Creating or renovating a lake, whether for stormwater management, aquaculture, irrigation storage, decorative landscaping, or habitat restoration, demands a reliable barrier. A leaking lake isn’t just inefficient; it can lead to groundwater contamination, unstable slopes, wasted resources, and costly remediation. The choice of A Lake Liner is paramount. Among the options available, High-Density Polyethylene (HDPE) Geomembrane stands out as the industry-preferred solution for demanding applications. This guide dives deep into why HDPE is often the right choice and how to select the optimal specification for your project.

1. Why the Right A Lake Liner Matters

Before exploring materials, understand the stakes:

- Water Security & Conservation: Prevents precious water from seeping into the ground, crucial in arid regions or for critical water supply.

- Environmental Protection: Contains potentially contaminated water (e.g., stormwater runoff, aquaculture effluent) or protects groundwater from surface pollutants.

- Structural Integrity: Prevents erosion of the subgrade soil, maintaining the lake’s shape and stability.

- Cost Efficiency: Minimizes long-term operational costs associated with water loss and repairs.

- Project Success: Ensures the lake fulfills its intended purpose reliably for decades.

2. A Lake Liner Options: A Quick Comparison

While HDPE is our focus, understanding alternatives provides context:

2.1 A Lake Liner – Clay Liners:

This material is natural and thick, yet it remains permeable. However, it tends to crack and dry over time. Additionally, installation can be challenging—since it’s highly weather-dependent, workers must carefully time the process. Moreover, the labor required is intensive, often demanding skilled hands to ensure proper application. Despite its durability, these factors can limit its practicality in certain conditions.

2.2 A Lake Liner – Bentonite (GCLs):

Geosynthetic Clay Liners (GCLs) outperform natural clay in many ways, providing stronger barriers and greater efficiency. However, they face challenges—repeated hydration and dehydration cycles can weaken them over time. Additionally, sharp objects or heavy loads may puncture the material, compromising its integrity. While GCLs are more reliable than traditional clay, these vulnerabilities require careful handling and proper installation to ensure long-term effectiveness.

2.3 A Lake Liner – LLDPE/LLDPE:

Lower-density polyethylenes (LDPE) are more flexible than HDPE, making them easier to work with in certain applications. However, they offer less chemical resistance and degrade faster under UV exposure. Additionally, they are more susceptible to stress cracking over time, especially under mechanical strain. While their flexibility is an advantage, these trade-offs in durability and chemical stability may limit their use in harsh environments.

2.4 A Lake Liner – PVC (Polyvinyl Chloride):

This material offers flexibility and lower initial costs, making it attractive for many applications. However, it performs poorly in several key areas: its puncture resistance falls short compared to alternatives, and UV exposure causes significant degradation over time. Furthermore, plasticizers gradually leach out, causing embrittlement, while its limited chemical resistance restricts use in harsh environments. Though economical upfront, these durability issues may lead to higher long-term costs.

2.5 A Lake Liner – EPDM (Ethylene Propylene Diene Monomer):

This rubber-like material bends easily, making it ideal for small or complex shapes. However, it tears and punctures more readily than stiffer alternatives. Additionally, oils and hydrocarbons can degrade its structure, while seams—unlike HDPE’s robust fusion welds—often create weak points. Though highly flexible, these limitations may affect its performance in demanding applications.

2.6 A Lake Liner – HDPE geomembrane:

HDPE geomembranes provide superior waterproofing protection while delivering unmatched durability. Their high-density polyethylene composition resists punctures, UV radiation, and chemical corrosion far better than alternatives. Moreover, they maintain structural integrity for decades with minimal degradation. Though installation requires professional welding, the long-term performance outweighs initial effort. Ultimately, HDPE offers the most reliable waterproof solution for demanding environmental applications.

3. HDPE Geomembrane: The Gold Standard for A Lake Liners

HDPE geomembrane has become the dominant choice for large-scale, long-term, and critical lake applications due to its exceptional combination of properties:

3.1 Unmatched Durability & Longevity:

- UV Resistance: Formulated with high-quality carbon black (2-3%), HDPE geomembranes offer superior resistance to ultraviolet radiation, preventing degradation and brittleness for decades (often 50+ years design life).

- Chemical Resistance: Highly resistant to a vast array of chemicals found in soils, water (including acids, alkalis, salts), and biological agents. This is critical for lakes handling agricultural runoff, treated wastewater, or industrial stormwater.

- Biological Resistance: Impervious to root penetration, microbial attack, and rodent damage.

- Temperature Tolerance: Performs well across a wide temperature range (-40°C to +80°C) without significant loss of properties.

3.2 Superior Impermeability:

HDPE has an extremely low permeability coefficient (typically < 1 x 10^{-13} cm/s), effectively creating a water-tight barrier. This minimizes seepage losses to negligible levels.

- High Strength & Puncture Resistance:

While inherently stiffer than PVC or EPDM, modern HDPE formulations offer excellent tensile strength, tear resistance, and crucially, high puncture resistance. This is vital during installation and when resisting potential punctures from underlying rocks, roots, or debris over time.

- Proven Seaming Technology:

HDPE panels are joined using thermal fusion welding (dual hot wedge or extrusion). When performed correctly by certified welders using qualified procedures, this creates monolithic, homogenous seams as strong as, or even stronger than, the parent sheet itself. This seam integrity is fundamental to the liner’s overall performance.

- Cost-Effectiveness Over Lifecycle:

While the initial material cost might be higher than some alternatives like PVC, HDPE’s exceptional durability, minimal maintenance requirements, and long design life translate to the lowest total cost of ownership for most lake projects. Replacement costs and water loss are minimized.

4. Choosing the RIGHT HDPE Geomembrane for Your Lake: Key Specifications

Not all HDPE geomembranes are created equal. Selecting the correct specification is crucial:

4.1 Thickness:

- The single most critical specification. Thickness directly correlates with puncture resistance, durability, and longevity.

- Common Lake Thicknesses: 0.75mm (30 mil), 1.0mm (40 mil), 1.5mm (60 mil), 2.0mm (80 mil).

4.2 Choosing Thickness: Consider:

- Subgrade Quality: Rougher, rockier subgrades demand thicker liners (1.5mm+).

- Water Depth: Deeper water exerts more pressure; 1.5mm+ is often recommended for depths > 15-20 feet.

- Intended Use & Criticality: Decorative ponds might use 0.75-1.0mm; critical water supply or hazardous containment reservoirs typically require 1.5mm+.

- Potential Loads: Anticipated foot traffic, equipment, wave action, or ice formation.

- Local Climate: Freeze-thaw cycles can stress liners.

- Recommendation: For most permanent lakes, 1.0mm (40 mil) is the absolute minimum. 1.5mm (60 mil) is strongly recommended for superior performance, durability, and peace of mind, especially for larger or more critical projects. Never compromise on thickness.

4.3 Resin Quality & Additives:

- Virgin Resin: Demand geomembrane manufactured from 100% primary (virgin) HDPE resin. Recycled content compromises consistency, strength, and chemical resistance.

- Carbon Black: Must be high-quality, finely dispersed carbon black (2-3%) for optimal UV stabilization. Avoid liners with recycled carbon content.

- Antioxidants & Stabilizers: Ensure inclusion of premium additives to enhance long-term resistance to oxidation and environmental stress cracking (ESCR). Look for resins meeting high ESCR standards (e.g., ASTM D5397).

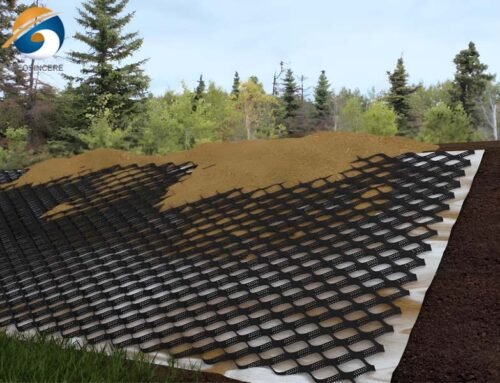

4.4 Textured vs. Smooth Surface:

- Smooth HDPE: Standard surface. Lowest cost, excellent chemical resistance.

- Textured HDPE: Features surface projections (co-extruded or structured). Crucial for applications on slopes:

- Enhanced Interface Friction: Dramatically increases friction between the liner and adjacent materials (geotextile, soil), preventing slippage on steep slopes.

- Improved Drainage: Can facilitate gas/water drainage beneath the liner.

- Recommendation: Use textured HDPE on slopes steeper than 3H:1V (horizontal:vertical). Smooth is often sufficient for flat bottoms and gentle slopes.

4.5 Certifications & Standards:

Ensure the geomembrane meets relevant international and project-specific standards:

- GRI-GM13: Standard Specification for Test Methods, Test Properties, and Testing Frequency for High Density Polyethylene (HDPE) Smooth and Textured Geomembranes (Global benchmark).

- ASTM Standards: Covering material properties, seam testing (e.g., ASTM D6392, D5820, D6693).

- NSF/ANSI 61: Essential if the lake stores potable water.

- CE Marking: Indicates conformity with European health, safety, and environmental standards.

- Manufacturer Quality: Choose reputable manufacturers with proven quality control systems (ISO 9001 certification is a plus). Request certified test reports (CTRs) for the specific roll.

5. Beyond the Membrane: Installation is Paramount

The best HDPE geomembrane is only as good as its installation:

- Subgrade Preparation: The foundation of success. Must be smooth, compacted, free of sharp rocks, roots (> 1″ diameter), debris, and standing water. A protective geotextile cushion is highly recommended over potentially puncturious subgrades.

- Qualified Installers: HDPE welding requires specialized equipment and certified welders. Insist on contractors with proven experience in large-scale HDPE lake liner installations and certified weld technicians.

- Seam Testing: Every single seam must be rigorously tested:

- Destructive Testing (DT): Samples cut from seams and tested in a lab (Peel Test, Shear Test) to verify strength. Frequency per project size/welder.

- Anchoring: Securely anchor the liner in a perimeter trench (“anchor trench”) designed to prevent pull-out.

- Protection: Cover the liner promptly with protective cover soil or sand (typically 12-18 inches minimum) or appropriate ballast (e.g., concrete blocks, riprap) as per design. Avoid exposure to UV for extended periods before covering.

6. Conclusion: Making the Smart Long-Term Choice

Choosing the right lake liner is a critical investment in the success, longevity, and environmental responsibility of your water containment project. While various materials exist, HDPE geomembrane consistently delivers the unparalleled combination of impermeability, chemical resistance, UV stability, puncture strength, and long-term cost-effectiveness required for demanding lake applications.

By prioritizing the correct thickness (1.5mm/60 mil recommended), demanding virgin resin with high-quality carbon black and stabilizers, selecting textured surfaces for slopes, ensuring compliance with key standards (GRI-GM13), and partnering with experienced, certified installers who meticulously prepare the subgrade and rigorously test seams, you ensure your HDPE lake liner will provide a secure, reliable, and leak-free barrier for generations. Don’t settle for short-term savings that lead to long-term headaches; choose HDPE geomembrane as the cornerstone of your lake’s enduring succes.If you have any questions, please contact GEOSINCERE.