best Geomembrane – Polyvinyl Chloride (PVC)

- Description: A very flexible material that is often reinforced with polyester scrim for added strength.

Pros:

- High Flexibility: Extremely conformable and easy to install on complex shapes.

- Ease of Seaming: Seams are made using solvent or adhesive systems, which can be simpler than thermal welding.

Cons:

- Poor UV Resistance: Requires additives for UV stabilization and must be covered quickly.

- Plasticizer Migration: The plasticizers that give PVC its flexibility can leach out over time, especially when exposed to certain chemicals, causing the material to become brittle and fail.

Generally not the first choice for primary containment in modern, high-risk tailing facilities due to long-term durability concerns.

2.4 Best Geomembrane – Reinforced Polypropylene (RPP)

- Description: A strong contender that combines flexibility with high chemical and UV resistance.

Pros:

- Excellent Chemical Resistance: On par with or exceeding HDPE for many chemicals.

- Superior UV Stability: The most UV-resistant of the common geomembranes, ideal for extended exposed applications.

- Flexibility: More flexible than HDPE while maintaining high tensile strength due to its reinforcement.

Cons:

- Cost: Often more expensive than HDPE or LLDPE.

- Seaming: Requires specialized dual-track thermal welding equipment.

3. Key Selection Criteria: Best Geomembrane Decision-Making Framework

Choosing the best geomembrane involves a systematic evaluation:

- Compatibility Testing: This is non-negotiable. Laboratory testing (e.g., ASTM D5747) where the candidate geomembrane is immersed in the actual site-specific tailings leachate under elevated temperatures is essential. The test evaluates changes in weight, dimensions, tensile properties, and flexibility. The goal is to select a material that shows minimal degradation.

Physical and Mechanical Properties:

- Tensile Strength and Elongation: Does the project require the high strength of HDPE or the high elongation of LLDPE/RPP to handle deformation?

- Puncture Resistance: What is the nature of the subgrade? A smooth geomembrane may require a protective geotextile if placed on a rocky subgrade.

- Stress Crack Resistance: Critical for HDPE formulations. A notched constant tensile load (NCTL) test (ASTM D5397) should be specified to ensure long-term performance.

4. Site-Specific Conditions:

- Subgrade Quality: A very uneven subgrade favors more flexible materials like LLDPE or RPP.

- Climate: Projects in areas with high temperature swings must account for thermal expansion. High UV exposure sites favor HDPE or RPP.

- Seismic Activity: In earthquake-prone zones, a geomembrane with high ductility and elongation-at-break (like LLDPE) is crucial to absorb seismic energy without rupturing.

5. Installation and Quality Assurance (QA):

The best material is useless if poorly installed. Consider the availability of experienced installation crews for your chosen material (e.g., HDPE welders require specific certification).A rigorous QA/QC program is mandatory. This includes destructive and non-destructive testing of field seams (e.g., peel tests, air pressure tests) on a daily basis.

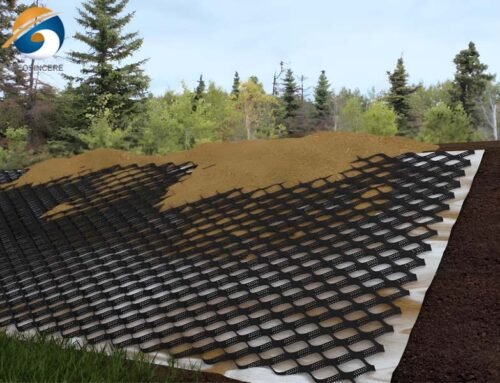

6. Beyond the Material: The System Approach

A geomembrane is only one part of a composite liner system. It must be integrated with:

- A low-permeability clay layer (compacted or GCL) to provide a secondary barrier.

- Geonets or drainage composites to manage leakage detection and seepage.

- Protective geotextiles to prevent puncture.

- The interaction between all these components is critical to the system’s overall performance.

7.Conclusion

Selecting the best geomembrane for a tailing mine is a complex, multi-disciplinary process that blends geotechnical engineering, chemistry, and materials science. There is no universal “best” answer—only the “most appropriate” solution for a specific set of conditions.While HDPE remains the default choice for its proven chemical resistance and strength, LLDPE offers superior flexibility for challenging subgrades, and RPP presents a high-performance option for harsh exposed conditions. The decision must be grounded in rigorous compatibility testing and a clear-eyed assessment of the site’s physical and environmental risks.

Ultimately, this choice is about responsibility. It is about ensuring that the temporary wealth extracted from the earth does not come at the cost of permanent environmental damage. By making an informed, scientifically-grounded selection, mining operators invest not just in a product, but in the long-term safety of their operation, the health of the surrounding environment, and the well-being of future generations. The GEOSINCERE geomembrane is the silent guardian of the TSF; choosing it wisely is a testament to sustainable and ethical engineering.