Plastic geogrid fabric is a commonly utilized material for ground stabilization in road and slope constructions. GEOSINCERE biaxial geogrid fabric, specifically, is a durable option crafted from extruded punched polypropylene plastic. This biaxial geogrid fabric provides reliable reinforcement in multiple directions, enhancing the stability and load-bearing capacity of the soil. Its high-quality construction ensures long-lasting performance in demanding applications. BPM’s biaxial geogrid offers a cost-effective solution for ground stabilization needs, contributing to the durability and longevity of road and slope projects.

1. What is Biaxial Plastic Geogrid Fabric ?

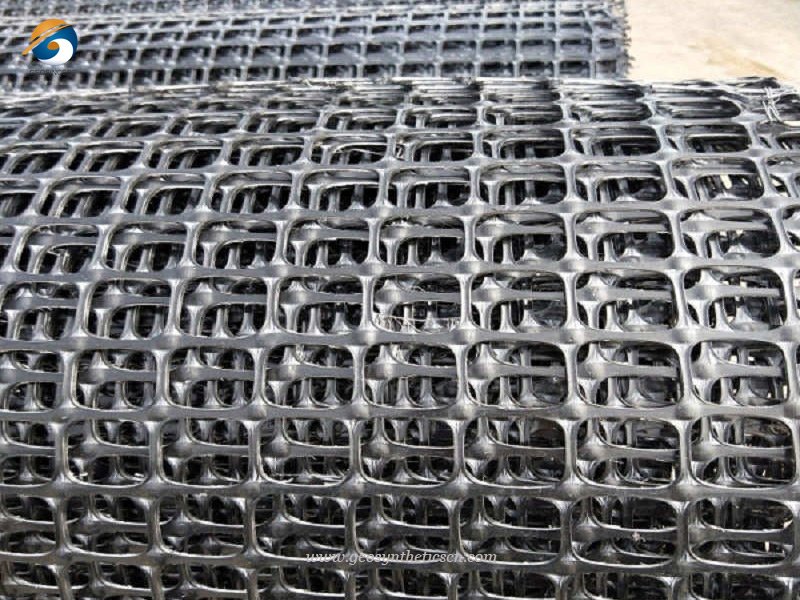

Biaxial plastic geogrid fabric is a versatile geosynthetic material widely utilized in civil engineering and construction projects. It is manufactured by extruding high-density polyethylene (HDPE) or polypropylene (PP) polymers into a sheet, which is then punched and stretched both longitudinally and laterally. This biaxial stretching process enhances the material’s strength and durability.

Application

The main purpose of biaxial plastic geogrid fabric is to provide reinforcement and stabilization to various soil structures. It is commonly employed in embankment and roadbed reinforcement, slope protection, wall reinforcement, and foundation reinforcement for large-scale projects such as airports, parking lots, and freight yards. The geogrid fabric effectively improves the bearing capacity of the road or ground foundation, prolonging its service life. It prevents surface collapse or cracking and helps maintain a neat and aesthetically pleasing appearance.

Advantages

One of the significant advantages of biaxial plastic geogrid fabric is its convenience in construction. It is easy to install, saving time and labor compared to alternative methods. This efficiency contributes to shorter construction periods and reduced maintenance costs. Additionally, biaxial plastic geogrid fabric can replace metal mesh in applications such as coal mine false roof mesh, further expanding its utility.

2. What Is Biaxial Plastic Geogrid Used for?

Biaxial plastic geogrid is used in various civil engineering and geotechnical applications for soil reinforcement and stabilization. It is a high-strength geosynthetic material that consists of intersecting ribs or grids, forming a grid-like structure. Here are some common uses of biaxial plastic geogrid:

2.1 Retaining Walls

Biaxial plastic geogrid is often used in the construction of retaining walls to enhance the stability and strength of the structure. It is placed within the soil layers to distribute and restrain the lateral forces exerted by the retained soil, preventing wall failure and reducing deformation.

2.2 Slope Stabilization

When slopes or embankments are susceptible to erosion, instability, or landslides, biaxial plastic geogrid can be used to reinforce and stabilize the soil. It provides tensile strength to the soil mass, improving its overall stability and preventing slope failure.

2.3 Road and Pavement Construction

Biaxial plastic geogrid is commonly utilized in road and pavement construction projects. It is placed between different layers of soil or aggregate materials to increase the load-bearing capacity and reduce differential settlement. By distributing the applied loads more evenly, it helps to minimize rutting, cracking, and deformation of the road or pavement surface.

2.4 Foundation Improvement

In areas where weak or unstable soils are present, biaxial plastic geogrid can be used to improve the load-bearing capacity of the foundation. It provides reinforcement to the soil, allowing for the construction of foundations on problematic or compressible soils while minimizing settlement and ensuring structural integrity.

2.5 Landfill and Environmental Applications

Biaxial plastic geogrid is also used in landfill and environmental engineering projects. It can be employed to enhance the stability of landfill slopes, prevent erosion, and create barrier systems for waste containment. Additionally, it is used in erosion control and soil stabilization applications for environmental restoration and landscaping projects.

3. What Should Consider When Installing Biaxial Plastic Geogrid?

When installing biaxial plastic geogrid, several factors should be considered to ensure proper installation and optimal performance. Here are some key considerations:

3.1 Site Preparation

Before installing the geogrid, the site should be properly prepared. This includes clearing the area of any vegetation, debris, or sharp objects that could potentially damage the geogrid. The soil surface should be leveled and compacted to provide a stable base for the geogrid installation.

3.2 Design and Engineering

It is important to have a well-designed plan for the geogrid installation that considers the specific requirements of the project. This may involve determining the appropriate geogrid type, strength, and placement based on the soil conditions, anticipated loads, and desired performance objectives. Consulting with a geotechnical engineer or a qualified professional can help ensure the design meets the project requirements.

3.3 Geogrid Placement

The geogrid should be installed in accordance with the design specifications and manufacturer’s recommendations. It is typically placed in the soil layers at the desired depth and orientation, ensuring proper coverage and overlap between adjacent geogrid panels. Care should be taken to avoid stretching, folding, or damaging the geogrid during installation.

3.4 Connection and Anchoring

Proper connection and anchoring of the geogrid are crucial for its effectiveness. The geogrid should be securely fastened to any existing structures, such as retaining walls or abutments, to ensure load transfer and stability. Additionally, the geogrid should be adequately anchored to the soil to prevent movement or displacement.

3.5 Quality Control and Inspection

Regular quality control and inspection during installation are important to verify that the geogrid is being installed correctly and in accordance with the design specifications. This may involve checking for proper alignment, overlap, and anchoring, as well as monitoring for any signs of damage or defects.

4. Cases Study of Plastic Biaxial Geogrid Fabric Colombia for Port Construction Project

- Project name – Biaxial geogrid for port construction in Colombia

- Location – Colombia

- Materials used – geogrid and geocell

Ours customer in Colombia who had a private jetty locally and 和wanted to refit. It is necessary to install cranes on the wharf, which requires a lot of roadbeds. The customer asked us how to improve the strength of the roadbed and reduce the phenomenon of uneven settlement.

Understanding the needs of customers, we recommend biaxially stretched plastic geogrid fabric and geocells to be used together, which will enhance the bearing capacity of the ground. What we recommended is a 20-20KN biaxially stretched geogrid and a 100-356mm geocell. The use of these two products together will enhance the bearing capacity of the roadbed and prolong its service life. And the price is right.

5. Specification of Biaxial Plastic Geogrid Fabric Colombia for Port Construction Project

- Total plastic geogrid fabric Quantity – 30,000 square meters

- Specification of geogrid –Biaxial geogrid 20KN-20KN

- Roll Size -3m * 50m

6. About GEOSINCERE

As the professional geotextile and geosynthetics manufacturer and wholesaler, GEOSINCERE is always committed to geotextile research and development, manufacturing and installation services. We can provide our customers with most extensive lines of geotextiles and geomembranes for civil, mining, environmental and aquaculture engineering applications. GEOSINCERE has been keeping on investing in technological innovation, manufacturing facilities improvement and turnkey engineering abilities. Our extensive lines of geosynthetics products are well known for their ensured quality, high performance, excellent durability and best cost effectiveness. GEOSINCERE brand geotextiles and other geosynthetics products and solutions can meet your requirements by our solid technologies, innovative engineering solutions and excellent customer services.

Our main innovative, high quality products include geotextiles, geomembranes, geogrids, geocells, geosynthetic clay Liner, and drainage boards, etc al. GEOSINCERE offers both high quality geosynthetic products but also professional design and installation service. OEM, ODM, custom development and fabrication are also available. If you have any questions or inquiries, please contact us, we will reply as soon as possible.