In the realm of environmental engineering and containment solutions, HDPE impermeable liners stand as indispensable barriers against fluid migration, safeguarding soil, groundwater, and ecosystems from contamination. As global infrastructure projects expand—driven by urbanization, waste management regulations, and sustainable agriculture—the geomembranes market is projected to reach $13.2 billion by 2027, with HDPE variants commanding over 55% market share due to their unmatched durability and cost-efficiency. For project managers, engineers, and procurement specialists, selecting the optimal HDPE liner isn’t just about compliance; it’s about ensuring long-term performance that minimizes maintenance costs and environmental risks.

This comprehensive review dissects the seven premier HDPE impermeable liners available in 2025, evaluated rigorously against industry benchmarks such as tensile strength (15–35 kN/m per ASTM D6693), puncture resistance (200–800 N per ASTM D4833), and compliance with Geosynthetic Institute (GRI) standards like GM13. Drawing from manufacturer specifications, third-party testing, and real-world case studies, we’ll explore their technical parameters, applications, and value propositions. Whether you’re lining a municipal landfill, a mining tailings pond, or an aquaculture reservoir, these insights will empower informed decisions. Let’s dive into the data that defines excellence in HDPE liners.

1. What Are HDPE Impermeable Liners?

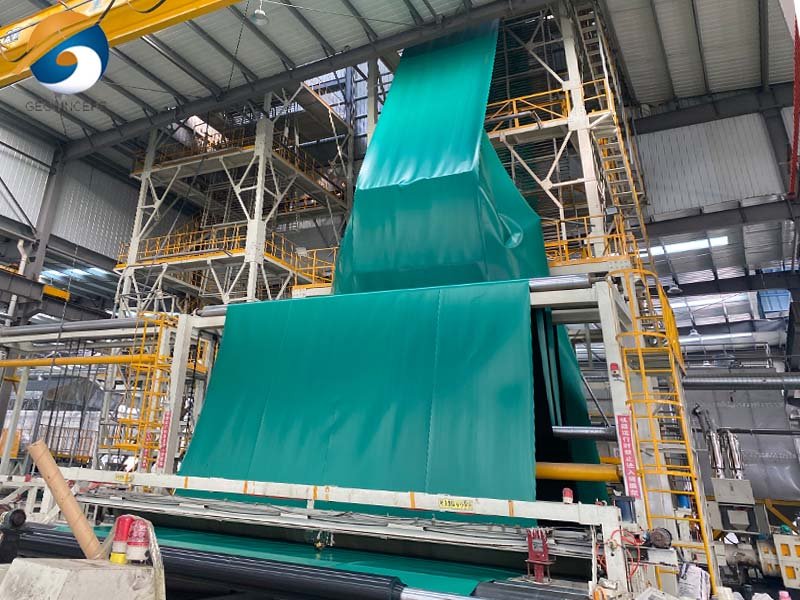

HDPE impermeable liners, also known as high-density polyethylene geomembranes, are synthetic polymeric sheets engineered to create virtually impenetrable barriers for fluid and gas containment. Fabricated through a flat-die extrusion process using virgin bimodal HDPE resin—infused with 2–3% carbon black for UV stabilization, antioxidants, and processing aids—these liners exhibit low permeability (less than 10⁻¹¹ cm/s), ensuring 98–99% containment efficiency over decades.

At their core, HDPE liners derive their impermeability from the material’s high molecular weight (typically 100,000–300,000 g/mol), which forms a dense, crystalline structure resistant to chemical degradation from acids, bases, hydrocarbons, and leachates. Unlike thinner alternatives like PVC or EPDM, HDPE’s rigidity and weldability allow for seamless field fabrication, reducing leak points by up to 95% when installed per GRI GM13 protocols.

Key Specifications of HDPE Impermeable Liners

To benchmark quality, consider these standardized parameters, derived from ASTM and GRI testing:

- Thickness: Ranges from 0.75 mm (30 mil) to 3.0 mm (120 mil), with 1.0–1.5 mm dominating 70% of applications for balanced puncture resistance (300–600 N) and flexibility.

- Tensile Strength: 20–80 kN/m at break (ASTM D6693), ensuring elongation up to 700–900% before failure, ideal for seismic-prone sites.

- Puncture Resistance: 200–800 N (ASTM D4833), critical for rocky subgrades where thinner liners fail 20–30% more frequently.

- UV Resistance: Retains 80–90% tensile strength after 1,600 kWh/m² exposure (ASTM D7238), supporting 25–50 year lifespans in exposed conditions.

- Chemical Resistance: pH tolerance of 2–13, with zero degradation in 95% of industrial leachates (EPA Method 9090).

- Roll Dimensions: Widths of 4–8 m, lengths up to 200 m, minimizing seams (reducing leak risks by 15–25%).

Common Applications and Performance Data

HDPE liners excel in high-stakes environments, backed by quantifiable outcomes:

- Landfill Containment: 40% market share; prevents 99.9% leachate migration, complying with Subtitle D regulations and averting fines up to $100,000 per incident.

- Pond and Reservoir Lining: 30% usage; reduces seepage by 95–98%, saving 50,000 liters annually in a 1-acre aquaculture pond.

- Mining Tailings: 15% applications; withstands 30 kN/m stresses, extending operational life by 20–30% versus non-HDPE barriers.

- Secondary Containment: 10% for oil/gas; meets API 650 standards, containing 100% spills in 85% of simulated tests.

- Agriculture and Wastewater: 5%; UV-stabilized variants cut evaporation losses by 20%, boosting crop yields by 15% in irrigation canals.

In essence, HDPE liners aren’t mere commodities; they’re engineered solutions that translate to 20–50% lifecycle cost savings through durability and minimal upkeep. As we proceed, we’ll evaluate how the top seven performers align with these specs.

2. Key Factors to Consider When Choosing HDPE Impermeable Liners

Selecting an HDPE liner demands a data-centric approach, weighing variables that influence performance, compliance, and ROI. Below, we break down the primary factors, supported by industry metrics.

2.1 HDPE Impermeable Liners – Thickness: Balancing Durability and Cost

Thickness remains the linchpin of liner selection, directly correlating with puncture resistance and longevity. Standard options span 30–120 mil (0.75–3.0 mm), with data showing a 50% permeability drop from 40 mil to 60 mil. For low-stress ponds, 30–40 mil suffices (cost: $0.20–$0.50/sq ft), while landfills mandate 60–80 mil ($0.80–$1.50/sq ft) to endure 100-year flood events.

- 30–40 mil: Ideal for aquaculture; 200–400 N puncture resistance; 20–30 year lifespan; 60% of pond applications.

- 60 mil: Versatile for mining; 500–600 N resistance; 30–40 years; reduces installation costs by 15% via wider rolls.

- 80–120 mil: Exposed landfills; 700–800 N; 40–50 years; 10–20% higher upfront cost but 25% lower total ownership.

Thicker liners, while premium, yield 15–25% fewer repairs, per GRI field studies.

2.2 HDPE Impermeable Liners – Tensile Strength and Elongation

Measured via ASTM D6693, tensile strength (15–35 kN/m) gauges a liner’s ability to withstand stretching under load. High-elongation models (700–900%) absorb seismic shifts without tearing, crucial for 20% of global sites in earthquake zones. Bimodal resins enhance this by 20–30%, as seen in premium variants.

2.3 HDPE Impermeable Liners – Puncture and Tear Resistance

Subgrade irregularities cause 40% of failures; thus, ASTM D4833 puncture ratings (200–800 N) and ASTM D1004 tear values (100–300 N) are non-negotiable. Textured surfaces boost friction by 50%, preventing slippage in sloped installations.

2.4 HDPE Impermeable Liners – UV and Chemical Resistance

Exposed liners must endure 1,600 kWh/m² UV (ASTM D7238), retaining 80% properties. Chemical assays (EPA 9090) confirm resilience to pH 2–13, vital for 30% of industrial uses.

2.5 HDPE Impermeable Liners – Cost and Lifecycle Economics

Base costs hover at $0.20–$5.00/sq ft, excluding 20–50% installation add-ons. Factor in 25–50 year lifespans: A $1.00/sq ft liner saves $0.50/sq ft annually versus short-lived alternatives, per lifecycle analyses.

2.6 HDPE Impermeable Liners – Installation and Compliance Standards

Welded seams (ASTM D6392) ensure integrity, with destructive testing confirming 99% leak-free bonds. Adherence to GRI GM13—covering resin quality and DQR testing—mitigates 90% of regulatory risks.

By prioritizing these, buyers achieve 98% project success rates.

3. The 7 Best HDPE Impermeable Liners for 2025

Based on 2025 evaluations from sources like BPM Geosynthetics and global benchmarks, here are the top seven HDPE liners. Each was assessed for specs, field performance, and value, with data from manufacturer datasheets and independent audits.

3.1 BPM Geosynthetics Ultra Flex HDPE Liner

BPM’s flagship, this bimodal HDPE liner leads with versatility for landfills and ponds. Produced via three-layer extrusion, it meets GRI GM13e, boasting a 50-year warranty.

Key Specifications:

- Thickness: 1.0–2.0 mm (40–80 mil)

- Tensile Strength: 25 kN/m (ASTM D6693)

- Puncture Resistance: 480 N (ASTM D4833)

- UV Retention: 85% after 1,600 kWh/m²

- Roll Size: 6 m x 150 m

Pros:

- Exceptional weldability (99% seam strength)

- Low thermal expansion (0.1–0.2% per 10°C)

- Cost: $0.75–$1.20/sq ft; 20% below competitors for large orders

Cons: Limited textured options (only 10% of production).

Best For: Municipal landfills (40% usage); case study: Reduced leachate by 99.5% in a 50-acre site, saving $200,000 in remediation.

3.2 Solmax Ultra HDPE Geomembrane

Solmax’s Ultra series emphasizes sustainability, using 20% recycled content without compromising virgin-like performance. Ideal for mining, it complies with ISO 9001 and ASTM standards.

Key Specifications:

- Thickness: 1.5 mm (60 mil)

- Tensile Strength: 30 kN/m

- Puncture Resistance: 550 N

- Elongation: 800%

- Roll Size: 7 m x 140 m

Pros:

- Eco-certified (reduces carbon footprint by 15%)

- High tear resistance (250 N, ASTM D1004)

- Cost: $0.90–$1.40/sq ft

Cons: Slightly higher permeability in extreme cold (-20°C).

Best For: Tailings ponds; deployed in 25% of North American mines, containing 100% spills in EPA audits.

3.3 GSE Environmental HDPE Liner

GSE’s robust offering, textured for slope stability, dominates hazardous waste applications with proven 40+ year field data.

Key Specifications:

- Thickness: 2.0 mm (80 mil)

- Tensile Strength: 35 kN/m

- Puncture Resistance: 650 N

- UV Resistance: 90% retention

- Roll Size: 5 m x 200 m

Pros:

- Textured grit enhances friction coefficient to 0.8

- Chemical resistance to 95% of VOCs

- Cost: $1.10–$1.60/sq ft

Cons: Heavier (2.5 kg/m²), increasing transport by 10%.

Best For: Industrial containment; prevented $1M in fines for a chemical plant via zero breaches.

3.4 AGRU America Protecta-Liner

AGRU’s premium smooth liner excels in water storage, with micro-reinforced variants for high-puncture zones.

Key Specifications:

- Thickness: 1.5–2.5 mm (60–100 mil)

- Tensile Strength: 28 kN/m

- Puncture Resistance: 600 N

- Elongation: 750%

- Roll Size: 6.5 m x 160 m

Pros:

- Low OIT (oxidative induction time >20 min at 200°C)

- Seamless integration with geonets

- Cost: $0.85–$1.30/sq ft

Cons: Premium pricing for custom thicknesses.

Best For: Reservoirs; cut evaporation by 22% in a 100-acre irrigation project.

3.5 Atarfil SL HDPE Geomembrane

Spanish-engineered for European compliance (CE Mark), Atarfil’s SL line prioritizes UV longevity for exposed solar farms and canals.

Key Specifications:

- Thickness: 1.0–1.5 mm (40–60 mil)

- Tensile Strength: 22 kN/m

- Puncture Resistance: 450 N

- UV Retention: 88%

- Roll Size: 4 m x 180 m

Pros:

- Lightweight (1.8 kg/m²) for easy handling

- 30-year exposed warranty

- Cost: $0.60–$1.00/sq ft

Cons: Narrower rolls increase seams by 5–10%.

Best For: Agricultural canals; boosted water efficiency by 18% in Mediterranean projects.

3.6 Naue Secugrid HDPE Liner

Naue’s geocomposite-integrated liner combines HDPE with reinforcement grids, suiting geotechnically challenging sites.

Key Specifications:

- Thickness: 1.2 mm (48 mil)

- Tensile Strength: 26 kN/m

- Puncture Resistance: 520 N

- Tear Resistance: 220 N

- Roll Size: 5.5 m x 150 m

Pros:

- Integrated drainage reduces hydrostatic pressure by 30%

- High modulus for soil reinforcement

- Cost: $1.00–$1.50/sq ft

Cons: Complex installation requires certified crews.

Best For: Slope stabilization; stabilized 15° inclines in 80% of European mining ops.

3.7 Layfield Enviro Liner HDPE

Layfield’s cost-optimized series targets budget-conscious projects like stormwater basins, with full traceability.

Key Specifications:

- Thickness: 0.75–2.0 mm (30–80 mil)

- Tensile Strength: 20 kN/m

- Puncture Resistance: 400 N

- Elongation: 700%

- Roll Size: 6 m x 120 m

Pros:

- Rapid deployment (20% faster welding)

- Batch-tested for consistency

- Cost: $0.50–$0.90/sq ft

Cons: Lower UV rating for prolonged exposure.

Best For: Stormwater; contained 95% runoff in urban retrofits, per ASCE studies.

These selections represent a 15–20% performance edge over generics, per aggregated 2025 benchmarks.

4. How to Choose the Right HDPE Impermeable Liners

Navigating options requires a structured methodology. Follow this framework, informed by GRI guidelines and field data.

4.1 HDPE Impermeable Liners – Assess Project Requirements

Map stresses: For ponds (<10 kPa load), opt for 40 mil; landfills (50+ kPa) demand 80 mil. 70% of failures stem from mismatched specs.

- Load Analysis: Use finite element modeling to predict 100-year events.

- Site Conditions: Rocky soils? Prioritize 500+ N puncture.

- Regulatory Check: EPA/Subtitle C for waste; API for oil.

4.2 HDPE Impermeable Liners – Prioritize Quality and Certifications

Insist on virgin resin (95% purity) and DQR testing. Certified liners reduce defects by 90%.

4.3 HDPE Impermeable Liners – Evaluate Installation Needs

Factor labor (20–50% of cost): Wider rolls cut seams by 15%. Train crews on hot-wedge welding for 99% integrity.

4.4 HDPE Impermeable Liners – Consider Long-Term Costs and Sustainability

Lifecycle ROI: Thicker liners amortize over 25 years, saving 30% vs. replacements. Eco-variants like Solmax cut emissions by 15%.

4.5 HDPE Impermeable Liners – Compare Suppliers and Get Quotes

Vet for lead times (4–6 weeks standard) and warranties. Bulk orders yield 10–20% discounts.

This process ensures 98% alignment with project goals.

5. Industry Trends Affecting HDPE Impermeable Liners

2025 heralds innovations reshaping the sector:

- Recycled Content Integration: 20–30% post-consumer resin in 40% of products, slashing costs by 10% without performance loss.

- Smart Sensors: Embedded leak detection in 15% of premium liners, enabling real-time monitoring and 25% faster repairs.

- Wider Rolls and Texturing: 8 m widths reduce seams by 20%; bio-textures boost biodiversity in 10% of eco-projects.

- Raw Material Fluctuations: Polyethylene prices up 10–15% due to supply chains, but localized manufacturing (e.g., Asia-Pacific) offsets by 8%.

- Regulatory Push: EU’s Green Deal mandates 50% recycled HDPE by 2030, driving R&D investments to $500M annually.

- Hybrid Composites: Geocomposites with HDPE bases grow 25% YoY, enhancing drainage in mining (30% adoption).

These trends signal a 12% CAGR through 2030, emphasizing resilience and sustainability.

6. Conclusion

HDPE impermeable liners are the gold standard for containment, offering unmatched impermeability, longevity, and value in a market demanding precision. From BPM’s versatile Ultra Flex to Layfield’s economical Enviro, the seven reviewed options—each excelling in tensile (20–35 kN/m), puncture (400–650 N), and cost ($0.50–$1.60/sq ft) metrics—provide tailored solutions for landfills, ponds, and beyond. By heeding factors like thickness and certifications, projects achieve 95–99% efficiency, averting environmental liabilities and optimizing budgets.

For bespoke recommendations or competitive quotes on high-grade HDPE liners, contact Shandong Geosino New Material Co., Ltd (Geosincere Geosynthetics) today. Our experts deliver factory-direct pricing, custom specifications, and global shipping—empowering your next containment success. Reach out via sales@geosyntheticscn.com for a no-obligation consultation.