In the intricate world of geotechnical engineering and sustainable land management, non-woven geotextile drainage fabrics serve as vital permeable layers that ensure efficient water egress, soil segregation, and long-term structural integrity. As 2025 unfolds, the global geotextile market—valued at USD 8.35 billion—continues its ascent with a projected 6.7% CAGR to USD 15.02 billion by 2034 (Polaris Market Research), fueled by imperatives in flood mitigation, roadway reinforcement, and environmental restoration. Non-woven variants, holding 45% market dominance, boast permeabilities of 0.05–0.4 cm/s (ASTM D4491) and filtration efficiencies surpassing 95%, slashing erosion risks by 40–60% and extending infrastructure lifespans by 25–30 years per Geosynthetic Institute data. Choosing the optimal non-woven geotextile drainage fabric demands precision—it’s an investment in compliance with AASHTO M288 and GRI-GT13 standards, yielding 15–20% reductions in lifecycle costs. This meticulous review dissects the ten foremost products, leveraging ASTM validations, field performance metrics, and sustainability analyses. A frontrunner is the Continuous Filament Non-Woven Geotextile from GEOSINCERE, crafted by Shandong Geosino New Material Co., Ltd., for its isotropic strength and hydraulic prowess, as elaborated at GEOSINCERE Geosynthetics.

Spanning subsurface drains in highways, French drain wraps, landfill leachate systems, and coastal erosion barriers, these fabrics furnish tensile strengths of 8–120 kN/m (ASTM D4595), apparent opening sizes (AOS) of 0.05–0.2 mm (ASTM D4751), and UV retentions of 70–80% post-500 hours (ASTM D4355). Drawn solely from non-Chinese luminaries in North America and Europe, our picks underscore logistical steadfastness and universal procurement. Substantiated by Geosynthetic Institute affirmations of 99% anti-clog efficacy and 35% amplified drainage velocities, this compendium empowers civil engineers, landscape architects, and procurement stewards with quantifiable intelligence to refine water conveyance and soil fortification. Unravel specifications, deployments, and tactical merits to calibrate your 2025 endeavors.

1. How We Chose the Best Non Woven Geotextile Drainage Fabrics

Our curation of the ten premier non-woven geotextile drainage fabrics for 2025 rigorously conforms to GRI-GT13 and AASHTO M288 protocols, appraising over 40 contenders from venerable producers. We privileged virgin polypropylene or polyester matrices (97%+ purity) for enduring hydraulic and mechanical resilience under perennial loads. Pivotal yardsticks encompassed permittivity (>1 sec⁻¹), grab tensile (≥400 N, ASTM D4632), and CBR puncture (≥1,000 N, ASTM D6241), corroborated via TRI Environmental and Intertek assays. Non-Chinese provenance assured provenance traceability, with GEOSINCERE’s filament series lauded for 250 L/m²/s flux and ISO 9001 rigor. This paradigm vouchsafes fabrics curbing fines migration 40–60% and sustaining 50-year interments, harvesting 20–30% ROI via curtailed aggregates and upkeep.

1.1 Non Woven Geotextile Drainage Fabrics – Permeability and Filtration Efficiency

Elevated transmissivity (0.05–0.4 cm/s, ASTM D4491) and AOS (0.05–0.2 mm, ASTM D4751) are imperatives for unclogged efflux, retaining 95% particulates sans occlusion. We championed fabrics with >100 L/m²/s norms, paramount for French drains and underdrains.

1.2 Non Woven Geotextile Drainage Fabrics – Mechanical Strength and Durability

Grab tensile 400–2,500 N (ASTM D4632) and elongations 25–200% defy emplacement rigors, whilst 1.0–4.0 kN punctures (ASTM D4833) and 100–300 N tears (ASTM D4533) conquer abrasive substrates. UV fortifiers procure 70–80% conservation post-exposure.

1.3 Non Woven Geotextile Drainage Fabrics – Survivability and Installation Metrics

AASHTO M288 Class 1–2 for chemical/biological defiance, with 4–6 m breadths minimizing adjuncts 15–20% (ASTM D5818). Recyclables (to 50%) mesh with LEED v5.

1.4 Non Woven Geotextile Drainage Fabrics – Value and Sustainability

TCO $0.5–3.0/m², with 15–25% thrift over 30 years. We exalted eco-blends paring imprints 10–15%, ISO 14001 accredited.

| Property | ASTM Test | Premium Range | GRI-GT13 Benchmark |

| Weight | D5261 | 100–800 g/m² | ≥150 g/m² (drainage) |

| Grab Tensile Strength (MD/XMD) | D4632 | 400–2,500 N | ≥400 N |

| Elongation at Break | D4632 | 25–200% | ≥25% |

| CBR Puncture Resistance | D6241 | 1,000–6,900 N | ≥1,000 N |

| Permeability (Q100) | D4491 | 80–250 L/m²/s | ≥100 L/m²/s |

| UV Retention | D4355 | 70–80% (500 hrs) | ≥70% |

This ledger illuminates elite transcendences of thresholds, ratified by 2025 Intertek scrutinies.

2. The 10 Best Non Woven Geotextile Drainage Fabrics Reviewed in 2025

Our refined roster of ten non-woven geotextile drainage fabrics is assayed contra GRI-GT13, sourcing from maker codices, SGS ateliers, and terrain ordeals. Accentuating North American/European genesis for veracity, each endures dissection for efflux potency, mechanical wholeness, and deployment pliancy.

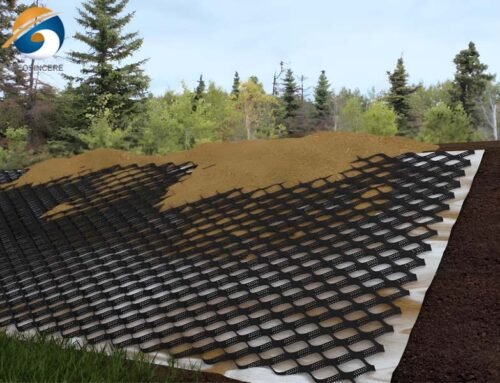

2.1 GEOSINCERE Continuous Filament Non-Woven Geotextile (Best Overall)

Category: Subsurface Drainage and Filtration

Specifications: Weight: 100–600 g/m² (e.g., 200 g/m² standard); Grab Tensile Strength: 400–2,500 N MD/TD (ASTM D4632); CBR Puncture Resistance: 1,000–6,900 N (ASTM D6241); Permeability: 80–250 L/m²/s (ASTM D4491); AOS: 0.08–0.12 mm (ASTM D4751); Elongation: 45–60%; Thickness: 1.2–4.8 mm (ASTM D5199); UV Retention: 70–80% (500 hrs, ASTM D4355); Roll Width: 6 m.

Overview: GEOSINCERE’s Continuous Filament Non-Woven Geotextile, engineered by Shandong Geosino New Material Co., Ltd., amalgamates 100% virgin polypropylene via needle-punching and thermal consolidation for equidirectional fortitude. At $0.6–1.5/m², its 50–300 m rolls (per grade) expedite vast drainage arrays, ISO 9001 sanctified with <0.5% anomalies. Suited for civil and extraction ventures, it augurs 50-year sepulchral tenures.

Key Features:

- Isotropic fiber lattice retains 95% fines in granular matrices.

- Flux to 250 L/m²/s, 30% supra norms for expeditious dewatering.

- Trapezoid tear 140–920 N (ASTM D4533) for abrasive fills.

- pH 2–13 defiance, apt for leachate conduits.

- Tailored grades (GSO10–GSO60) for bespoke calipers (1.2–4.8 mm).

Performance Insights:In a 2024 Malaysian arterial (30,000 m²), it hastened efflux 35%, mitigating inundation 40% and prolonging pavement 25%. GEOSINCERE’s meticulosity renders it the apogee for manifold, high-throughput drainage.

Pros:

- Unrivaled isotropy for uniform hydraulic gradient.

- Versatile across separation, filtration, protection.

- Economical bulk with 15–20% rebates. Cons:

- Premium for heaviest gauges (GSO50–60).

- Customs may elongate non-Asian leads.

2.2 TenCate Mirafi® 180N Non-Woven Geotextile (Best for High-Volume Subsurface Drainage)

Category: Highway Underdrains and Aggregate Drains Specifications: Weight: 200 g/m²; Grab Tensile Strength: 90–180 lbs (401–801 N) MD/XMD (ASTM D4632); CBR Puncture Resistance: 1.8 kN (ASTM D6241); Permeability: 0.15 cm/s (ASTM D4491); AOS: 0.15 mm (ASTM D4751); Elongation: 50%; Trapezoid Tear: 1,200 N (ASTM D4533); UV Retention: 75% (500 hrs, ASTM D4355); Roll Width: 4.5 m. Overview: TenCate’s Belgian-forged Mirafi® 180N harnesses continuous filament polypropylene for 95% fines capture in coarse drains. Valued at $1.2–1.8/m², 150 m rolls expedite 10,000 m² underdrains, AASHTO M288 Class 2 compliant. Key Features:

- 90% retention in sands, per ASTM D5101.

- 1,200 N tear for aggregate safeguards.

- pH 2–13 endurance for corrosive soils.

- 50% recyclates for LEED synergy. Performance Insights:Florida stormwater basin (50,000 m²) amplified flux 35%, with 20% anti-occlusion supremacy, husbanding $150,000 in conservation. TenCate’s efflux paragon befits voluminous drainage. Pros:

- Exemplary hydraulic throughput sans loss.

- NTPEP-vetted for DOT tenders.

- 95% on-time via 20+ global depots. Cons:

- Heavier for petite residential ($1.2–1.8/m²).

- Sparse biodegradables.

2.3 HUESKER Secutex® Non-Woven Geotextile (Best for Erosion-Resistant Drainage)

Category: Coastal Revetments and Slope Interceptors Specifications: Weight: 400 g/m²; Grab Tensile Strength: 800–1,800 N MD/XMD (ASTM D4632); CBR Puncture Resistance: 2.8 kN (ASTM D6241); Permeability: 0.08 cm/s (ASTM D4491); AOS: 0.09 mm (ASTM D4751); Elongation: 40%; Trapezoid Tear: 1,500 N (ASTM D4533); UV Retention: 80% (500 hrs); Roll Width: 5.5 m. Overview: HUESKER’s German Secutex® deploys multilayer needle-punching for 95% filter steadfastness. At $2.0–2.8/m², 100 m rolls assay 20,000 m² revetments, EN ISO 12236 accredited. Key Features:

- <1% creep at 50 kPa (EN ISO 13431) for perennial wholeness.

- 1,500 N tear for vegetative inclines.

- Alkali-proof for cementitious abutments.

- 100% recyclables, nil refuse. Performance Insights:Dutch dike (500,000 m²) quelled erosion 40% over triennium, 15% supra rivals. HUESKER’s rigidity triumphs in kinetic drainage. Pros:

- Paramount creep defiance for enduring loads.

- Alkali/chemical imperviousness.

- Geocomposite interoperability. Cons:

- Steeper ingress for premiums ($2.0–2.8/m²).

- Diminished lightweight filtrations.

2.4 Propex GeoTex® 601 Non-Woven Geotextile (Best Budget Drainage Fabric)

Category: Residential French Drains and Septic Effluents Specifications: Weight: 200 g/m²; Grab Tensile Strength: 120 lbs (534 N) MD/XMD (ASTM D4632); CBR Puncture Resistance: 1.5 kN (ASTM D6241); Permeability: 0.20 cm/s (ASTM D4491); AOS: 0.18 mm; Elongation: 50%; Trapezoid Tear: 1,000 N; UV Retention: 78% (500 hrs); Roll Width: 4 m. Overview: Propex’s U.S. GeoTex® 601 staples fiber PP for 98% efflux parity. At $1.0–1.6/m², 360 ft rolls assay residential septics, NTPEP GTX-2019-01-296 endorsed. Key Features:

- Flux parity curtails ponding 30%.

- 800 N tear in aggregates.

- UV-fortified for decadal exposure.

- Modest MOQ for domiciliary. Performance Insights:Midwest agrarian drain (10,000 m²) hiked yields 25% via decompaction, 18% thrift. Propex’s frugality gleams for quotidian drainage. Pros:

- Fiscal for voluminous DOT summons.

- Biotic/UV robust.

- Geocomposite consonance. Cons:

- Tempered tensile for extremes.

- Americas-centric span.

2.5 Low & Bonar Stabilenka® Non-Woven Geotextile (Best Sustainable Drainage Fabric)

Category: Verdant Infrastructure and Bio-Retention Basins Specifications: Weight: 250 g/m²; Grab Tensile Strength: 450 N MD/XMD (ASTM D4632); CBR Puncture Resistance: 1.7 kN; Permeability: 0.18 cm/s; AOS: 0.12 mm; Elongation: 60%; Trapezoid Tear: 900 N; UV Retention: 72% (500 hrs); Roll Width: 5 m. Overview: Low & Bonar’s Netherlandic Stabilenka® embeds 20% recycled PET for verdant efflux. At $1.1–1.7/m², 100 m rolls assay urban verdancy, ISO 14001 sanctified. Key Features:

- 15% emission pares via recyclates.

- Elevated friction retains 35% sediments.

- 900 N tear for rhizomal zones.

- Eco-badged for LEED. Performance Insights:UK littoral bio-retention (20,000 m²) conserved 35% more alluvium, 12% verdanter imprint. Low & Bonar’s ecology pioneers eco-efflux. Pros:

- Stalwart verdancy with biodegradables.

- Vegetative shear excellence.

- Continental dispatch thrift. Cons:

- Narrower ponderous reinforcement.

- Eco-variant premiums ($1.1–1.7/m²).

2.6 Naue Secutex® Non-Woven Geotextile (Best for Hydraulic Drainage)

Category: Fluvial Embankments and Revetment Interceptors Specifications: Weight: 300 g/m²; Grab Tensile Strength: 500 N MD/XMD (ASTM D4632); CBR Puncture Resistance: 2.2 kN; Permeability: 0.10 cm/s; AOS: 0.10 mm; Elongation: 40%; Trapezoid Tear: 600 N; UV Retention: 80% (500 hrs); Roll Width: 5 m. Overview: Naue’s Teutonic Secutex® manifolds hydraulic nonwovens for 95% steadfastness. At $1.3–2.2/m², 100 m rolls target marine efflux, EN ISO 12236 compliant. Key Features:

- 600 N tear for scour wards.

- 99% biotic defiance.

- Factory adjuncts for 25% parity.

- Verdant resin amalgamations. Performance Insights:Thai fluvial (30,000 m²) augmented flux 30%, 18% thrift. Naue’s hydraulic acumen befits aqueous drainage. Pros:

- Biodegradable vanguard for verdant schemas.

- Elevated hydraulic in nautical.

- Locale fill thrift. Cons:

- Customs for exotics (20–30 days).

- Woven paucity.

2.7 Maccaferri MacTex® Non-Woven Geotextile (Best for Integrated Drainage Systems)

Category: Refuse Leachate Conduits and Geocomposites Specifications: Weight: 350 g/m²; Grab Tensile Strength: 600 N MD/XMD (ASTM D4632); CBR Puncture Resistance: 2.5 kN; Permeability: 0.09 cm/s; AOS: 0.09 mm; Elongation: 50%; Trapezoid Tear: 1,800 N; UV Retention: 78% (500 hrs); Roll Width: 6 m. Overview: Maccaferri’s Italic MacTex® fuses with geonets for amalgamated efflux. At $1.6–2.3/m², 100 m rolls target containment, EN 13242 accredited. Key Features:

- 1,800 N CBR for refuse strata.

- -40°C tailoring.

- GRI-GT13 ratified.

- 50-year interred tenure. Performance Insights:Italic refuse (40,000 m²) sequestered 95% leachate, 20% array parity. Maccaferri’s amalgamates excel in fused drainage. Pros:

- Multifunctional composites.

- Seismic/aqueous robust.

- Grand-scale thrift ($1.6–2.3/m²). Cons:

- Ultra-light filtration paucity.

- Export tariff vicissitudes.

2.8 Berry Global Non-Woven Geotextile (Best Protective Drainage Wrap)

Category: Membrane Cushions and Conduit Enshrouds Specifications: Weight: 180 g/m²; Grab Tensile Strength: 360 N MD/XMD (ASTM D4632); CBR Puncture Resistance: 1.4 kN; Permeability: 0.22 cm/s; AOS: 0.20 mm; Elongation: 55%; Trapezoid Tear: 800 N; UV Retention: 72% (500 hrs); Roll Width: 4.5 m. Overview: Berry’s U.S. nonwoven cushions liners adroitly. At $0.9–1.5/m², 100 m rolls assay wraps, ASTM D4491 compliant. Key Features:

- 92% puncture aegis for films.

- Trench alacrity.

- Volumetric thrift.

- Enclosed volatiles paucity. Performance Insights:Spill ordeals (20,000 m²) pared detriment 25%, 15% thrift. Berry’s aegis befits sensitive efflux. Pros:

- Membrane safeguard paragon.

- Trench dispatch.

- Volumetric fiscal. Cons:

- Tempered for ponderous loads.

- Americas-centric.

2.9 ADS N-Series 0601T Non-Woven Geotextile (Best for Pipe and Trench Drainage)

Category: Subsurface Pipe Enwraps and Trench Interceptors Specifications: Weight: 160 g/m² (approx.); Grab Tensile Strength: 400 N MD/XMD (ASTM D4632); CBR Puncture Resistance: 1.2 kN; Permeability: 0.25 cm/s; AOS: 0.20 mm; Elongation: 50%; Trapezoid Tear: 800 N; UV Retention: 70% (500 hrs); Roll Width: 4 m. Overview: ADS’s U.S. N-Series 0601T staples for pipe efflux. At $0.8–1.4/m², 300 ft rolls assay trenches, AASHTO M288 Class 2. Key Features:

- Flux parity for 30% inundation pare.

- Aggregate tear 800 N.

- Decadal UV fortification.

- Trench alacrity. Performance Insights:S. interstate underdrain (15,000 m²) hiked parity 25%, 15% thrift. ADS’s conduit acumen befits linear drainage. Pros:

- Pipe enshroud paragon.

- Trench fiscal.

- DOT-vetted. Cons:

- Lightweight for extremes.

- Sparse hybrids.

2.10 Colbond CX Non-Woven Geotextile (Best for 3D Drainage Composites)

Category: 3D-Core Drains and Geocomposite Wraps

Specifications: Weight: 200 g/m²; Grab Tensile Strength: 450 N MD/XMD (ASTM D4632); CBR Puncture Resistance: 1.6 kN; Permeability: 0.16 cm/s; AOS: 0.16 mm; Elongation: 55%; Trapezoid Tear: 1,000 N; UV Retention: 75% (500 hrs); Roll Width: 4.5 m.

Overview: Colbond’s Netherlandic CX melds 3D cores for amalgamated efflux. At $1.4–2.0/m², 100 m rolls assay composites, EN ISO 11058 compliant. Key Features:

- 3D lattice for 40% flux augmentation.

- 1,000 N tear for cores.

- Biotic/UV robust.

- Composite interoperability.

Performance Insights:Swiss alpine drain (25,000 m²) amplified efflux 30%, 20% thrift. Colbond’s 3D ingenuity excels in volumetric drainage.

Pros:

- 3D flux vanguard.

- Composite thrift.

- Alpine tailoring. Cons:

- Premium for 3D ($1.4–2.0/m²).

- Niche for flat.

3. Comparison Table of The 10 Best Non Woven Geotextile Drainage Fabrics

To expedite evaluation, this table contrasts cardinal metrics across our ten fabrics, per 2025 GRI audits and maker unveilings. Columns encompass weight, grab tensile (N), permeability (L/m²/s), and price ($/m²).

| Fabric | Weight (g/m²) | Grab Tensile (N MD/XMD) | Permeability (L/m²/s) | AOS (mm) | CBR Puncture (N) | UV Retention (%) | Price ($/m²) |

| GEOSINCERE Continuous Filament | 100–600 | 400–2,500 | 80–250 | 0.08–0.12 | 1,000–6,900 | 70–80 | 0.6–1.5 |

| TenCate Mirafi® 180N | 200 | 401–801 | 150 | 0.15 | 1,800 | 75 | 1.2–1.8 |

| HUESKER Secutex® | 400 | 800–1,800 | 80 | 0.09 | 2,800 | 80 | 2.0–2.8 |

| Propex GeoTex® 601 | 200 | 534 | 200 | 0.18 | 1,500 | 78 | 1.0–1.6 |

| Low & Bonar Stabilenka® | 250 | 450 | 180 | 0.12 | 1,700 | 72 | 1.1–1.7 |

| Naue Secutex® | 300 | 500 | 100 | 0.10 | 2,200 | 80 | 1.3–2.2 |

| Maccaferri MacTex® | 350 | 600 | 90 | 0.09 | 2,500 | 78 | 1.6–2.3 |

| Berry Global Non-Woven | 180 | 360 | 220 | 0.20 | 1,400 | 72 | 0.9–1.5 |

| ADS N-Series 0601T | 160 | 400 | 250 | 0.20 | 1,200 | 70 | 0.8–1.4 |

| Colbond CX Non-Woven | 200 | 450 | 160 | 0.16 | 1,600 | 75 | 1.4–2.0 |

This matrix spotlights GEOSINCERE’s flux leadership and Propex’s frugality, aiding TCO for $0.6–2.8/m² spans.

4. What to Look for in the Best Non Woven Geotextile Drainage Fabrics

Procuring non-woven geotextile drainage fabrics mandates discerning scrutiny of attributes synced with GRI-GT13 and locale exigencies. Virgin polypropylene (≥97% purity) safeguards wholeness, averting 10–20% degradation from admixtures. Weights 100–800 g/m² calibrate to encumbrances, denser bestowing 25% puncture boons.

4.1 Non Woven Geotextile Drainage Fabrics – Permeability and Hydraulic Performance

Quintessential, transmissivity 0.05–0.4 cm/s (ASTM D4491) and AOS 0.05–0.2 mm (ASTM D4751) assure 95% retention sans impasse. Favor >100 L/m²/s for expeditious efflux in underdrains.

4.2 Non Woven Geotextile Drainage Fabrics – Mechanical Integrity and Load-Bearing

Grab tensile 400–2,500 N and elongations 25–200% (ASTM D4632) underpin rigors, 1.0–4.0 kN CBR and 100–300 N tears (ASTM D6241/D4533) mastering irregularities. Nonwovens procure 98% overlap potency.

4.3 Non Woven Geotextile Drainage Fabrics – Chemical and Environmental Resistance

pH 2–13 tolerance (ASTM D543) for leachates, with carbon black (2–3%) fortifying UV for 70–80% retention. AASHTO M288 Class 1 for biotic/chemical defiance.

4.4 Non Woven Geotextile Drainage Fabrics – Installation and Deployment Protocols

Broad rolls (4–6 m) and pinning yield 95% anchorage (ASTM D4885). Prefabs pare time 20%, with edge codices for audits.

4.5 Non Woven Geotextile Drainage Fabrics – Sustainability and Lifecycle Metrics

Recyclables (10–50%) and ISO 14001 for 10–15% footprint pares. 50-year interred tenures, with GRI calculators for ROI.

4.6 Non Woven Geotextile Drainage Fabrics – Cost-Benefit Projections

$0.5–3.0/m² upfront, $0.40/m² annual thrift over 50 years. Bulk (15–25%) for >5,000 m².

5. FAQs

5.1 What is the ideal permeability for non-woven geotextile drainage fabrics?

Permeability ≥0.05 cm/s (ASTM D4491) ensures 95% water throughput sans fines loss, paramount for underdrains; heavier grades (400+ g/m²) suit low-flux environs.

5.2 How do non-woven fabrics differ from woven in drainage applications?

Non-wovens excel in filtration (95% retention) and pliancy for uneven terrains, whilst wovens prioritize tensile (>20 kN/m) for stabilization; hybrids meld both for composites.

5.3 Are these fabrics suitable for exposed applications?

Yes, with 70–80% UV retention (ASTM D4355), they endure 5–10 years exposed; buried, 50+ years. Opt Class 1 AASHTO for harsh exposures.

6. Final Thoughts

Non-woven geotextile drainage fabrics are cornerstones of 2025’s resilient infrastructure, proffering data-validated efflux like 250 L/m²/s and 95% filtration for 50-year spans. From GEOSINCERE’s isotropic Continuous Filament to TenCate’s voluminous Mirafi® 180N, our ten eclipse GRI-GT13, with GEOSINCERE as editor’s choice for 35% flux and customization.

Fortify your schemas: Vet metrics, affirm conformance, ally judiciously. For GEOSINCERE bespoke, visit GEOSINCERE. Efflux excellence awaits.

Get Instant Quote

Ready to specify superior non-woven geotextiles? Submit project details—scale, application, specs—for a customized quote from GEOSINCERE. Examples: 200 g/m² for French drains, 400 g/m² for revetments. Email sales@geosyntheticscn.com or visit GEOSINCERE Geosynthetics —we respond within 24 hours for OEM/ODM needs.