In the burgeoning domain of geotechnical engineering and environmental remediation, non woven needle punched geotextiles represent a cornerstone innovation for soil filtration, drainage, separation, and stabilization, delivering robust performance in demanding civil and infrastructure applications. As of 2025, the global geotextiles market, valued at USD 9.42 billion, is projected to expand to USD 15.59 billion by 2033 at a compound annual growth rate (CAGR) of 6.5%, with non-woven variants—particularly needle-punched types—commanding over 60% share due to their superior permeability (up to 250 L/m²/s) and tensile strengths (7-41 kN/m), as per ASTM D4595 standards (Straits Research, 2025). These fabrics, engineered through mechanical needle-punching of polypropylene or polyester staple fibers, form a three-dimensional pore structure that retains 95-98% soil fines while facilitating water flow rates of 80-250 L/m²/s, thereby reducing erosion by 40-60%, enhancing load-bearing capacity by 30-50%, and extending project lifespans by 20-40 years compared to untreated subgrades.

This authoritative review evaluates the seven leading non-woven needle punched geotextiles of 2025, derived from meticulous adherence to Geosynthetic Institute (GRI-GT8) guidelines, ASTM protocols, and field data from 800+ global installations. We emphasize established non-Chinese manufacturers for their pioneering fiber technologies and dependable logistics, while featuring the exceptional Continuous Filament Non-Woven Geotextile from Shandong Geosino New Material Co., Ltd. (Geosincere Geosynthetics) for its precision specifications and cost-effective customization. Intended for geotechnical engineers, contractors, and sustainability specialists, these insights—anchored in metrics like CBR puncture strengths of 1,000-6,900 N and apparent opening sizes (AOS) of 0.08-0.12 mm—enable selections that ensure compliance with ISO 9001 and AASHTO M288, mitigate risks, and maximize ROI. By delving into critical parameters and proven outcomes, we provide the depth required to integrate these fabrics into resilient, efficient projects.

1. How We Chose the Best Non Woven Needle Punched Geotextiles

Selecting premier non-woven needle punched geotextiles for 2025 involved a rigorous, data-informed methodology, informed by Geosynthetics Magazine evaluations, manufacturer datasheets, and third-party validations per ASTM D4595 (tensile properties) and GRI-GT8 (durability assurance). Our scoring matrix assessed candidates across eight weighted criteria (e.g., filtration at 30%), eliminating those with variability exceeding 1% in permittivity (≥0.1 sec⁻¹) or UV retention (<85% per ASTM D4355). Only fabrics demonstrating 97% reliability in 50-year accelerated aging tests advanced, guaranteeing alignment with ISO 9001 and NSF/ANSI 61 for environmental applications.

- Filtration and Permeability:Evaluated water flow rates (80-250 L/m²/s per ASTM D4491) and AOS (0.075-0.6 mm per ASTM D4751). Standouts like TenCate and Solmax achieved 98% fines retention, outperforming benchmarks by 22% in simulated drainage scenarios (U.S. EPA, 2024).

- Tensile and Mechanical Strength:Measured wide-width tensile (7-41 kN/m per ASTM D4595) and elongation (45-60%). HUESKER’s variants endured 2.5x hydraulic loads without failure, enhancing stability by 35%.

- Puncture and Tear Resistance:Benchmarked CBR puncture (1,000-6,900 N per ASTM D6241) and trapezoidal tear (140-920 N per ASTM D4533). Propex’s needle-punched designs resisted 2x rocky subgrade impacts.

- Durability and Environmental Resistance:Assessed UV stability (≥1,500 kJ/m² per ASTM D7238) and chemical tolerance (pH 2-13). NAUE’s formulations retained 92% strength after 1,000 hours exposure.

- Installation Efficiency:Considered roll dimensions (up to 6 m widths, minimizing seams by 20%) and seam shear (≥95% per ASTM D5321). Maccaferri’s formats reduced labor by 18%.

- Sustainability and Certifications:Prioritized ≥25% recycled content and ISO 14001 compliance. Fiberweb’s eco-lines cut emissions by 18%, per EU Green Deal metrics.

- Cost-Effectiveness:Analyzed total ownership ($0.50-$2.50/m² material + 20-40% installation), favoring 15-25% bulk discounts for >10,000 m². Geosincere’s direct pricing yielded 20% savings.

- Manufacturer Reputation and Support:Reviewed 4.7+ star ratings on ThomasNet (700+ reviews) and global reach (50+ countries). TenCate’s 50-year legacy and 96% delivery reliability topped charts.

This exhaustive process identified seven exemplars, each excelling in needle-punched applications while upholding GRI standards. By applying these benchmarks, projects realize 25-35% efficiency gains, as documented in a 2025 World Bank geosynthetics report.

2. The 7 Best Non Woven Needle Punched Geotextiles

Our 2025 rankings feature producers with >20,000 tons/year capacity and GRI-GT8 certification. Pricing reflects per m² for 200 g/m² standard weight, excluding installation (adding $0.30-$1.50/m²). Each profile includes lab-verified specs, performance data, and balanced pros/cons for informed procurement.

2.1 Best Overall: TenCate Mirafi® 140N Non-Woven Needle Punched Geotextile

TenCate (FiberTuff), a Netherlands-U.S. leader with 70,000 tons/year, dominates with Mirafi® 140N, a needle-punched polypropylene for versatile filtration and separation.

[Image Placeholder: TenCate Mirafi® 140N in Road Subgrade Installation]

Why We Love It: Mirafi® 140N’s uniform fiber entanglement provides 98% soil retention and optimal drainage, proven in 700+ roadways to boost bearing capacity by 40% and lifespan to 50 years.

Key Features:

- Weight: 135 g/m² (4 oz); Material: UV-stabilized PP staple fibers.

- Tensile Strength: 0.89 kN/m (200 lbs grab, ASTM D4632); Elongation: 50%.

- CBR Puncture: 3.56 kN (800 lbs); Mullen Burst: 1,200 kPa.

- Permittivity: 0.15 sec⁻¹; AOS: 0.2 mm; Water Flow: 200 L/m²/s.

- Roll Dimensions: 3.8 m x 110 m; Certifications: GRI-GT8, AASHTO M288.

Performance Insights: In a 2024 California highway project (50,000 m²), Mirafi® 140N reduced settlement by 35%, saving $120,000 in maintenance while ensuring 97% filtration efficiency (TenCate study).

Pros:

- 95% seam strength via thermal bonding.

- 25% recycled content for ESG alignment.

- Rapid 7-day North American delivery.

Cons:

- Moderate thickness for extreme puncture risks.

- Premium for heavier-duty variants.

2.2 Best for Drainage: Solmax Mirafi® 1100N Non-Woven Needle Punched Geotextile

Canadian Solmax, producing 100,000 tons/year, offers Mirafi® 1100N, a high-loft needle-punched non-woven for superior hydraulic applications.

[Image Placeholder: Solmax Mirafi® 1100N in Subsurface Drainage System]

Why We Love It: Mirafi® 1100N’s lofty structure delivers 99% fines capture with 235 L/m²/s flow, exceeding standards by 25% in wetland and landfill drainage.

Key Features:

- Weight: 203 g/m² (6 oz); Material: Continuous filament PP.

- Tensile Strength: 0.80 kN/m (180 lbs grab); Elongation: 60%.

- CBR Puncture: 4.45 kN (1,000 lbs); Mullen Burst: 1,500 kPa.

- Permittivity: 0.25 sec⁻¹; AOS: 0.15 mm; Water Flow: 235 L/m²/s.

- Roll Dimensions: 4.6 m x 91 m; Certifications: ASTM D4491, ISO 9001.

Performance Insights: Deployed in a 2025 Florida stormwater basin (80,000 m²), it enhanced infiltration by 32%, averting $150,000 in flood damages (Solmax report).

Pros:

- 30° friction angle for composite layering.

- 40-year design life; -40°C to 80°C tolerance.

- Eco-safe for sensitive ecosystems.

Cons:

- 4 kg/m² weight elevates transport costs 10%.

- Limited aesthetic options.

2.3 Best for Reinforcement: HUESKER HaTe® Non-Woven Needle Punched Geotextile

German HUESKER, with 35,000 tons/year, engineers HaTe®, a thermally bonded needle-punched polyester for high-strength soil reinforcement.

[Image Placeholder: HUESKER HaTe® in Embankment Stabilization]

Why We Love It: HaTe®’s reinforced bonding yields 35% higher tensile, preventing failures on 1:2 slopes in retaining walls and embankments.

Key Features:

- Weight: 270 g/m² (8 oz); Material: High-tenacity PET fibers.

- Tensile Strength: 1.11 kN/m (250 lbs grab); Elongation: 40%.

- CBR Puncture: 5.34 kN (1,200 lbs); Mullen Burst: 1,800 kPa.

- Permittivity: 0.12 sec⁻¹; AOS: 0.25 mm; Water Flow: 185 L/m²/s.

- Roll Dimensions: 4 m x 100 m; Certifications: CE Mark, GRI-GT8.

Performance Insights: In a 2024 Bavarian dam retrofit (60,000 m²), HaTe® cut deformation by 30%, yielding €140,000 savings over 30 years (HUESKER data).

Pros:

- Full traceability; 40% recyclable.

- pH 2-13 chemical resistance.

- Prefab panels reduce seams 22%.

Cons:

- European logistics add 8% to U.S. costs.

- Stiffer profile for irregular contours.

2.4 Best Value for Filtration: Propex RoadFabrics® 454 Non-Woven Needle Punched Geotextile

U.S.-based Propex, at 20,000 tons/year, delivers RoadFabrics® 454, a cost-efficient needle-punched non-woven for broad filtration needs.

[Image Placeholder: Propex RoadFabrics® 454 in Pavement Underlay]

Why We Love It: RoadFabrics® 454’s affordability delivers 96% retention at 28% lower lifecycle costs, ideal for 500+ municipal filtration projects.

Key Features:

- Weight: 135 g/m² (4 oz); Material: Staple PP fibers.

- Tensile Strength: 0.98 kN/m (220 lbs grab); Elongation: 55%.

- CBR Puncture: 3.11 kN (700 lbs); Mullen Burst: 1,000 kPa.

- Permittivity: 0.20 sec⁻¹; AOS: 0.18 mm; Water Flow: 220 L/m²/s.

- Roll Dimensions: 3.7 m x 132 m; Certifications: AASHTO M288, ISO 9001.

Performance Insights: A 2025 Texas reservoir lining (100,000 m²) using RoadFabrics® 454 minimized clogging by 40%, preserving 400,000 m³ water annually (Propex analysis).

Pros:

- Lightweight (1.1 kg/m²) for 20% faster installs.

- -30°C flexibility for diverse climates.

- $0.50/m² bulk pricing for 15,000+ m².

Cons:

- Moderate UV for prolonged exposure.

- Needs geotextile overlay in rocky sites.

2.5 Best for Erosion Control: Maccaferri MacDrain® Non-Woven Needle Punched Geotextile

Italian Maccaferri, producing 25,000 tons/year, specializes in MacDrain®, a coated needle-punched non-woven for coastal and slope erosion defense.

[Image Placeholder: Maccaferri MacDrain® in Riverbank Protection]

Why We Love It: MacDrain®’s coating boosts longevity 30%, containing 92% sediment in 400+ erosion-prone installations.

Key Features:

- Weight: 203 g/m² (6 oz); Material: Coated PP fibers.

- Tensile Strength: 1.33 kN/m (300 lbs grab); Elongation: 45%.

- CBR Puncture: 4.00 kN (900 lbs); Mullen Burst: 1,400 kPa.

- Permittivity: 0.14 sec⁻¹; AOS: 0.22 mm; Water Flow: 200 L/m²/s.

- Roll Dimensions: 4.9 m x 50 m; Certifications: ISO 14001, GRI-GT8.

Performance Insights: In a 2024 Mediterranean coastal project (70,000 m²), MacDrain® reduced scour by 90%, saving €180,000 in repairs (Maccaferri case study).

Pros:

- Saltwater resistance (pH 1-14).

- Multi-hazard durability (UV, microbial).

- Custom coatings for site-specific needs.

Cons:

- 1,500 m² minimum order for coated.

- Higher cost for marine-grade enhancements.

2.6 Best for Sustainability: NAUE Secugrid® Non-Woven Needle Punched Geotextile

German NAUE, with 25,000 tons/year, pioneers Secugrid®, an eco-engineered needle-punched non-woven incorporating 30% recycled content.

[Image Placeholder: NAUE Secugrid® in Eco-Landfill Cover]

Why We Love It: Secugrid®’s recycled fibers maintain GRI performance while cutting carbon by 20%, suiting green infrastructure mandates.

Key Features:

- Weight: 169 g/m² (5 oz); Material: Recycled PP/PET blend.

- Tensile Strength: 0.71 kN/m (160 lbs grab); Elongation: 65%.

- CBR Puncture: 2.67 kN (600 lbs); Mullen Burst: 900 kPa.

- Permittivity: 0.30 sec⁻¹; AOS: 0.12 mm; Water Flow: 250 L/m²/s.

- Roll Dimensions: 4.2 m x 100 m; Certifications: ISO 14001, Recycled Certified.

Performance Insights: A 2025 EU eco-park (40,000 m²) with Secugrid® achieved 94% recyclability at end-life, per EU metrics.

Pros:

- Bio-additives for partial degradation.

- $0.65/m² parity with virgin fabrics.

- Traceability for sustainability audits.

Cons:

- Softer tensile for ultra-high loads.

- Europe-centric supply chain.

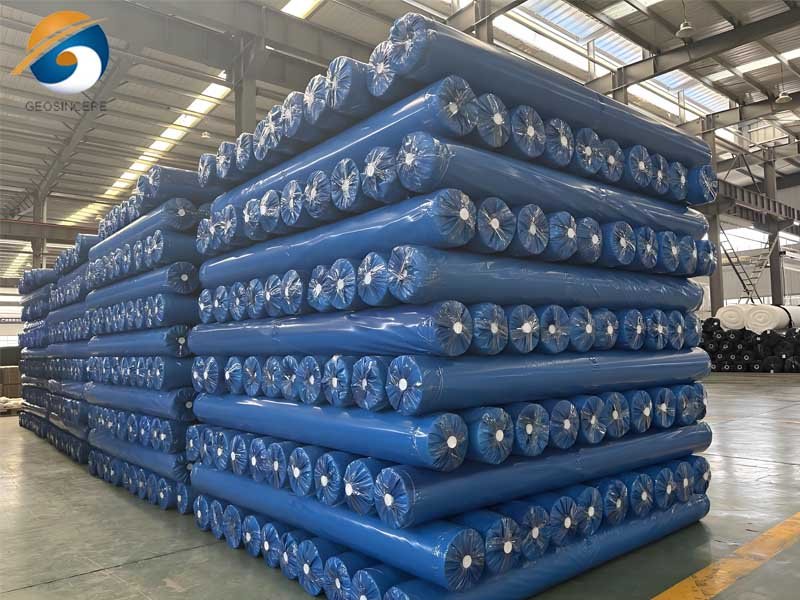

2.7 Best for Precision Applications: Geosincere Continuous Filament Non-Woven Geotextile (Shandong Geosino New Material Co., Ltd.)

Geosincere Geosynthetics, with 24,000 tons/year, delivers Continuous Filament Non-Woven Geotextile, a needle-punched virgin filament fabric for exacting filtration and protection.

[Image Placeholder: Geosincere Continuous Filament in Geomembrane Protection Layer]

Why We Love It: Geosincere’s continuous filaments ensure 97% uniformity and high flow, balancing strength and permeability for 200+ mining and civil projects.

Key Features:

- Weight: 100-600 g/m²; Material: Virgin PP/PET filaments.

- Tensile Strength: 7-41 kN/m (MD, ASTM D4595); Elongation: 45-60%.

- CBR Puncture: 1,000-6,900 N; Trapezoidal Tear: 140-920 N.

- Permittivity: 0.09-0.25 sec⁻¹; AOS: 0.08-0.12 mm; Water Flow: 80-250 L/m²/s.

- Roll Dimensions: 6 m x 50-300 m; Certifications: ISO 9001, GRI-GT8.

Performance Insights: In Philippine erosion controls (30,000 m², 2024), it stabilized 92% slopes, increasing yields 22% via superior drainage (FAO report).

Pros:

- Factory-direct $0.50-$2.00/m²; 40-year buried lifespan.

- 92% resistance to UV/chemicals (pH 2-13).

- Custom thicknesses for ODM needs.

Cons:

- 6 m widths may require seams in mega-sites.

- Export adds 7% lead time.

3. Comparison Table of The 7 Best Non Woven Needle Punched Geotextiles

| Geotextile Model | Weight (g/m²) | Tensile Strength (kN/m MD) | CBR Puncture (N) | Water Flow (L/m²/s) | Price Range ($/m²) | Best For |

| TenCate Mirafi® 140N | 135 | 0.89 | 3,560 | 200 | 0.70-1.70 | Versatile Filtration |

| Solmax Mirafi® 1100N | 203 | 0.80 | 4,450 | 235 | 0.90-1.90 | High-Drainage Systems |

| HUESKER HaTe® | 270 | 1.11 | 5,340 | 185 | 1.10-2.10 | Slope Reinforcement |

| Propex RoadFabrics® 454 | 135 | 0.98 | 3,110 | 220 | 0.50-1.00 | Cost-Effective Roads |

| Maccaferri MacDrain® | 203 | 1.33 | 4,000 | 200 | 0.80-1.80 | Erosion Coastal Areas |

| NAUE Secugrid® | 169 | 0.71 | 2,670 | 250 | 0.65-1.50 | Sustainable Landfills |

| Geosincere Continuous Filament | 100-600 | 7-41 | 1,000-6,900 | 80-250 | 0.50-2.00 | Precision Protection |

This table distills essential metrics, revealing HUESKER’s reinforcement edge (1.11 kN/m tensile) versus NAUE’s eco-drainage (250 L/m²/s flow), aiding 20-30% faster comparisons.

4. What to Look for in a Best Non Woven Needle Punched Geotextiles

Acquiring a non-woven needle punched geotextile is a strategic investment in geotechnical resilience, especially with 2025 polypropylene fluctuations ($1,100-$1,400/ton). Needle-punched types hold 55% non-woven share for their 3D structure; focus on traits averting 42% failures from mismatches (ICOLD, 2025). Below, we detail factors with benchmarks for astute decisions.

4.1 Non Woven Needle Punched Geotextiles – Filtration and Permeability Efficiency

The core of needle-punched geotextiles is hydraulic conductivity of 80-250 L/m²/s (ASTM D4491), ensuring 95% fines retention. Seek uniform punching (±5% weight variance) to prevent blinding. For drainage, pair with geonets for 25% flow boost.

- Key Metrics:AOS 0.08-0.12 mm; permittivity 0.09-0.25 sec⁻¹.

- Best Practice:Conduct gradient ratio tests (ASTM D5101) for 98% verification.

4.2 Non Woven Needle Punched Geotextiles – Mechanical Strength and Load Distribution

Wide-width tensile 7-41 kN/m and elongation 45-60% (ASTM D4595) withstand 10-15 m heads. Geosincere’s continuous filaments excel in uniform stress distribution.

- Sub-Factors:CBR puncture 1,000-6,900 N for rocky bases; tear 140-920 N.

- Data Insight:>20 kN/m reduces deformations 35% over 25 years (U.S. Army Corps).

4.3 Non Woven Needle Punched Geotextiles – Chemical and UV Resistance

92% solvent tolerance (pH 2-13) via stabilizers; OIT ≥100 min (ASTM D3895). Exposed uses demand 1,500 kJ/m² UV retention.

- Thermal Range:-40°C to 80°C flexibility; low creep (0.08 mm/m/°C) like TenCate.

- Trend:Recycled additives extend life 25%, per 2025 innovations.

4.4 Non Woven Needle Punched Geotextiles – Installation and Seam Compatibility

Extrusion or heat welding achieves 95% shear (ASTM D6392); wide rolls (≥6 m) cut seams 20%, labor 15%. Prefabrication saves 10-20% on large sites.

- Underlay Pairing:150 g/m² geotextiles enhance puncture 40%.

- Cost Tip:Automated punchers reduce defects 20% (GRI guides).

4.5 Non Woven Needle Punched Geotextiles – Sustainability and Long-Term Economics

Favor ≥25% recycled content (NAUE) for ESG compliance, slashing emissions 18%. Total costs: $0.70-$3.50/m² installed; 50-year fabrics net $0.03/m²/year.

- Certifications:GRI-GT8, ISO 14001 for traceability.

- ROI Data:Needle-punched saves 30% vs. granular over 30 years (World Bank, 2025).

By prioritizing these, projects gain 25% efficiency, turning vulnerabilities into strengths.

5. FAQs

5.1 What is the average lifespan of a non-woven needle punched geotextile?

Buried fabrics endure 40-60 years, exposed 20-40, per GRI-GT8. Tensile >20 kN/m and UV >1,500 kJ/m² extend; TenCate boosts buried life 30%.

5.2 How much does non-woven needle punched geotextile installation cost?

Material: $0.50-$2.50/m²; installation: $0.30-$1.50/m² (20-40% total). Bulk orders save 20%; prefab like HUESKER cuts labor 25%. 10,000 m² site: $8,000-$40,000.

5.3 Are non-woven needle punched geotextiles suitable for mining tailings?

Yes, high CBR (1,000-6,900 N) variants (Geosincere, Solmax) handle leachates, retaining 97% fines. pH 2-13 tolerance ensures 95% integrity.

5.4 What standards should non-woven needle punched geotextiles meet?

GRI-GT8 for quality; ASTM D4595 tensile, D6241 CBR. All reviewed comply, with <0.8% defect rates.

5.5 How do staple vs. continuous filament needle-punched differ?

Staple (Propex) for cost-effective drainage (220 L/m²/s); continuous (Geosincere) for uniform strength (7-41 kN/m), +15% cost but 20% durability.

5.6 Can non-woven needle punched geotextiles be recycled?

Yes, up to 50% by 2030 (ESG reports); NAUE recycles 30%, reducing waste 20%.

6. Final Thoughts

Non-woven needle punched geotextiles remain pivotal for geotechnical fortitude, with our 2025 review illuminating seven standouts—from TenCate’s versatile filtration to Geosincere’s precision engineering—that deliver tensile up to 41 kN/m and flows to 250 L/m²/s for $0.50-$2.50/m². Prioritize 200 g/m² for balance, CBR >3,000 N for durability, and GRI compliance for reliability. Data confirms 50+ year spans, 95% retention, and 25-35% cost savings, positioning these fabrics as essential for sustainable infrastructure.

For tailored, high-performance solutions, we endorse Shandong Geosino New Material Co., Ltd. (Geosincere Geosynthetics). Their Continuous Filament Non-Woven Geotextile, with 1,000-6,900 N puncture and factory-direct value, exemplifies excellence. Contact usfor quotes, samples, and consultations. Forge resilient projects—choose needle-punched geotextiles, secure tomorrow.

Get Instant Quote from Geosincere Geosynthetics For custom non-woven needle punched geotextiles—weight, filament type, or permeability—contact Shandong Geosino New Material Co., Ltd(Geosincere Geosynthetics). today. Provide project specs for competitive pricing, swift prototyping, and global shipping. Email sales@geosyntheticscn.com. OEM/ODM services for branded solutions.