Landfills represent a critical, though often unseen, component of modern waste management. Their primary function – safely containing vast quantities of waste to protect the surrounding environment, particularly groundwater and soil – hinges on one crucial element: the liner system. While often referred to colloquially as “pond liner,” in landfill engineering, the material of choice is overwhelmingly High-Density Polyethylene (HDPE) Geomembrane. This isn’t just a simple sheet; it’s a highly engineered barrier designed for extreme longevity and performance. Let’s delve into the Top 7 Features Of HDPE Pond Liner For Landfills applications.

1. HDPE Pond Liner For Landfills – Unparalleled Chemical Resistance

- The Challenge: Landfill leachate is a toxic brew. As water percolates through decomposing waste, it picks up a staggering array of contaminants: acids, alkalis, solvents, heavy metals, salts, organic compounds, and biological agents. A liner must resist degradation from this aggressive chemical soup for decades.

- HDPE’s Superpower:HDPE possesses exceptional inertness. Its non-polar molecular structure makes it highly resistant to a vast spectrum of chemicals commonly found in leachate. Unlike some other plastics, it doesn’t swell, dissolve, or significantly weaken when exposed to harsh acids, bases, alcohols, or oxidizing agents. This resistance is fundamental to preventing liner failure and subsequent contamination of the subsoil and groundwater. Testing against standardized chemical suites (like EPA Method 9090) consistently demonstrates HDPE’s superior performance.

2. HDPE Pond Liner For Landfills – Exceptional Durability & Longevity

2.1 The Challenge:

Landfills are long-term containment facilities, often requiring environmental protection for 30, 50, 100 years, or more, even after closure. The liner must withstand constant stress, environmental exposure, and potential settlement without significant degradation.

2.2 HDPE’s Superpower:

HDPE geomembranes are designed for extreme longevity. Key factors contributing to this:

- UV Resistance:Formulated with high-quality carbon black (typically 2-3%), HDPE liners effectively resist degradation from sunlight (UV radiation), crucial during installation and before final cover placement.

- Stress Crack Resistance (SCR):High-quality HDPE formulations possess excellent SCR, measured by standardized tests like the Notched Constant Tensile Load Test (NCTL). This prevents the formation and propagation of cracks under long-term stress, a critical failure mode in geomembranes.

- Biological Resistance:HDPE is impervious to rot, fungal growth, and rodent/insect attack, common threats to organic-based materials.

Material Integrity: Manufactured under strict quality control (ASTM, GRI standards), HDPE geomembranes are homogenous and free from defects that could become failure points.

3. HDPE Pond Liner For Landfills – Very Low Permeability

- The Challenge: The core function of a landfill liner is to prevent the migration of leachate out of the waste containment area. Even minuscule amounts of leakage over vast areas and long timescales can lead to significant environmental damage.

- HDPE’s Superpower: HDPE geomembranes have an exceptionally low permeability coefficient, typically on the order of 1 x 10<sup>-13</sup> cm/s or lower. This means water vapor transmission through the intact material itself is negligible. While seams and penetrations require meticulous attention, the intrinsic impermeability of the HDPE sheet itself is orders of magnitude better than compacted clay liners alone. It acts as a nearly impervious hydraulic barrier.

4. HDPE Pond Liner For Landfills – High Strength & Puncture Resistance

4.1 The Challenge:

Landfill construction and operation are rough environments. Liner installation involves heavy equipment moving over the surface. Waste placement exerts significant loads. Sharp objects within the waste stream pose puncture risks. The liner must withstand these physical stresses.

4.2 HDPE’s Superpower:

HDPE geomembranes offer high tensile strength, tear resistance, and puncture resistance. Key properties include:

- Tensile Strength:Measured in both machine and cross-machine directions, HDPE has high yield and break strength.

- Puncture Resistance:Tests like ASTM D4833/D4883 simulate the force required for a probe or stone to puncture the liner. Thicker HDPE liners (common in landfills) offer exceptional resistance.

- Tear Resistance:ASTM D1004 (Trouser Tear) and D5884 (Constant-Rate-of-Traverse Tear) measure resistance to tearing forces. HDPE performs well.

- Impact Resistance:The material can absorb significant impact energy without failing.

5. HDPE Pond Liner For Landfills – Proven Seam Integrity & Weldability

- The Challenge: Landfill liners cover acres, requiring multiple panels to be joined seamlessly. The integrity of these seams is paramount – a weak seam is a failure point. The joining method must be reliable, field-proven, and verifiable.

- HDPE’s Superpower: HDPE is ideally suited for thermal fusion welding, the industry standard for creating monolithic, watertight seams. Methods include:

- Dual Hot Wedge Welding: Creates two parallel weld beads with an air channel for nondestructive testing (NDT).

- Extrusion Welding: Used for complex details, patches, and repairs.

- Testability: Seams are rigorously tested using both destructive (peel, shear tests) and highly reliable nondestructive methods (e.g., air pressure testing in the channel, vacuum testing). This allows for near-100% verification of seam integrity across the entire liner.

6. HDPE Pond Liner For Landfills – Flexibility & Conformance

- The Challenge: The ground beneath a landfill liner (subgrade) is rarely perfectly smooth or rigid. It may settle unevenly over time. The liner needs to conform to the underlying surface without bridging voids or developing excessive stress points that could lead to tears or punctures.

- HDPE’s Superpower: While possessing high strength, HDPE geomembranes have sufficient flexibility to conform well to prepared subgrades. They can accommodate minor differential settlement without immediate failure. This flexibility is crucial during installation, as the liner must drape over contours and into sumps without creasing or stressing excessively. Proper preparation of a smooth, compacted subgrade is essential to maximize this benefit.

7. HDPE Pond Liner For Landfills – Cost-Effectiveness Over the Long Term

7.1 The Challenge:

Landfill construction is a major capital investment. While initial liner cost is a factor, the true cost includes installation, long-term performance, environmental liability protection, and post-closure care. A cheaper liner that fails prematurely is catastrophically expensive.

7.2 HDPE’s Superpower:

HDPE geomembranes offer outstanding lifecycle value:

7.3 Durability Pays Off:

Their proven longevity (properly installed and protected) means they function effectively for the entire required containment period, avoiding the astronomical costs of remediation due to liner failure and groundwater contamination.

- Efficient Installation:Standardized installation and welding techniques, while requiring skilled crews, are well-established and efficient for large-scale projects.

- Material Efficiency: Compared to thick compacted clay layers (CCLs) required to achieve low permeability alone, HDPE provides a superior barrier in a much thinner profile, often reducing earthwork requirements. Modern composite liner systems (HDPE + CCL) leverage the strengths of both.

- Risk Mitigation: The reliability of HDPE significantly reduces the long-term financial and environmental risks associated with landfill operation and closure.

8. How to Properly Install HDPE Pond Liner For Landfills

While HDPE possesses these exceptional features, its performance is only guaranteed with:

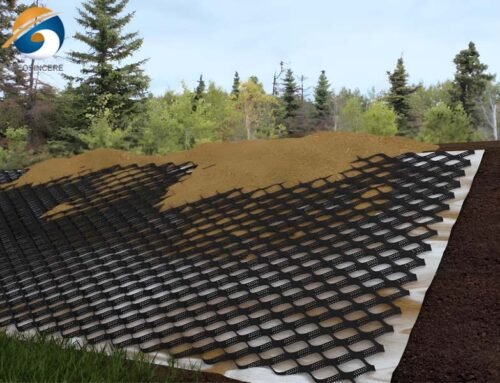

- Meticulous Subgrade Preparation:A smooth, compacted, stable, and debris-free foundation is non-negotiable. Geotextile protection layers are often used.

- Expert Installation & Welding:Certified installers using calibrated equipment and following strict quality assurance/quality control (QA/QC) procedures are essential. Seam testing is critical.

- Robust Protection Layers:Above the liner, a drainage layer (leachate collection system) and protective cover (geotextile, soil) shield it from damage during waste placement and compaction.

- Quality Material:Sourcing HDPE geomembrane from reputable manufacturers adhering to international standards (e.g., GRI GM13, ASTM) is fundamental.

9. Conclusion

HDPE geomembrane is far more than just a “pond liner” in the landfill context. It’s a sophisticated, high-performance engineered barrier whose top features – unmatched chemical resistance, exceptional durability and longevity, near-zero permeability, high strength, reliable seam integrity, flexibility, and long-term cost-effectiveness – make it the indispensable shield protecting our environment from the complex challenges of waste containment. Its proven track record in landfills worldwide underscores its vital role in responsible waste management. When the integrity of groundwater and soil for generations to come is at stake, the robust properties of HDPE provide the essential foundation for safe and secure landfill design and operation. Investing in high-quality HDPE liner and its proper installation is an investment in long-term environmental protection. For more inforation, kindly contact GEOSINCERE.