In modern transportation infrastructure, the driveway is one of the core functional components of the entire road system. Whether it’s a rural path, residential neighborhood, industrial park, or temporary construction access, the stability and load-bearing capacity of the driveway directly affect the safety and comfort of vehicle traffic. As the demands for subgrade stability and sustainable construction increase, traditional road structure solutions are gradually revealing their limitations. At this point, Geocell for Driveway technology has emerged as an efficient, eco-friendly ground reinforcement solution, gaining traction among designers and contractors.

Faced with a wide variety of Geocell products, how can procurement managers and engineering technicians choose the right one for their driveway project? This article provides an in-depth analysis from multiple dimensions to help you make informed decisions and avoid costly mistakes.

1. What Is Geocell and Why Is It Suitable for Driveways?

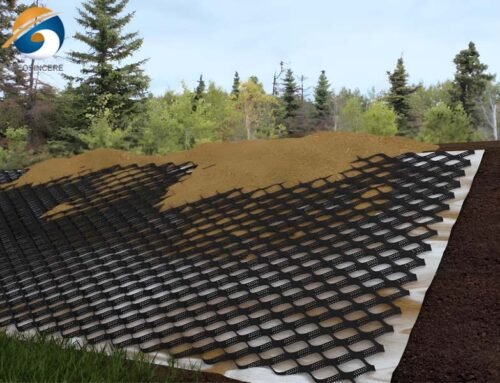

Geocell is a honeycomb-like polymer structure, typically made of high-density polyethylene (HDPE). During installation, it is expanded to form a cellular network which is then filled with soil, gravel, sand, or other materials to enhance lateral confinement, vertical support, and anti-erosion capabilities.

Why is Geocell suitable for driveway?

- Increased Load-Bearing Capacity: The 3D structure restricts lateral movement of infill, evenly dispersing wheel loads and improving foundation strength.

- Minimized Rutting and Settlement: Unlike traditional gravel pavements, Geocell helps reduce uneven settlement and rutting caused by water or heavy traffic.

- Adaptability to Various Soil Conditions: Effective on soft soils, sandy ground, mountainous terrains, and more.

- Quick Installation & Reusability: Ideal for temporary access roads; can be dismantled and reused.

- Eco-Friendly: Manufactured from recyclable polymer materials, enabling green and compliant construction.

2. Key Considerations Before Choosing a Geocell for Driveway

2.1 Geocell for Driveway – Subgrade Soil Conditions

If the driveway is built on soft soil, sludge, or expansive clay, high-strength Geocells with superior weld peel strength are recommended to prevent structural tearing.On gravel beds or hard soils, moderate-thickness and mid-strength products are usually sufficient.

Recommendation: For soft soils, choose HDPE Geocells with a thickness ≥1.5mm and weld peel strength ≥14N.

2.2 Geocell for Driveway – Load Class and Traffic Type

- Light-Duty Driveways: Used by pedestrians, bicycles, or small vehicles. Low strength requirements.

- Medium-Duty Driveways: Residential areas or industrial transport lanes. Require moderate to high strength.

- Heavy-Duty Driveways: Construction sites, mining roads, military routes. Require thick Geocells and gravel infill.

| Driveway Type | Recommended Cell Height | Recommended Thickness | Weld Strength |

| Light | 50mm | 1.0mm | ≥10N |

| Medium | 75mm | 1.2mm | ≥12N |

| Heavy | 100–150mm | 1.5–1.8mm | ≥14N |

2.3 Geocell for Driveway – Availability of Fill Materials

Geocells are compatible with various infill materials:

- Compacted soil

- Crushed stone

- Sand/gravel

- Recycled aggregates

The type and particle size of locally available materials directly influence Geocell height selection. For instance, coarse gravel is best paired with cells ≥100mm tall for better interlock and support.

2.4 Geocell for Driveway – Slope and Drainage Conditions

For sloped driveways or rainy regions, choose Geocells with enhanced erosion resistance, supplemented with nonwoven fabric and proper drainage layers.

3. Key Selection Criteria for Geocell for Driveway

3.1 Geocell for Driveway – Material Type

The Geocell material determines its durability and application scope. Common options:

- HDPE (High-Density Polyethylene): UV-resistant and corrosion-proof. Ideal for outdoor, long-term applications.

- PP (Polypropylene): Excellent flexibility. Suitable for regions with large temperature variations.

- PET (Polyester): High tensile strength. Suitable for heavy-load environments.

- Recommendation: Use HDPE for residential driveways; opt for PET or reinforced HDPE for industrial/heavy-duty use.

3.2 Geocell for Driveway – Cell Height and Size

- Height: Typically ranges from 50mm to 300mm. Taller cells provide better load distribution but increase cost.

- Cell Dimensions: Smaller cells (e.g., 200mm x 200mm) suit fine aggregates; larger cells (e.g., 400mm x 400mm) for coarse materials.

Recommendation:

- Use 100–150mm height for light-duty driveways.

- Use 200mm+ for heavy-duty applications.

- Smaller cells offer better confinement and are ideal for heavy traffic.

3.3 Geocell for Driveway – Weld Peel Strength

A measure of connection stability. For high-traffic or construction scenarios, use Geocells with weld peel strength ≥14N.

3.4 Geocell for Driveway – Environmental Compatibility

Consider local climate conditions:

- Cold Regions: Use low-temperature-resistant materials (e.g., PP).

- Hot Regions: Use UV-resistant HDPE.

- High-Humidity or Chemically Aggressive Areas: Use coated or anti-corrosive Geocell types.

3.5 Geocell for Driveway – Infill Compatibility

Geocells must match the chosen fill type:

- Crushed Stone: Offers excellent drainage; widely applicable.

- Concrete: Used for high-strength demands; more expensive.

4. Installation Steps for Geocell Driveways

4.1 Site Preparation

- Clear debris and remove weak soil.

- Compact the base and ensure level grading.

4.2 Geocell Deployment

- Expand and anchor cells using stakes.

- Connect adjacent cells with specialized clips.

4.3 Infill Placement

- Fill in layers and compact each to the design level.

- Avoid over-compaction that may deform the cells.

4.4 Surface Finishing

- Apply asphalt or concrete if needed.

- For temporary roads, compacted gravel is sufficient.

5. Common Issues and Solutions

When improperly installed or mismatched with the application, Geocells may cause performance problems. Below are typical issues and practical remedies.

5.1 Cell Deformation or Displacement

- Symptoms: Misaligned boundaries, bulging or shifting.

- Causes:

Poor layer-wise compaction.

Insufficient anchor points or depth.

No physical restraint during installation.

- Solutions:

Increase anchor density; compact each layer before adding the next.

Use staggered layout and pre-tensioning.

Add perimeter reinforcement or curbs.

5.2 Infill Material Loss

- Symptoms: Fine materials wash away, causing voids or loose structure.

- Causes:

Cell size too large for fine particles.

Permeable subgrade without a geotextile layer.

No drainage system, leading to water erosion.

- Solutions:

Match cell size to fill particle size (e.g., 330mm for fine aggregates).

Use nonwoven geotextile as a separation layer.

Install drainage ditches or French drains.

Compact immediately after filling.

5.3 Long-Term Settlement

- Symptoms: Mid-lane or edge depressions, rutting.

- Causes:Inadequate base compaction.Improper fill moisture content.Poor load dispersion by cell structure.

- Solutions:Conduct geotechnical tests pre-construction.Use gravel base + Geocell reinforcement on soft ground.Choose high-strength HDPE Geocells (weld strength ≥14N).Monitor and refill if settlement is detected early.

5.4 Cell Tearing or Rupture

- Symptoms: Cell failure under extreme conditions.

- Causes:Use of recycled materials with poor properties.Weak weld seams.Thin walls with low pressure resistance.

- Solutions:Use virgin HDPE with CE/ISO certification.For heavy loads, use ≥1.5mm thick cells, weld strength ≥14N.For hot climates, choose UV-stabilized products.Control equipment load during compaction.

5.5 Slow Construction Progress

- Symptoms: Delayed installation, missed deadlines.

- Causes:Inexperienced workers.Lack of deployment tools.Poor site preparation and coordination.

- Solutions:Provide standard videos and installation guides.Use tensioning tools and manual expanders.Pre-mark site sections for modular work.Pre-expand Geocell modules for faster deployment.

6. What GEOSINO Can Offer for Your Driveway Project

As a professional Geocell manufacturer and exporter from China, GEOSINO offers the following advantages:

Export experience to 96 countries, serving mining, highways, agriculture, and defense sectors;

In-house raw material production with 100% virgin HDPE, ensuring quality and cost control;

Complete lab testing system with CE, ISO, SGS certifications available;

Full technical support from design to installation;

Fast response and delivery within 7 days, with global logistics coverage.

7. Conclusion: Choose the Right Geocell for Safer, More Durable Driveways

Driveway stability isn’t just a foundation concern—it’s critical for long-term, sustainable project performance. The right Geocell can reduce maintenance costs, improve vehicle operations, and extend road life.

If you’re seeking suitable Geocell products for your project, feel free to contact the GEOSINCERE international sales team. We will provide customized solutions and quotations based on your local soil conditions and technical requirements.