Are you interested in learning all about Best HDPE geomembranes? Look no further! In this article, we’ll take a deep dive into all things HDPE geomembranes and give you all the information you need.Whether you’re a construction professional or just curious, this guide will give you the knowledge you need.

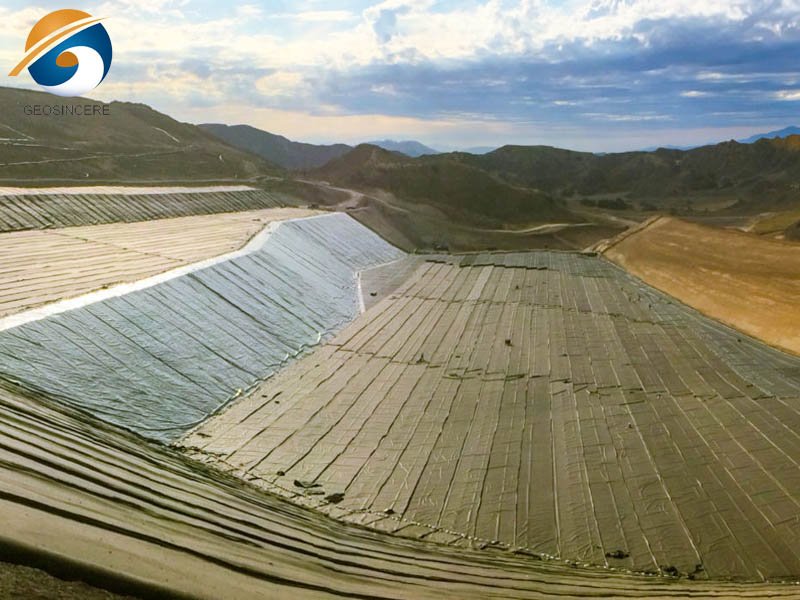

HDPE (High-Density Polyethylene) geomembranes are a versatile and effective solution used across a wide range of industries, including civil engineering, agriculture, and mining. Providing unparalleled protection against leaks and contamination, they are an integral component in containment, lining, and environmental protection projects.

In this comprehensive guide, we’ll take a deep dive into the characteristics, benefits, applications, and installation methods of GEOSINCERE HDPE geomembranes. We’ll explain complex terminology and provide practical advice to help you make informed decisions for your projects. If you’re ready to become an HDPE geomembrane expert,

1. What Is Best HDPE geomembrane:

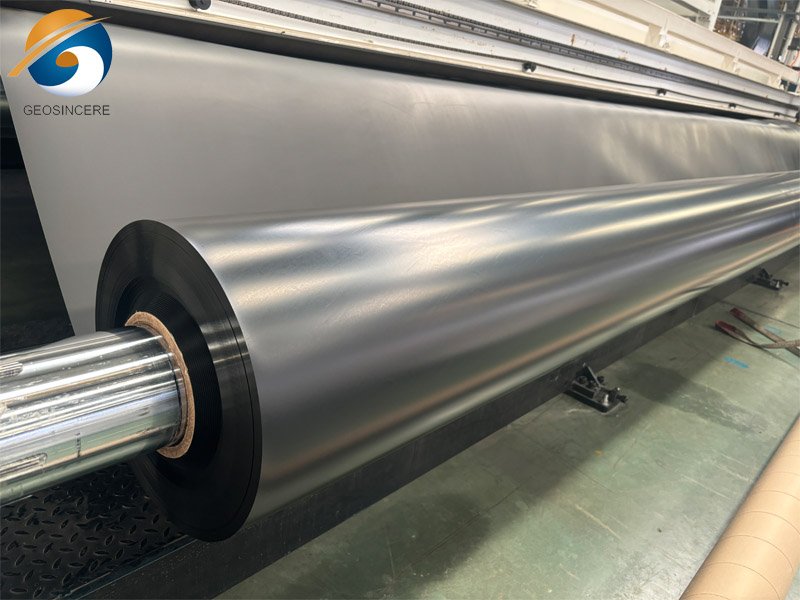

High-density polyethylene (HDPE) geomembranes are synthetic liners made from high-density polyethylene, a thermoplastic polymer known for its exceptional strength and durability. Learn more about its properties and applications. It is made through an extrusion process, where the polymer is melted and then extruded into a thin sheet. The resulting geomembrane is resistant to chemicals, UV radiation, and mechanical stress, making it a reliable choice for a variety of applications.

One of the main properties of HDPE geomembrane is its impermeability. It acts as a barrier, preventing the migration of liquids, gases, and pollutants. Learn more about its applications across industries. This makes it ideal for projects involving containment, such as landfills, ponds, reservoirs, and wastewater treatment plants. HDPE geomembranes are also used in lining applications such as canals, tunnels, and underground tanks, where preventing leaks is critical.

The thickness of HDPE geomembranes varies depending on the specific application and requirements. Geomembranes are available in a variety of thicknesses, usually measured in mils (thousandths of an inch) or millimeters. Thicker geomembranes have a higher resistance to punctures and are suitable for more demanding environments.

2. What are Best HDPE Geomembrane Features?

2.1 Best HDPE Geomembrane – High-Density Polyethylene (HDPE)

HDPE geomembrane is made from high-density polyethylene, a thermoplastic polymer known for its strength and durability. This material exhibits excellent chemical resistance, UV resistance, and flexibility, making it suitable for a wide range of applications. With its high tear resistance and puncture resistance, HDPE geomembrane provides long-term protection against leaks and contamination.

2.2 Best HDPE Geomembrane – Impermeability

One of the primary purposes of HDPE geomembrane is to provide an impermeable barrier. Due to its dense molecular structure, HDPE geomembrane offers exceptional resistance to liquid and gas permeation. It effectively prevents the migration of pollutants, chemicals, and liquids, thereby protecting the environment and underlying structures.

2.3 Best HDPE Geomembrane – Flexibility and Adaptability

HDPE geomembrane is highly flexible and can adapt to irregular surfaces and contours. This property makes it suitable for lining applications in ponds, reservoirs, and canals, where a seamless barrier is required. Its flexibility also allows it to withstand ground movements and settle without compromising its integrity.

2.4 Best HDPE Geomembrane – UV Stability

Exposure to sunlight can degrade the performance of geomembrane materials over time. However, HDPE geomembrane is UV stabilized to withstand extended exposure to sunlight without significant degradation. This UV stability ensures its longevity and performance in outdoor applications.

2.5 Best HDPE Geomembrane – Chemical Resistance

HDPE geomembrane demonstrates excellent resistance to a wide range of chemicals, including acids, alkalis, and organic solvents. This resistance makes it a reliable choice for projects involving chemical containment and waste management. HDPE geomembrane can protect the underlying soil and groundwater from chemical contamination.

3. How to Choose the Perfect Best HDPE Geomembrane?

Choosing the ideal HDPE geomembrane is more than a technical decision; it’s a strategic investment in the longevity and success of your project. With so many options to choose from, it’s critical to understand the nuances of thickness, tensile strength, cost, chemical resistance, UV resistance, and installation requirements. Here’s how to make your decision:

3.1 HDPE Geomembrane Thickness (0.2mm – 3.0mm):The Foundation of Durability

HDPE geomembranes are available in a variety of thicknesses, typically ranging from 0.5mm to 3.0mm. Thicker membranes (1.5mm and above) offer better puncture resistance and durability, making them ideal for harsh environments like mining or landfills. Thinner liners (0.75mm – 1.0mm) may be suitable for less demanding uses, such as ponds.

3.2 HDPE Geomembrane Liner Tensile Strength:

The Cornerstone of Performance for applications with sharp substrates (e.g., rocky terrain), a high puncture resistance geomembrane (≥ 500 N) is recommended. Tensile strength (ASTM D6693) should also be evaluated to ensure stability under stress.

3.3 HDPE Geomembrane Liner Cost: Balancing Budget and Performance

The cost of HDPE liners depends on thickness, tensile strength, and additional features such as UV resistance or chemical additives.

Here’s how to strike the best balance:

- Affordable Choice: Thin, low-tensile liners are economical for small, low-stress projects.

- Mid-Range Liners: Medium thickness and tensile strength provide a good balance for most industrial and agricultural applications.

- Premium Liners: High thickness and tensile strength mean higher costs, but their durability and longevity are unmatched.

3.4 UV Resistant:Protects against the Sun

For projects exposed to intense sunlight, standard HDPE liners can degrade over time. UV-resistant liners feature advanced stabilizers that effectively protect against UV radiation, ensuring the liner remains intact for decades.

- Durability: UV-resistant liners withstand years of direct sunlight without losing their structural integrity.

- Cost Effectiveness: Reduces the need for frequent replacement or repairs, saving time and money.

- Applications: Ideal for outdoor reservoirs, agricultural ponds, and landfill covers in sunny climates.

- Pro Tip: Pair UV resistance with thicker liners for optimal durability in sunny areas.

3.5 Chemical Additives:Protects Against the Strongest Substances

In environments where harsh chemicals are present, standard liners may not suffice. Chemical additives can be infused into HDPE geomembrane liners to create a strong barrier against acids, bases, solvents, and other corrosive substances.

Choose a Reliable Supplier to Quote Price for You :

GEOSINCERE has been keeping on investing in technological innovation, manufacturing facilities improvement and turnkey engineering abilities. We have invested 10 million dollars into our manufacturing factory which is equipped with state-of-the-art automatic production lines to manufacture high quality HDPE geomembranes and other geosynthetics with optimized processes. Our extensive lines of geosynthetics products are well known for their ensured quality, high performance, excellent durability and best cost effectiveness.

GEOSINCERE brand HDPE geomembranes and other geosynthetics products and solutions can meet your requirements by our solid technologies, innovative engineering solutions and excellent customer services. GEOSINCERE always tries our best to solve the most complex civil, mining and environmental challenges with our innovative and high performance geosynthetic products. Quality assurance, factory price and fast delivery time are our competitive advantages.