When planning a landfill project, whether for municipal solid waste, industrial byproducts, or specialized containment, one of the most critical and often complex cost considerations is the liner system. This is not an area for cutting corners; the liner is the primary barrier protecting groundwater and soil from contamination. Therefore, understanding its cost is paramount. The question “How much does a landfill liner cost?” does not have a single, simple answer. Instead, the price is a composite of several factors, with the geomembrane often being the most significant single component.

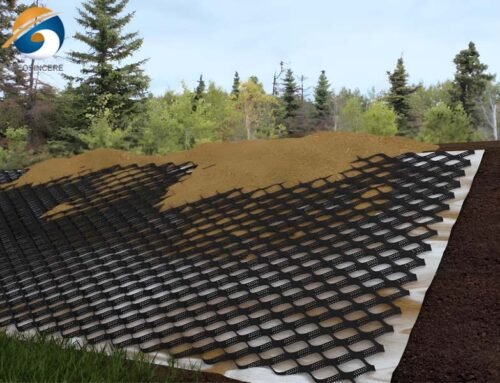

A comprehensive landfill liner system is a sophisticated, multi-layered engineering structure.

1. A typical modern composite liner includes:

- Prepared Subgrade: The excavated and compacted soil base.

- Geotextile Cushion:A protective fabric layer.

- Geomembrane: The flexible, impermeable plastic sheet that is the primary fluid barrier.

- Compacted Clay Liner (CCL): A layer of low-permeability soil.

- Leachate Collection Pipes:A network to remove contaminated liquid.

- Protective Soil Layer: Covering over the pipes.

The cost of the entire system is influenced by the cost of each of these layers and the labor to install them. However, the geomembrane itself is a central cost driver, and its price varies significantly based on material, thickness, and quality.

2. Breaking Down the Cost Factors

The total cost of a landfill liner system can range from $5 to $20 per square foot or more. For a 10-acre landfill (435,600 square feet), this translates to a total liner cost between $2.2 million and $8.7 million. This wide range is due to several key variables:

2.1 Landfill Liner Cost – Material Type (Geomembrane):

2.2 Landfill Liner Cost – Thickness (Gauge)

The thickness, or gauge, of a geomembrane is a direct and significant cost factor. Since geomembranes are sold by weight (cost per square foot), a thicker liner inherently uses more raw polymer, increasing its price. This added expense buys enhanced performance: thicker liners offer superior long-term durability, improved resistance to punctures from the waste above or the subgrade below, and a higher tolerance for installation stresses. While a standard 60-mil HDPE liner might be suitable for many applications, a site with a rocky subbase or heavy, sharp waste may require an 80 or 100-mil liner to ensure integrity. Consequently, selecting the appropriate thickness involves a critical balance between the required performance and the project’s budget, with thicker, more robust liners commanding a premium price.

2.3 Landfill Liner Cost – Project Size and Scale

The principle of economies of scale significantly influences the per-unit cost of a landfill liner system. For very large projects, such as a major municipal landfill, the cost per square foot for both materials and installation typically decreases. This is primarily because material suppliers often provide substantial volume discounts for bulk purchases of geomembranes and geosynthetic clay liners. Furthermore, large, continuous areas allow installation crews to operate more efficiently. They can optimize workflows and utilize specialized machinery with minimal downtime and mobilization costs, which are spread over a much larger area. Consequently, while the total project cost is higher, a 100-acre cell will have a lower cost per square foot than a small, 5-acre closure project, where fixed costs comprise a larger portion of the budget.

2.4 Landfill Liner Cost – Site Preparation

The condition of the subgrade is a critical and often variable cost factor. Extensive site preparation, including excavation, grading, and compaction of the subsoil, is mandatory to create a stable, smooth base for the liner. This prevents punctures and ensures uniform support. The cost of this work is highly dependent on site-specific conditions. A relatively flat site with soft, workable soils will incur minimal preparation expenses. In contrast, a project on rocky, uneven, or sloped terrain will require significantly more labor, heavy machinery, and potentially blasting or extensive cut-and-fill operations. These complex site preparations can be substantial, dramatically increasing the overall project cost before the first roll of geomembrane is even deployed.

2.5 Landfill Liner Cost – Installation Labor

The labor cost for installing a geomembrane liner is a significant component of the overall budget. This specialized work involves multiple skilled tasks: carefully rolling out the heavy geomembrane sheets, precisely scanning them together with thermal welding to create a continuous, impermeable barrier, conducting rigorous quality control tests on every seam, and finally covering the liner with a protective layer. Labor expenses are highly sensitive to site conditions. A simple, accessible site with favorable weather allows for efficient, rapid installation. Conversely, a project with complex terrain, poor accessibility, or frequent adverse weather will drastically slow down the workflow, require more specialized equipment, and increase the total man-hours needed, leading to substantially higher labor costs.

2.6 Landfill Liner Cost – Geographic Location

The final cost of a landfill liner system is heavily influenced by the project’s geographic location, primarily through two key factors: transportation and local labor rates. Manufacturing plants for materials like geomembranes and geosynthetic clay liners are not ubiquitous. The greater the distance from the plant to the job site, the higher the freight costs for these bulky, heavy rolls, directly increasing material expenses. Furthermore, labor rates for the specialized crews required for installation vary significantly by region. Wages, insurance, and overall cost of living are typically higher in major metropolitan areas or regions with strong union presence compared to rural locations. Consequently, identical projects in different states or countries can have substantially different total costs due to these geographic variables.

2.7 Landfill Liner Cost – Regulatory Requirements

Regulatory mandates are a fundamental driver of both the design and cost of a landfill liner system. Stringent local, state, or federal environmental regulations often dictate specific technical requirements that go beyond a basic single liner. For instance, many modern landfills are legally required to install a more robust and expensive composite liner, which combines a geomembrane with a compacted clay layer or a geosynthetic clay liner. These dual-layer systems provide enhanced protection against leachate migration but significantly increase material and installation costs. Furthermore, regulations may mandate stricter quality assurance/quality control (QA/QC) protocols, more frequent monitoring, and the use of certified installers, all of which contribute to a higher final project price but are non-negotiable for compliance and environmental safety.

3. Let’s dissect the factors that create this wide range:

Landfill Liner Cost – Material Selection

The type of geomembrane is the most significant material cost driver.

- HDPE (High-Density Polyethylene): The most common choice for landfills due to its excellent chemical resistance, durability, and cost-effectiveness for large areas. We will explore this in detail later.

- LLDPE (Linear Low-Density Polyethylene): More flexible and stress crack resistant than HDPE, making it better for uneven subgrades. It is often slightly more expensive per mil thickness but can be easier to install.

- PVC (Polyvinyl Chloride): Very flexible and inexpensive, but has poor chemical resistance to many hydrocarbons and is not typically used in primary MSW landfill liners. More common in canals and decorative ponds.

- PP (Polypropylene): Offers good chemical and UV resistance and is often used in exposed applications.

- EPDM (Ethylene Propylene Diene Monomer): A synthetic rubber, extremely flexible but generally not used for primary landfill liners due to cost and susceptibility to certain oils.

4. Landfill Liner Cost – About HDPE Geomembrane :

Given its dominance in the landfill industry, HDPE geomembrane deserves a detailed explanation. Understanding its properties and cost components is key to understanding the overall liner budget.

What is HDPE liner ?

HDPE geomembrane is a impermeable sheet manufactured from high-density polyethylene resin. The resin is combined with additives like carbon black (2-3% for UV resistance), antioxidants, and thermal stabilizers. The mixture is then extruded into flat sheets, which are rolled for shipment. Its widespread adoption is due to a compelling set of engineered properties.

Key Properties and Advantages:

- Excellent Chemical Resistance: HDPE is highly inert and resistant to a wide range of chemical substances, including the acidic and complex leachate generated in landfills. It is unaffected by soil microbes and is an ideal barrier against chemical attack.

- High Durability and Longevity: When properly formulated and installed, HDPE geomembranes have a demonstrated service life exceeding 50 years, and are often engineered for 100+ years of service. They resist environmental stress cracking, a common failure mode in some plastics.

- Low Permeability: The primary function of a barrier is to prevent flow. HDPE has an exceptionally low hydraulic conductivity, effectively making it impermeable to liquids and vapors.

- High Tensile Strength and Puncture Resistance: While not indestructible, HDPE offers a strong balance of strength and flexibility, allowing it to withstand the loads and settlements common in a landfill environment, especially when protected by a geotextile.

- Cost-Effectiveness: On a per-square-foot basis for the performance provided, HDPE is one of the most economical choices for large-scale containment projects.

The Cost Structure of HDPE Geomembrane:

The cost of HDPE geomembrane itself is typically quoted per square foot. This price is driven by several factors intrinsic to the material:

- Raw Material (Resin) Cost: The price of HDPE resin is tied to the global price of petroleum and natural gas. Market fluctuations directly impact the baseline cost of the geomembrane.

- Thickness: As mentioned, this is the most direct cost driver. A simple cost comparison can be made by calculating the relative thickness (e.g., 80 mil is 33% thicker than 60 mil, and the cost will reflect this).

- Carbon Black Content and Quality: High-quality, finely dispersed carbon black is essential for long-term UV resistance. Inferior carbon black can lead to premature degradation. Specifications matter.

- Roll Size: Manufacturers produce rolls in various widths (typically 15-25 feet wide and hundreds of feet long). Wider rolls mean fewer field seams, which can reduce installation costs, but they may be more expensive per square foot and more difficult to handle.

- Manufacturer and Quality Certification: Reputable manufacturers who provide certified materials (e.g., with GRI-GM13 standard test data) may command a premium over generic or uncertified products. This is not an area to cut corners.

Installation and Associated Costs for HDPE:

- Deployment and Paneling: Unrolling the heavy rolls and positioning the sheets on the subgrade requires skilled labor and equipment.

- Seaming (Welding): This is the most critical and costly part of the installation. HDPE panels are joined using specialized welding equipment.

- Dual-Track Fusion Welding: The primary method. Two heated wedges melt the top and bottom surfaces of two overlapping sheets, while a channel between them is left open to allow for pressure and air testing. The cost is typically $1.50 to $3.00 per linear foot of seam, depending on complexity and labor rates.

- Patching and Repair: Any imperfections or damage discovered during installation must be patched, adding to labor time and material use.

- Quality Assurance (QA/QC): For an HDPE liner, this is exhaustive and includes:

- Non-Destructive Testing (NDT): Every inch of every seam is tested using an air pressure test on the dual-track channel.

- Destructive Testing: Sample seams are cut out from the field and tested in a lab for shear and peel strength. This requires patching the sample location.

- CQA Inspector: A full-time, independent inspector is often on-site to oversee all aspects of the installation, from subgrade preparation to final seaming. Their fees are a direct project cost.

5. Conclusion:

While the initial investment for a robust composite liner system with an HDPE geomembrane is substantial—running into millions of dollars for even a modestly sized project—it must be viewed as a non-negotiable investment in environmental protection. The cost of a liner failure, including catastrophic environmental damage, regulatory fines, astronomical cleanup costs, and lasting public liability, dwarfs the initial capital outlay for a properly engineered and installed system.

Therefore, the focus should not be solely on finding the lowest price, but on achieving the best value: a system designed and constructed to the highest standards, ensuring it will perform its vital containment function for generations to come. The cost of the liner is, in reality, the price of safeguarding our water and soil.

6. Choose A Reliable Geomembrane Supplier To Quote Price For You :

GEOSINCERE has been keeping on investing in technological innovation, manufacturing facilities improvement and turnkey engineering abilities. We have invested 10 million dollars into our manufacturing factory which is equipped with state-of-the-art automatic production lines to manufacture high quality HDPE geomembranes and other geosynthetics with optimized processes. Our extensive lines of geosynthetics products are well known for their ensured quality, high performance, excellent durability and best cost effectiveness.

GEOSINCERE brand HDPE geomembranes and other geosynthetics products and solutions can meet your requirements by our solid technologies, innovative engineering solutions and excellent customer services. GEOSINCERE always tries our best to solve the most complex civil, mining and environmental challenges with our innovative and high performance geosynthetic products. Quality assurance, factory price and fast delivery time are our competitive advantages.