RPE pond liner is the waterproof and anti-seepage geotechnical product which can be specially used in the construction of biogas digesters. Because of its long service life, convenient construction, low cost, good seepage resistance, environmental protection and non-toxicity, the rpe kind liner has been widely used in recent years. Various septic tanks, biogas tanks, oxidation ponds, etc. are popularized and promoted, and these tanks lined with HDPE geomembrane pond liner overcome the disadvantages of traditional biogas digesters, which are poor in processing organic matter, not environmentally friendly, difficult to clean, large transportation, and prone to biogas explosions. At the same time, the biogas digesters have the advantages that traditional biogas digesters cannot match and surpass: the organic matter removal rate is high, the COD removal rate is over 78%, and the BOD removal rate is over 82%. Second, it can effectively prevent the sludge from floating up, and through multi-stage filtration, the effluent is neutral, and the sanitary and environmental protection effect is good, and it can basically meet the standard. The third is to obtain a certain amount of high-quality gas-biogas.

Issue

In recent years, with economic development and social progress, the lives of urban residents have been further improved, but there are still many problems in the lives of rural residents. For the grand goal of building a well-off society in an all-round way, developing rural ecological agricultural production methods, improving the rural environment, and increasing farmers’ income, comprehensive utilization of biogas digesters has become an important way to change the rural environment. The construction of a biogas digester can be used for about 20 years. Comprehensive utilization of the biogas digester can not only save energy, improve and protect the environment, but also save chemical fertilizers and pesticides, increase the yield and quality of crops, and promote and drive the development of the breeding industry.

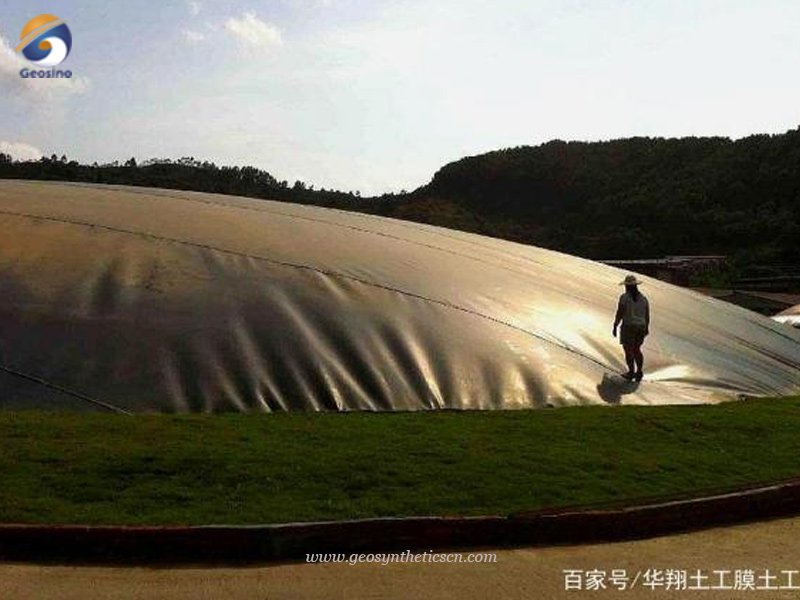

The scientific name of the biogas digester is “fully enclosed anaerobic pond”. The biogas digester with impermeable RPE pond liner integrates fermentation and gas storage. Nowadays, HDPE geomembrane has become the preferred construction material in the construction of biogas digesters. Due to the advantages of HDPE geomembrane liner compared with other materials, the construction price is low. With the characteristics of fast and long service life, the construction of biogas digesters in accordance with the national standard must adopt the CJ-T 234-2006 standard, with a thickness of ≥1.5mm. The entire anaerobic pond is fully enclosed by the impermeable geomembrane RPE pond liner material, which has the advantages of simple, convenient, fast construction, low cost, simple process flow, convenient operation and maintenance, long sewage retention time, sufficient digestion, good sealing performance, and large daily biogas production. The advantages of using biogas to generate electricity, black film absorption of sunlight, warming and heat preservation, automatic sludge discharge device at the bottom of the pond, and less sludge in the pond.

Solution

Biogas digesters, also known as covered lagoons or geomembrane biogas digesters, are popular in farms. They use black HDPE geomembrane covers or liners for fermentation and storage, with black RPE pond liners being common. These liners offer advantages such as easy and fast construction, low cost, convenient operation and maintenance, long sewage retention time, sufficient digestion, and excellent sealing performance. RPE geomembrane material has high tensile strength, resistance to aging and corrosion, effective anti-seepage properties, and good heating and heat preservation effects. It minimizes sludge accumulation with an automatic mud drainage device. Installation of HDPE anti-seepage geomembrane liners involves careful substrate and liner inspection, seams with an overlap width of at least 100mm parallel to the slope, and extrusion welding for secure pipe bonding. RPE pond liners are made from high-quality HDPE geomembrane, meeting standards and offering strong tensile strength, anti-aging and corrosion resistance, and effective anti-seepage properties. They are suitable for different slope sites and are used as the main anti-seepage material in biogas digesters.

Benefits

The black RPE pond liner used in biogas digesters improves fermentation efficiency by absorbing heat. It prevents leakage and follows the anaerobic fermentation process, with a layer of HDPE anti-seepage geomembrane laid on excavated soil. Water inlet, outlet, slag extraction, and biogas collection pipes are installed, with the gas pipeline using ø200mm PE pipe. Anchor ditches are excavated around the pit, and the geomembrane is fixed to create an anaerobic fermentation space. The HDPE impermeable geomembrane pond liner is made of high-quality polyethylene resin with additives and is produced using advanced technology. For base lining, a 1.0mm thick geomembrane is generally used, while the geomembrane cover should be at least 1.5mm thick. The RPE pond liner is non-toxic, cost-effective, and environmentally friendly, solving issues of leakage and corrosion associated with other materials. However, it requires a larger area and additional safety measures for electricity generation.

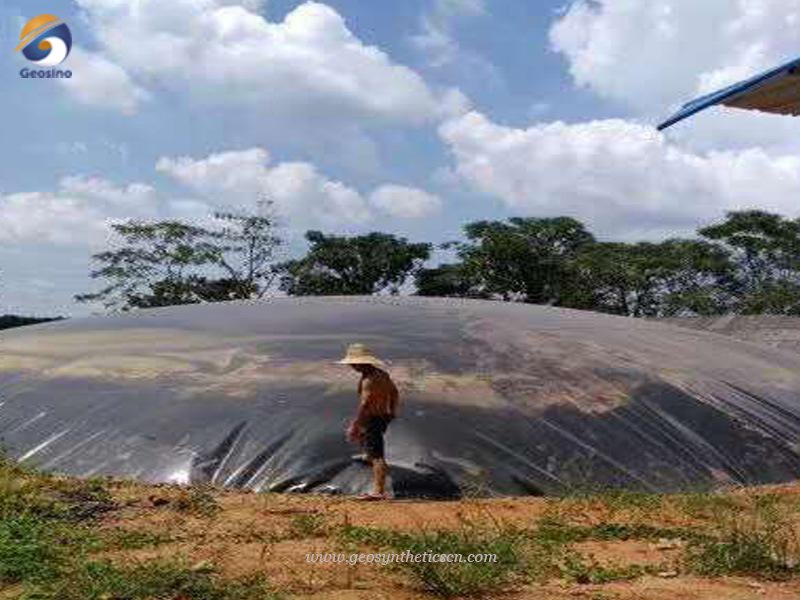

Case Study of RPE Pond Liner for Biogas Digester Project

Black HDPE geomembrane pond liners are used in biogas digesters to automatically separate water and slag, facilitating the removal of biogas residue and allowing the slurry to enter and exit the system. These liners help save sewage treatment fees and improve environmental sanitation by processing farm manure through composting and anaerobic fermentation, reducing pollution and eliminating breeding grounds for harmful organisms. Biogas digesters with these pond liners have large capacities and can daily produce significant amounts of sewage, biogas, and electricity. They offer cost-effective construction and operation compared to traditional digesters and are easy to maintain and repair. The extended retention time and optimal temperature in the tank promote complete fermentation and high biogas production while reducing the COD content of treated sewage. Black geomembrane pond liners are well-suited for pollution control on farms. Construction guidelines for impermeable geomembrane pond liners on slopes include horizontal welding, considering wind direction, adhering to slope requirements, and avoiding welding seams near the bottom.

In May 2021, Indonesia wanted to order HDPE geomembrane products for his biogas digester project. Through email communication, we learned that the area that the biogas digester is basically a brick-concrete structure. The initial use is ideal, but after a period of usage, individual biogas digester was cracked and the collapse phenomenon caused air leakage and could not be used, which caused huge losses to farmers. At the same time, it also had a great negative impact on the later publicized ecological agriculture. The customer found us on the network platform and inquired about our geomembrane product prices, product quality, service life and construction methods, etc. In response to customer doubts and questions, we gave customers detailed answers and sent samples for them as soon as possible. After one week, the customer successfully signed the order contract.

RPE Pond Liner for Biogas Digester Project in Indonesia

- Specifications – 1.0mm (bottom lining), 1.5mm (Cover)

- Each Roll Size – 6*50m

- Quality -125,000㎡

About GEOSINCERE

As the professional geotextile and geosynthetics manufacturer and wholesaler, GEOSINCERE is always committed to geotextile research and development, manufacturing and installation services. We can provide our customers with most extensive lines of geotextiles and geomembranes for civil, mining, environmental and aquaculture engineering applications. GEOSINCERE has been keeping on investing in technological innovation, manufacturing facilities improvement and turnkey engineering abilities. Our extensive lines of geosynthetics products are well known for their ensured quality, high performance, excellent durability and best cost effectiveness. GEOSINCERE brand geotextiles and other geosynthetics products and solutions can meet your requirements by our solid technologies, innovative engineering solutions and excellent customer services. Hope to be your partner.

Our main innovative, high quality products include geotextiles, geomembranes, geogrids, geocells, geosynthetic clay Liner, and drainage boards, etc al. GEOSINCERE customers are from more than 100 countries including America, Australia, France, Sweden, UK, Turkey, Hong Kong, Hungary, New Zealand, Poland, Mexico, Ecuador, Brazil, Pakistan, Bangladesh, Thailand, Vietnam, Malaysia, Indonesia, Singapore, Philippines, Sri Lanka, India, UAE, Saudi Arabia, Qatar, Kenya, Ghana, Ethiopia, Somalia, Nigeria, South Africa, Swaziland, Mongolia, etc.

GEOSINCERE offers both high quality geosynthetic products but also professional design and installation service. OEM, ODM, custom development and fabrication are also available. If you have any questions or inquiries, please fill and submit the following form, we will reply as soon as possible.