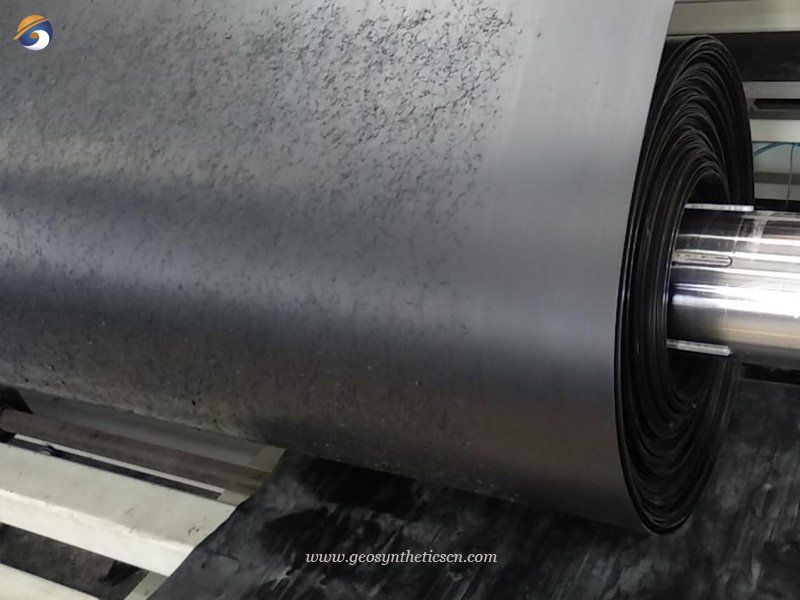

Textured HDPE geomembrane is widely used in mining applications for containment and environmental protection purposes. These impermeable synthetic liners act as barriers against liquid and gas seepage. Textured HDPE geomembranes, with their surface texture, are preferred in mining for several reasons.

The textured surface provides increased frictional resistance, reducing slippage and liner displacement on slopes and in high-traffic areas. It enhances interface friction, improving stability and performance by interacting with surrounding soil or materials. Textured geomembranes conform better to uneven or rough substrates, enhancing geotechnical stability. They also contribute to increased shear strength along the geomembrane-soil or rock interface.

Additionally, the texture reduces slippage potential in movement-prone or unstable areas. Welding textured geomembranes is easier due to the increased surface area for bonding, ensuring better seam integrity. Like smooth HDPE geomembranes, textured ones are resistant to chemicals and UV exposure, making them suitable for various mining applications.

Seepage control is a primary function of HDPE textured geomembranes, and the textured surface further enhances this capability. By preventing the leakage of harmful substances into the environment, textured HDPE geomembranes provide effective seepage control in mining operation

1 Case Study of Textured HDPE Geomembrane for Mining Project in

- Location : Peru

- Product(s) : HDPE Textured Geomembrane

- Application : Mining Project

Why Chose Textured HDPE Geomembrane Peru for Mining Project

Choosing textured HDPE geomembranes for a mining project in Peru offers significant benefits, especially considering the potential environmental hazards associated with mining operations.

The primary motivation for the Peru customers to opt for textured HDPE geomembranes is the need to prevent seepage and protect the environment from the harmful effects of mining activities. Mining involves handling dangerous goods that can cause severe damage to the environment if not properly contained. By installing a layer of protective geomembrane, the customers aim to create a barrier that prevents the leakage of toxic pollutants and the subsequent contamination of groundwater, ensuring environmental safety.

However, the complex terrain of the construction site poses challenges for the installation process. Despite this difficulty, the choice of textured HDPE geomembranes proves advantageous. The textured surface of these geomembranes provides increased frictional resistance and better interface friction. This feature enables the geomembrane to conform to the irregularities of the terrain, enhancing stability and performance, and ensuring effective seepage prevention even in challenging construction environments.

Textured HDPE geomembranes are the best choice for mining project, the Peru customers demonstrate their commitment to environmental protection and responsible mining practices. Despite the construction difficulties posed by the complex terrain, the customers prioritize the implementation of proper protection measures to safeguard the environment and mitigate the risks associated with mining activities.

2 Solution of Textured HDPE Geomembrane Peru for Mining Project

Our engineers have developed a solution for the mining project in Peru by implementing textured HDPE geomembrane slope protection technology. This innovative approach addresses the challenges posed by the complex terrain, ensuring the safety and stability of the slope.

The principle behind this technology lies in the use of an impervious geomembrane that acts as a barrier, preventing rainwater from infiltrating the soil and mitigating the adverse effects of loose soil during rainfall. By maintaining the strength and stability of the slope, it effectively prevents the reduction of mechanical parameters or the increase in self-weight that could lead to slope instability and sliding.

Through the application of HDPE anti-seepage textured geomembrane slope protection and reinforcement technology in the complex broken open-pit slope, even when faced with a large range of cracks caused by rain, the slope remains protected against sliding. This solution ensures the integrity and longevity of the mining project, safeguarding the environment and minimizing the risks associated with mining activities in Peru.

3 Specifications of Textured HDPE Geomembrane for Mining Project in Peru

- Total Textured HDPE Geomembrane quantity–713,440 squares meters

- Thickness – 1.5mm

- Each roll size – 7m*140m

4 Benifits of Textured HDPE Geomembrane for Mining Project in Peru

Textured HDPE geomembrane offers several benefits for mining projects in Peru:

1. Advanced Stabilization:

Textured HDPE geomembrane is specifically designed for landfills and mining applications, providing advanced stabilization. It offers enhanced strength and stability to withstand the demanding conditions of mining sites, ensuring long-term performance.

2. Excellent Interface Friction Coefficient:

The geomembrane’s textured surface provides an excellent interface friction coefficient. This feature is crucial for mining projects as it enhances the stability of the liner and prevents slippage, ensuring the containment of materials and preventing seepage.

3. Inherent Flexibility:

Textured HDPE geomembranes possess inherent flexibility, allowing them to adapt to various contours and irregularities in the terrain. This flexibility facilitates efficient installation, even in challenging environments or complex broken open slopes.

4. Wide Range of Applications:

Textured HDPE geomembranes are versatile and can be utilized in various applications such as backfilled liners, retaining backfills on steep sides, heap leach pads, landfill and pad base liners, as well as water conservancy projects like dams, reservoirs, and sewage pools. They are also suitable for use in buildings, underground structures, and garbage dumps. The adaptability of textured HDPE geomembranes makes them an ideal choice for diverse mining projects.

The benefits of textured HDPE geomembrane, including advanced stabilization, excellent interface friction coefficient, inherent flexibility, and its wide range of applications, make it a reliable and effective solution for mining projects in Peru.

5 Textured HDPE Geomembrane Features

- Can be textured on one or both sides for your demands.

- Increased frictional coefficient for steep slopes.

- Outstanding ultraviolet and chemical resistance.

- Outstanding UV Environmental stress crack resistance.

- High tensile strength and low elongation.

- Excellent friction coefficient and tensile strength with Geotextile reinforcement performance.

- Excellent water impermeability, corrosion and aging resistance.

- Advanced stabilization.

- Impermeable, antifouling, antiskid function.

- Light weight, easy construction and good overall continuity.

6 Textured Geomembrane Installtion Method

Before textured geomembrane installation, the slope surface should be leveled to prevent sharp outburst, and then the loose soil should be covered with impermeable textured membrane.

1) It should be extended from the bottom to the high position, not too tight, and 1.50% margin should be reserved for local sinking and stretching. Considering the actual situation of the project, the slope is laid from top to bottom.

2) The two adjacent longitudinal joints shall not be in a horizontal line, and shall be staggered by more than 1m.

3) The longitudinal joint shall be more than 1.50M away from the dam foot and bending foot, and shall be set on the plane.

4) Slope first and then bottom.

5) When the slope is laid, the film spreading direction should be basically parallel to the maximum slope line.

Slope laying:

Before laying the anti-seepage geomembrane on the slope, the laying area shall be inspected and measured. According to the measured size, the anti-seepage geomembrane with matching size in the warehouse shall be transported to the anchorage ditch platform of phase I. during laying, the convenient way of “pushing” from top to bottom shall be adopted according to the actual site conditions. In the sector area, it should be cut reasonably to make the upper and lower ends firmly anchored.

Site bottom laying:

Before laying the anti-seepage geomembrane, the laying area shall be inspected and measured, and the anti-seepage membrane matched with the size in the warehouse shall be transported to the corresponding position according to the measured size. During laying, the anti-seepage membrane shall be pushed manually in a certain direction.

Alignment and alignment:

The paving of GEOSINCERE HDPE textured geomembrane, no matter the side slope or the bottom of the field, should be flat and straight to avoid wrinkles and ripples, so as to make the two geomembranes aligned and aligned. According to the design requirements, the lap width is generally about 10 cm.

Pressing:

Press the aligned and aligned GEOSINCERE HDPE textured geomembrane with sand bags in time to prevent the wind from blowing and pulling. Laying in Anchorage ditch: at the top of anchorage ditch, a certain amount of impervious membrane shall be reserved according to the design requirements for local sinking and stretching.

Longitudinal joint:

The uphill section is on the upper side and the downhill section is on the lower side, and sufficient lap length ≥ 15cm shall be reserved. The bentonite pad shall be laid in the area after passing the acceptance, and the manual “push paving” shall be carried out in a certain direction.

7 About GEOSINCERE

GEOSINCERE has been dedicated to manufacturing geomembrane and geosynthetics products and solutions to worldwide customers since its foundation in 2007. Our main innovative, high quality products include geotextiles, geomembranes, geogrids, geocells, geosynthetic clay liners, and drainage boards, etc al.

GEOSINCERE offers both high quality geosynthetic products but also professional design and installation service. OEM, ODM, custom development and fabrication are also available. If you have any questions or inquiries, please contact us, we will reply as soon as possible.