In modern civil engineering and infrastructure construction, foundation stability and soil reinforcement have always been key factors affecting project quality and service life. With the advancement of geosynthetics technology, geogrid —high-strength, durable reinforcement materials—are now widely used in roads, railways, dams, slopes, airports, ports, and mining projects.

As part of GEOSINO’s international trade team, we not only supply high-quality geogrid products to clients worldwide but also provide tailored engineering solutions for diverse applications.

1. Basic Concept of Geogrid

1.1 Definition

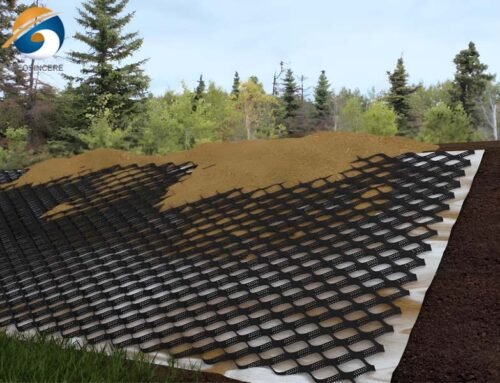

A geogrid is a mesh-like structure made from high polymer materials such as polypropylene (PP), high-density polyethylene (HDPE), or polyester (PET). It features high tensile strength and excellent creep resistance, locking soil or other fill materials within its apertures to enhance overall stability and load-bearing capacity.

Its core function is reinforcement—transferring stress, dispersing loads, and limiting soil displacement through its grid structure, thus improving structural stability and deformation resistance.

Main functions include:

- Reinforcement: Enhances foundation bearing capacity and reduces settlement.

- Separation: Prevents intermixing of different particle sizes in fill materials.

- Confinement: Locks soil particles to reduce lateral displacement.

- Drainage (for certain types): Facilitates water discharge to lower pore water pressure.

1.2 Development History

The development of geogrids can be traced back to the 1970s when the UK-based Netlon company pioneered stretched polymer grid technology. In the early 1980s, Tenax in the United States introduced uniaxial geogrids, further driving technological progress. With advances in polymer science and manufacturing processes, geogrid performance has improved significantly, and its application areas have continued to expand.

2. Main Types of Geogrids

2.1 Uniaxial Geogrid

- Manufacturing: Produced by punching, heating, and stretching PP or HDPE sheets in a single direction.

- Features: High tensile strength in the longitudinal direction, low elongation; ideal for single-direction load-bearing projects.

- Applications: Retaining wall reinforcement, slope stabilization, and foundation load improvement.

2.2 Biaxial Geogrid

- Manufacturing: Similar to uniaxial but stretched in both longitudinal and transverse directions.

- Features: Balanced strength in both directions, suitable for multidirectional stress.

- Applications: Road and railway subgrade reinforcement, airport runways, and port yards.

2.3 Steel-Plastic Geogrid

- Manufacturing: High-strength steel wires encased in polymer materials, processed by welding or molding.

- Features: Extremely high tensile strength, corrosion resistance, suitable for long-term heavy load conditions.

- Applications: Mine tunnel support, heavy-duty platforms, and heavy-haul railway subgrades.

2.4 Polyester Geogrid with PVC/Bitumen Coating

- Manufacturing: Woven from high-strength polyester yarns and coated with PVC or bitumen.

- Features: High tensile strength, excellent creep resistance, chemical resistance.

- Applications: Soft soil foundation reinforcement, pavement overlay reinforcement, and bridge abutment protection.

2.5 Fiberglass Geogrid

- Manufacturing: Woven from glass fibers, coated with bitumen or PVC.

- Features: High tensile modulus, excellent high-temperature resistance, superior aging resistance.

- Applications: Asphalt pavement reinforcement, crack prevention, and reflective crack control.

3. Characteristics and Performance Indicators

3.1 Physical Properties

- Aperture Size & Shape: Square, rectangular, and honeycomb designs are common. Sizes vary from a few centimeters to several tens of centimeters, chosen based on project needs.

- Thickness & Weight: Thicker grids generally offer higher stiffness and strength but also increase material cost and installation complexity.

- Surface Properties: Surface roughness and friction affect interaction with fill material. Some geogrids are embossed or coated to enhance friction.

3.2 Mechanical Properties

- Tensile Strength: Ranges from tens to hundreds of kN/m depending on application requirements.

- Elongation at Break: Low elongation is preferred for stable reinforcement performance.

- Junction Strength: Critical for welded or woven grids, determining overall integrity.

- Creep Resistance: Ensures long-term stability under sustained load.

3.3 Environmental Resistance

- Chemical Resistance: Essential for acidic, alkaline, or saline soil conditions.

- UV Resistance: Enhanced by UV stabilizers or protective coatings.

- Temperature Resistance: Maintains performance in extreme hot or cold climates.

3.4 Testing Standards

Common standards include ASTM, ISO, and GB, covering tensile tests, junction strength, creep testing, and UV resistance tests.

4. Application Fields

4.1 Highways & Railways

- Subgrade reinforcement to reduce settlement and improve bearing capacity.

- Rut prevention and deformation control in asphalt pavements.

- Extended service life of roads.

4.2 Water Conservancy & Dams

- Dam base reinforcement for overall stability.

- Erosion control in combination with geotextiles or geomembranes.

4.3 Ports & Harbors

- Yard reinforcement for heavy equipment operations.

- Prevention of fill material loss.

4.4 Slopes & Retaining Walls

- Slope protection against landslides and collapses.

- Retaining wall reinforcement for higher load capacity.

4.5 Mining & Industrial Sites

- Heavy-duty road reinforcement for mining trucks and equipment.

- Stabilization of tailings and waste piles.

5. How to Select the Right Geogrid

5.1 Define Project Requirements

- Load type (uniaxial or biaxial).

- Bearing capacity requirements.

- Environmental conditions (pH, temperature, moisture).

5.2 Choose the Right Type & Material

- Soft soil: Coated polyester geogrid.

- Heavy-duty roads: Steel-plastic geogrid.

- High-temperature areas: Fiberglass geogrid.

5.3 Check Key Technical Indicators

- Tensile strength (kN/m).

- Elongation (%).

- Junction strength.

- Aging and corrosion resistance.

6. Construction Techniques & Precautions

6.1 Pre-Construction

- Site Preparation: Remove vegetation, roots, sharp objects; level ground; pre-load or replace soft foundation if necessary.

- Material Inspection: Check certificates, appearance, and test reports.

- Construction Plan: Define layout, overlaps, fill materials, compaction requirements, and work sequence.

6.2 Installation

- Direction: Uniaxial grids aligned with the primary stress direction; biaxial grids along the project axis.

- Method: Unroll manually or mechanically; avoid wrinkles; apply tension; fix temporarily with U-pins.

- Overlap & Connection: 30–50 cm overlap or use connectors; sew if applicable.

6.3 Filling & Compaction

- Filling: Match aggregate size to grid aperture; use well-graded, compactable material; avoid organic or corrosive fills.

- Spreading: Evenly from the center outwards; avoid direct heavy machine traffic; initial cover layer 30–50 cm.

- Compaction: Start with light equipment; follow “light to heavy” principle; control thickness to avoid damage.

6.4 Special Sections

- Slopes: Lay perpendicular to slope; leave wrap-around length; connect layers securely.

- Structures: Provide sufficient anchorage length; ensure smooth transitions.

- Variable Foundations: Use different specs for transition zones; enhance connections; add buffer layers if needed.

6.5 Quality Control & Acceptance

- During Installation: Check placement, overlaps, and fill quality.

- Final Inspection: Verify documents, test reports, and conduct load tests if necessary.

- Common Issues: Replace damaged grids; correct insufficient overlaps; recompact as needed.

7. GEOSINO Advantages

As a professional geosynthetics supplier in China, GEOSINO offers one-stop solutions from R&D and production to export:

- Product Variety: Uniaxial, biaxial, steel-plastic, fiberglass, and coated polyester geogrids.

- International Standards: Compliant with ASTM, ISO, and EN standards.

- Customization: Tailored specs and packaging for specific project needs.

- Global Delivery: Exported to over 60 countries across Asia, Europe, the Americas, and Africa.

- Technical Support: Selection guidance, construction solutions, and after-sales service.

8. Conclusion

Thanks to its strength, durability, and cost-effectiveness, the geogrid has become an indispensable reinforcement material in modern construction. From road reinforcement and slope stabilization to complex environments in water conservancy and port projects, it plays a critical role.

GEOSINO will continue to provide global clients with top-quality geogrid products and expert engineering solutions, helping infrastructure projects become safer, more durable, and more economical.

If you are looking for a reliable geogrid supplier, contact our sales team anytime for the latest pricing and technical support.