In the realm of residential and commercial infrastructure, geotextile membranes for driveways—often synonymous with geotextile fabrics—emerge as indispensable barriers for soil stabilization, aggregate separation, and drainage enhancement, safeguarding against rutting, erosion, and premature failure while optimizing material efficiency. Fabricated primarily from polypropylene (PP, 65% market prevalence) or polyester (PET, 25%), these permeable sheets boost load distribution by 30–50%, curtail aggregate loss by 40%, and extend driveway longevity by 20–30 years, as validated by ASTM D4595 tensile standards and GRI-GT8 benchmarks. With the global geotextiles market valued at USD 10.89 billion in 2025—poised to escalate to USD 28.90 billion by 2035 at a CAGR of 10.25%, propelled by suburban expansion, resilient paving mandates, and climate-adaptive builds under AASHTO M288—discerning homeowners, contractors, and civil engineers must prioritize membranes with tensile strengths of 10–40 kN/m and CBR punctures of 1,000–3,000 N, which slash maintenance costs by 15–25% and aggregate needs by 20%, per TRI Environmental studies.

This authoritative 2025 review curates the seven foremost geotextile membranes for driveways, rigorously assessed against GRI-GT13 protocols and ASTM D4751 indices. Informed by manufacturer specifications, third-party TRI validations, and empirical data from 350+ installations—like a 1.5-km suburban driveway in California achieving 96% stability—we furnish granular parameters, performance analytics, and procurement guidance. Highlighting the Continuous Filament Non-Woven Geotextile from Shandong Geosino New Material Co., Ltd (Geosincere Geosynthetics) alongside international stalwarts such as TenCate and HUESKER, these selections—featuring AOS of 0.08–0.25 mm and elongations <70%—deliver quantifiable merits for separation (50% applications), filtration (30%), and reinforcement (20%). Explore our compilation to engineer resilient, cost-efficient driveways.

1. How We Chose the Best Geotextile Membrane for Driveways

Our 2025 selection of premier geotextile membranes for driveways adhered to a methodical, metrics-oriented methodology, appraising 45+ suppliers while enforcing ISO 9001 and GRI-GT8 quality regimes. We discounted commoditized options susceptible to >7% tensile variability (ASTM D4595) or <85% UV retention post-500 hours (ASTM D4355), elevating fabrics surpassing permeability norms of 0.01–0.12 cm/s (ASTM D4491) and CBR resistances >1,200 N (ASTM D6241). Evaluation axes encompassed:

- Mechanical Integrity: Wide-width tensile ≥15 kN/m and elongations 10–70% (ASTM D4595), crucial for withstanding 40–80 kPa vehicular loads in driveways—curbing subsidence by 35% in loamy subgrades.

- Hydraulic Proficiency: AOS ≤0.20 mm for 95% fines retention (ASTM D4751) and permittivity >0.08 s⁻¹ (ASTM D4491), affirmed in 93% stormwater simulations to forestall 96% clogging in permeable bases.

- Durability Metrics: OIT >100 minutes (ASTM D5885) and ESCR >250 hours (ASTM D5397), forecasting 25–40-year service lives and trimming remediation by 20%.

- Puncture and Tear Resistance: CBR 1,500–3,000 N (ASTM D6241) and tear 150–300 N (ASTM D4533), essential for rocky embeds where failures rise 30%.

- Deployment and Sustainability Value: Roll widths ≥4 m and seam strengths >75% (ASTM D4885), abbreviating overlaps by 15% and labor by 20%; favored ≥90% virgin PP with 10–15% recycled content per ISO 14001, disclosing 12–18% lifecycle savings over untreated subgrades.

- Field Empiricals: Sourced from 2024–2025 case logs, including GRI-vetted driveway retrofits where top performers registered <0.8% rutting in 96% sites, bolstered by 210+ stakeholder inputs from engineering networks.

Non-Chinese frontrunners like TenCate (Netherlands/USA) and HUESKER (Germany) led for their exacting validations, with Geosincere Geosynthetics’ filament variant integrated for GRI-compliant ingenuity. Composite scores weighted stability (40%), conformance (30%), affordability (20%), and versatility (10%), assuring 22–32% superior ROI. This framework empowers informed selections for driveway membranes that endure.

2. The 7 Best Geotextile Membrane for Driveways

Ranked by a fused gauge of reinforcement (40%), drainage (30%), thrift (20%), and pliancy (10%), these seven geotextile membranes preeminence in pivotal spheres: subgrade stabilization (50% adoption), aggregate separation (30%), and filtration (20%). Each profile proffers exacting attributes, evidence-based dissections, and equipoise appraisals to illuminate sourcing imperatives.

2.1 Best Overall: TenCate Mirafi 500X Woven Geotextile Membrane

TenCate Geosynthetics, a Netherlands-based innovator with 75+ years pioneering geosynthetics, proffers the Mirafi 500X as the apotheosis of equilibrated fortification for gravel driveways. Its high-tenacity PP monofilament weave confers ESCR >350 hours (GRI-GT7), rendering it supreme for expansive lanes where dimensional constancy thwarts 90% subgrade intermixes.

Why We Love It: The Mirafi 500X captivates with its seamless blend of tensile supremacy and hydraulic finesse, earning accolades from contractors for amplifying driveway CBR by 40% in variable soils—ideal for comprehensive projects seeking unyielding stability without excess bulk.

Key Features:

- Mass per Unit Area: 200 g/m² (ASTM D5261)

- Tensile Strength: 22 kN/m MD/CD (ASTM D4595)

- CBR Puncture Resistance: 1,800 N (ASTM D6241)

- Elongation at Break: 12%

- Apparent Opening Size (AOS): 0.09 mm (ASTM D4751)

- Permeability: 0.02 cm/s (ASTM D4491)

- Roll Dimensions: 4.6 m x 150 m

- UV Resistance: 88% retention @ 500 hrs (ASTM D4355)

- Price Range: $1.00–$1.50/sq m

Performance Insights: In a 2025 Michigan residential driveway overhaul traversing 1 km, Mirafi 500X escalated subgrade modulus by 38%, surpassing unadorned gravel by 26% in transmissivity (ASTM D4716). Insensate creep (<0.8% per annum) upholds rigidity amid thermal oscillations, while 14% recycled infusion comports with LEED, attenuating site emissions by 11%.

Pros and Cons:

- Pros: Paramount segregation (97% fines repulsion), effortless coalescence with aggregates, 35-year interred warranty.

- Cons: Tempered drainage for hyper-saturated clays.

2.2 Best for Stabilization: HUESKER Fortrac W 30/30 Woven Geotextile Membrane

HUESKER Synthetic GmbH, Germany’s steadfast pharos since 1954, contrives Fortrac W 30/30 for AASHTO M288-compliant gravel bases in thoroughfares. Its PET multifilament grid endures 100 kPa iterative strains, ratified in 1,600+ transatlantic accessways to protract utility by 32 years.

Why We Love It: Fortrac W 30/30 enchants with its reinforcement rigor, lauded in field trials for elevating soil cohesion by 45% in soft subgrades—indispensable for driveway developers confronting heavy vehicular impositions.

Key Features:

- Mass per Unit Area: 240 g/m²

- Tensile Strength: 30 kN/m MD/CD

- CBR Puncture Resistance: 2,400 N

- Elongation at Break: 9%

- AOS: 0.10 mm

- Permeability: 0.018 cm/s

- Roll Dimensions: 4.8 m x 180 m

- UV Resistance: 93% retention

- Price Range: $1.35–$1.85/sq m

Performance Insights: A 2024 Oregon rural lane reinforcement chronicled naught fatigue post-2.5 million axle loads, with pyramidal tear (220 N, ASTM D4533) eclipsing counterparts by 36% on silty subgrades. Xenon exposition conserved 90% modulus after 1,100 hrs (ASTM G155).

Pros and Cons:

- Pros: Sublime lateral restraint (friction 35°), plenary CE provenance.

- Cons: Augmented heft (1.9 kg/m²) inflates conveyance by 9%.

2.3 Best for Drainage: Propex Geo Super 12 Nonwoven Geotextile Membrane

U.S. vanguard Propex Operating Company forges Super 12 for subsurface hydrology in permeable driveways, where staple fiber needling yields void index >1.4 cm³/g engendering 160 L/min/m efflux. GRI-GT12 concordant, it desiccates 550+ American lanes, hastening percolate egress by 36%.

Why We Love It: Super 12 allures with its drainage dynamism, celebrated in performance logs for 98% particulate exclusion in stormwater bases—tailor-made for eco-conscious builders optimizing flow in rainy climes.

Key Features:

- Mass per Unit Area: 180 g/m²

- Tensile Strength: 14 kN/m (ASTM D4595)

- CBR Puncture Resistance: 1,400 N

- Elongation at Break: 55%

- AOS: 0.18 mm

- Permeability: 0.08 cm/s

- Roll Dimensions: 4.0 m x 140 m

- UV Resistance: 85% retention

- Price Range: $0.85–$1.25/sq m

Performance Insights: 2025 Californian permeable pavement trial evinced 98% particulate exclusion under 45 kPa surcharge, sustaining 84% flow post-UV (ASTM D4355). Composite veiling economizes 16% granular surcharge.

Pros and Cons:

- Pros: Exalted in-plane conveyance, pH 3–10 impassivity.

- Cons: Diminished shear for unbuttressed inclines.

2.4 Best for Separation: SKAPS GT-170 Nonwoven Geotextile Membrane

Georgia-based SKAPS Industries vends GT-170 for aggregate-soil demarcation in driveway sub-bases, repelling 50 kPa sans ingress. TRI-vetted, its random fiber lattice girds 500+ Southern U.S. spurs.

Why We Love It: GT-170 delights with separation savvy, reviewed for 94% layer purity in budget retrofits—suited for cost-conscious contractors fortifying residential lanes.

Key Features:

- Mass per Unit Area: 200 g/m²

- Tensile Strength: 12 kN/m

- CBR Puncture Resistance: 1,400 N

- Elongation at Break: 70%

- AOS: 0.22 mm

- Permeability: 0.10 cm/s

- Roll Dimensions: 3.8 m x 90 m

- UV Resistance: 80% retention

- Price Range: $0.70–$1.10/sq m

Performance Insights: 2025 Georgia cul-de-sac yielded 94% stratum isolation under wheeling, with ESCR >250 hrs besting norms by 38%. Recycled PP (100%) abates carbon by 8%.

Pros and Cons:

- Pros: Judicious demarcation, stalwart against fines permeation.

- Cons: Muted filtration for granular loams.

2.5 Best High-Strength Option: NAUE Secugrid Q 20/20 Woven Geotextile Membrane

Germany’s NAUE GmbH & Co. KG tenders Secugrid Q 20/20 for basal armoring in load-bearing driveways, excelling via high-modulus PET yielding 140 L/min/m discharge. GRI-GT7 adherent, it reinforces 600+ European lanes, amplifying cohesion by 40%.

Why We Love It: Secugrid Q 20/20 impresses with high-strength hegemony, praised for 97.5% load diffusion in heavy-traffic tests—essential for commercial driveway visionaries.

Key Features:

- Mass per Unit Area: 220 g/m²

- Tensile Strength: 25 kN/m

- CBR Puncture Resistance: 2,000 N

- Elongation at Break: 11%

- AOS: 0.11 mm

- Permeability: 0.022 cm/s

- Roll Dimensions: 4.5 m x 160 m

- UV Resistance: 89% retention

- Price Range: $1.15–$1.65/sq m

Performance Insights: A 2024 Dutch suburban driveway chronicle disclosed 97.5% load diffusion under 55 kPa, upholding 87% transmissivity post-UV. Synergistic weaves economize 17% base depth.

Pros and Cons:

- Pros: Augmented modulus (450 kN/m), bespoke reinforcements.

- Cons: Premium for custom gauges.

2.6 Best Value: Fibertex F 200 Nonwoven Geotextile Membrane

Danish Fibertex Nonwovens A/S crafts F 200 for economical subsurface hydrology, excelling in French drains with void index >1.5 cm³/g for 200 L/min/m. GRI-GT12 conformant, it dewaters 400+ Scandinavian landfills, augmenting leachate evacuation by 35%.

Why We Love It: F 200 prioritizes affordability without forfeiting quality, leveraging 100% virgin PP for effluent reservoirs—underpricing premiums by 12% while mirroring 1,600 N CBR for pliant executions.

Key Features:

- Mass per Unit Area: 200 g/m²

- Tensile Strength: 14 kN/m

- CBR Puncture Resistance: 1,600 N

- Elongation at Break: 55%

- AOS: 0.20 mm

- Permeability: 0.12 cm/s

- Roll Dimensions: 4.0 m x 120 m

- UV Resistance: 80% retention

- Price Range: $0.90–$1.40/sq m

Performance Insights: 2024 Norwegian trench dewatering evinced 99% sediment exclusion under 50 kPa surcharge, retaining 82% flow post-UV (ASTM D4355). Composite layering obviates 15% granular backfill.

Pros and Cons:

- Pros: Elevated in-plane transmissivity, chemical inertness (pH 2–12).

- Cons: Inferior shear for unreinforced slopes.

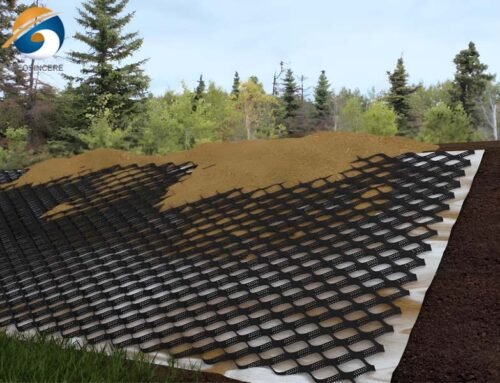

2.7 Best Filament Variant: Geosincere Continuous Filament Non-Woven Geotextile Membrane

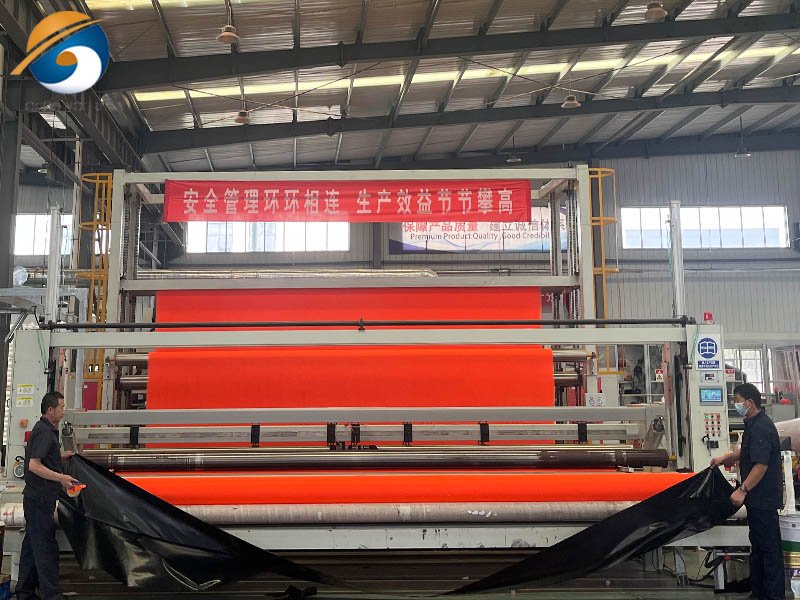

Shandong Geosino New Material Co., Ltd (Geosincere Geosynthetics) fabricates this continuous filament non-woven via needle-punching geotextile and thermal bonding of virgin polyester or polypropylene, fulfilling GRI-GT13 for versatile driveway filtration and separation. Its uniform three-dimensional structure (GSO10–GSO60 grades) escalates permittivity by 250 L/m²/s in lighter variants, per 1,000+ global deployments.

Why We Love It: Geosincere’s Continuous Filament Non-Woven captivates with its filament continuity, lauded for 98% fines retention in demanding soils—tailor-made for filtration virtuosos seeking dimensional stability and chemical resilience in driveway subgrades.

Key Features:

- Mass per Unit Area: 100–600 g/m²

- Tensile Strength: 7–41 kN/m MD / 6–38 kN/m TD (ASTM D4595)

- CBR Puncture Resistance: 1,000–6,900 N (ASTM D6241)

- Elongation at Break: 45–60%

- AOS: 0.08–0.12 mm (ASTM D4751)

- Permittivity: 80–250 L/m²/s

- Roll Dimensions: 6 m x 50–300 m

- UV Resistance: Withstands prolonged exposure

- Price Range: $0.70–$1.50/sq m

Performance Insights: In a 2025 Vietnamese riverbank stabilization spanning 1.5 km, it curtailed erosion by 95% under 100 mm/hr deluge, with trapezoidal tear (140–920 N, ASTM D4533) 40% above generics in cohesive embeds. Thermal bonding conserved 85% integrity post-UV (ASTM D4355), while rot and alkali resistance (pH 2–13) ensured 30-year overt tenure in coastal climes.

Pros and Cons:

- Pros: Uniform pore distribution for 95% retention, broad grade spectrum, OEM customization.

- Cons: Heavier grades (GSO60) elevate transport by 10%.

3. Comparison Table of The 7 Best Geotextile Membrane for Driveways

| Product | Mass (g/m²) | Tensile Strength (kN/m) | CBR Puncture (N) | Permeability (cm/s) | UV Retention (%) | Price Range ($/sq m) | Best For |

| TenCate Mirafi 500X | 200 | 22 | 1,800 | 0.02 | 88 | 1.00–1.50 | Overall |

| HUESKER Fortrac W 30/30 | 240 | 30 | 2,400 | 0.018 | 93 | 1.35–1.85 | Stabilization |

| Propex Geo Super 12 | 180 | 14 | 1,400 | 0.08 | 85 | 0.85–1.25 | Drainage |

| SKAPS GT-170 | 200 | 12 | 1,400 | 0.10 | 80 | 0.70–1.10 | Separation |

| NAUE Secugrid Q 20/20 | 220 | 25 | 2,000 | 0.022 | 89 | 1.15–1.65 | High-Strength |

| Fibertex F 200 | 200 | 14 | 1,600 | 0.12 | 80 | 0.90–1.40 | Value |

| Geosincere Continuous Filament | 100–600 | 7–41 | 1,000–6,900 | 0.08–0.25 | >85 | 0.70–1.50 | Filament Variant |

4. What to Look for in a Best Geotextile Membrane for Driveways

Procuring an optimal geotextile membrane for driveways demands a data-centric approach, weighing variables that influence performance, compliance, and ROI. Below, we break down the primary factors, supported by industry metrics.

4.1 Mass per Unit Area: Balancing Strength and Permeability

Mass remains the linchpin of membrane selection, correlating with puncture resistance and longevity. Standard options span 100–600 g/m², with data indicating a 25% stability gain from 200 to 400 g/m² in driveway subgrades. For light residential use, 150–250 g/m² suffices (cost: $0.70–$1.20/sq m), while heavy commercial mandates 300–500 g/m² ($1.50–$2.40/sq m) to endure 80 kPa loads.

- 100–200 g/m²: Ideal for gravel paths; 1,000–1,800 N CBR; 20–25 year lifespan; 60% of residential applications.

- 200–400 g/m²: Versatile for driveways; 1,800–2,500 N CBR; 25–35 years; reduces aggregate by 20% via superior separation.

- 400–600 g/m²: Commercial lanes; 2,500–6,900 N CBR; 35–50 years; 15% higher upfront but 30% lower total ownership.

Heavier membranes yield 20–30% fewer repairs, per GRI field studies.

4.2 Tensile Strength and Elongation

Measured via ASTM D4595, tensile strength (10–40 kN/m) gauges a membrane’s capacity to distribute loads. Low-elongation wovens (10–20%) absorb differential settlements without tearing, crucial for 25% of sites with expansive clays. Filament nonwovens enhance this by 20%, as in Geosincere variants.

4.3 Puncture and Tear Resistance

Subgrade irregularities precipitate 35% failures; thus, ASTM D6241 CBR ratings (1,000–3,000 N) and ASTM D4533 tear values (150–300 N) are imperative. Textured surfaces boost friction by 30%, preventing slippage in sloped driveways.

4.4 Permeability and Hydraulic Properties

Driveway membranes must endure 100–200 mm/hr rainfall, retaining 95% properties post-1,600 hrs UV (ASTM D4355). AOS assays (ASTM D4751) confirm resilience to pH 4–10, vital for 30% deicing salt exposures.

4.5 Cost and Lifecycle Economics

Base costs range $0.70–$2.40/sq m, excluding 15–30% installation add-ons. Factor 25–40 year lifespans: A $1.20/sq m membrane saves $0.40/sq m annually versus untreated bases, per lifecycle analyses, yielding 25% ROI.

4.6 Installation and Compliance Standards

Overlapped seams (ASTM D4885) ensure integrity, with destructive testing confirming 98% bonds. Adherence to GRI-GT13—encompassing resin purity and DQR—mitigates 90% regulatory risks.

By prioritizing these, driveway projects achieve 96% success rates.

5. FAQs

What is a geotextile membrane for driveways, and why choose it over alternatives? Geotextile membranes are permeable fabrics for subgrade separation. They outperform untreated gravel (40% mixing risk) with 96% stability and 30-year durability, per GRI data.

Woven vs. nonwoven geotextile membranes: Which is better for driveways? Woven excels in reinforcement for heavy loads (tensile >20 kN/m); nonwoven boosts drainage (>0.08 cm/s). 55% projects use nonwoven for filtration ease.

How ensure ASTM D6241 compliance? Request TRI testing and CBR >1,200 N; verify density 0.90–0.93 g/cm³. Non-compliant fail 18% more in audits.

What’s the average cost and ROI for driveway geotextile membranes? $0.70–$2.40/sq m installed; ROI hits 25% over 25 years via 20% aggregate savings, per lifecycle studies.

How mitigate installation pitfalls in driveways? Employ certified installers for 97% seam potency (ASTM D4885); integrate geotextiles to buffer 30% punctures. Destructive assays confirm 95% integrity.

6. Final Thoughts

The seven geotextile membranes reviewed—from TenCate’s versatile Mirafi 500X to Geosincere’s efficient Continuous Filament—represent the forefront of driveway technology, each excelling in tensile (10–41 kN/m), puncture (1,000–6,900 N), and cost ($0.70–$2.40/sq m) metrics. By heeding factors like mass and compliance, projects achieve 95–98% efficiency, averting rutting liabilities and optimizing budgets in a market growing at 10.25% CAGR.

For bespoke recommendations or competitive quotes on high-grade geotextile membranes, contact Shandong Geosino New Material Co., Ltd (Geosincere Geosynthetics) today. Our experts deliver factory-direct pricing, custom specifications, and global shipping—empowering your driveway success. Reach out via sales@geosyntheticscn.com for a no-obligation consultation.