In the field of modern civil engineering, mining, aquaculture, waste management, and environmental protection, geomembranes have become essential for waterproofing and anti-seepage applications. Among the various types of geomembranes, LLDPE geomembrane (Linear Low-Density Polyethylene) stands out due to its excellent flexibility, elongation, and chemical resistance.

As a professional geomembrane manufacturer and exporter, GEOSINO Geosynthetics provides a complete range of geomembrane solutions — from LLDPE, HDPE Geomembrane, PVC to textured geomembranes — for global customers in infrastructure, mining, and environmental projects.

This article will give you a comprehensive understanding of LLDPE geomembrane — what it is, how it’s made, its advantages, applications, installation tips, and how to select the right type for your project.

1. What Is LLDPE Geomembrane?

LLDPE geomembrane stands for Linear Low-Density Polyethylene geomembrane, a flexible synthetic liner made from virgin LLDPE resin with added antioxidants, carbon black, stabilizers, and anti-aging agents. It serves as a barrier against liquids, gases, and pollutants.

Compared with HDPE geomembrane, which is stiffer and stronger, LLDPE geomembrane offers greater flexibility and higher elongation, making it suitable for projects that require installation over uneven or irregular surfaces.

Key Physical Properties

| Property | LLDPE Geomembrane |

| Density | 0.915 – 0.935 g/cm³ |

| Tensile Strength | Medium |

| Elongation at Break | 700–1000% |

| Flexibility | Excellent |

| Chemical Resistance | High |

| UV Resistance | Excellent (with carbon black) |

In simple terms, LLDPE geomembrane is a soft, durable, and adaptable liner used to prevent liquid leakage, protect groundwater, and contain waste or chemicals.

2. The Production Process of LLDPE Geomembrane

GEOSINO’s LLDPE geomembrane is manufactured using advanced co-extrusion blown film or flat die extrusion technology. The process ensures uniform thickness, superior tensile properties, and long-term durability.LLDPE Geomembrane – Main Steps:

2.1 LLDPE Geomembrane – Raw Material Selection:

To ensure stable performance, we primarily select virgin LLDPE resin from leading global suppliers, such as ExxonMobil, Sinopec, or Dow Chemical. This careful selection is crucial because, ultimately, consistent material quality forms the foundation of our product reliability. Furthermore, by sourcing from these established producers, we can effectively maintain tight control over our manufacturing process. As a result, the final products consistently achieve the desired mechanical properties and quality standards.

2.2 LLDPE Geomembrane – Formulation:

During the compounding process, we actively integrate carbon black, antioxidants, and stabilizers. As a result, this critical step substantially boosts the product’s overall stability, including its resistance to UV light, aging, and various chemicals.

2.3 LLDPE Geomembrane – Extrusion:

First, we melt and then extrude the resin mixture through a die to form a thin sheet. Depending on the specific application, this versatile extrusion process can subsequently produce either single-layer or multi-layer geomembranes.

2.4 LLDPE Geomembrane – Cooling and Shaping:

We then direct the molten film through cooling rollers. This process simultaneously stabilizes the internal structure and calibrates the dimensions, which is essential for achieving uniform material properties.

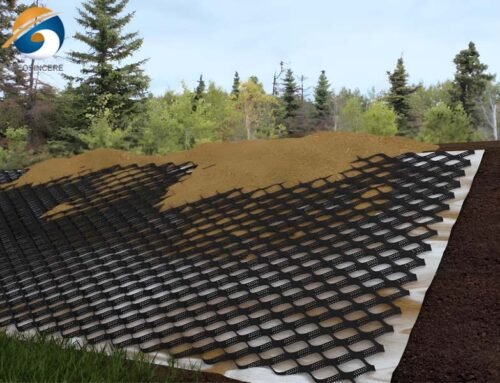

2.5 LLDPE Geomembrane – Surface Treatment (Optional):

For applications requiring superior friction, we specifically produce a textured surface. This process thereby directly enhances the geomembrane’s grip and overall slope stability.

2.6 LLDPE Geomembrane – Inspection and Packaging:

Every roll is tested for thickness, tensile strength, and appearance before being packed and labeled.

GEOSINO’s production line follows ISO9001 and GRI GM13 standards, ensuring consistent quality across all geomembrane products.

3. LLDPE Geomembrane vs. HDPE Geomembrane: What’s the Difference?

Both LLDPE and HDPE geomembranes are polyethylene liners, but their molecular structures and mechanical behaviors differ.

| Feature | LLDPE Geomembrane | HDPE Geomembrane |

| Flexibility | High | Low |

| Tensile Strength | Moderate | High |

| Elongation | 700–1000% | 300–500% |

| Puncture Resistance | Excellent | Very good |

| Chemical Resistance | High | Very high |

| Cost | Slightly higher | Slightly lower |

| Application Surface | Uneven, complex | Flat, stable |

In summary:

- LLDPE is better for irregular or unstable surfaces.

- HDPE is better for large, flat installations like landfills and reservoirs.

- Many engineers use LLDPE for secondary containment or where flexibility and stress cracking resistance are priorities.

4. Key Advantages of LLDPE Geomembrane

Choosing LLDPE geomembrane provides several technical and economic benefits:

4.1 LLDPE Geomembrane – Excellent Flexibility

LLDPE geomembrane conforms naturally to ground contours due to its outstanding flexibility. Furthermore, this inherent flexibility allows it to effectively accommodate future settlement or ground movement without cracking.

4.2 LLDPE Geomembrane – High Elongation Rate

Owing to its exceptional elongation of over 700%, the LLDPE geomembrane can effectively withstand significant ground deformation. At the same time, its inherent flexibility allows it to conform seamlessly to uneven contours and accommodate subsequent settlement or movement without cracking. This combination of properties ultimately makes it an ideal and reliable solution for challenging projects in seismic or otherwise unstable areas.

4.3 LLDPE Geomembrane – Strong Puncture and Tear Resistance

The unique molecular structure of LLDPE provides it with superior tear resistance compared to HDPE. Consequently, this enhanced durability significantly reduces the risk of installation damage, particularly during critical stages like backfilling, thereby ensuring long-term liner integrity.

4.4 LLDPE Geomembrane – Superior Chemical Resistance

Thanks to its robust chemical resistance, LLDPE geomembrane effectively withstands a wide range of substances, including acids, alkalis, salts, and hydrocarbons. As a result, it reliably ensures long-term stability in demanding applications, making it a trusted choice for critical chemical containment and industrial waste storage projects.

4.5 LLDPE Geomembrane – Excellent UV and Weather Resistance

By stabilizing our LLDPE geomembrane with carbon black, we equip it to withstand prolonged sunlight exposure for over 15 years. This deliberate formulation therefore makes it a highly suitable and durable solution for long-term, open-air installations.

4.6 LLDPE Geomembrane – Easy Installation

The inherent softness and excellent weldability of LLDPE geomembrane make hot wedge welding or extrusion welding notably easier to execute. This advantageous material property remains particularly effective under challenging low-temperature conditions, thereby facilitating reliable and efficient seam installation in colder climates.

4.7 LLDPE Geomembrane – Long Service Life

When properly installed, an LLDPE liner can reliably perform for over 30 years under normal environmental conditions. This exceptional service life, therefore, establishes it as a durable and cost-effective long-term containment solution.

5. Typical Applications of LLDPE Geomembrane

LLDPE geomembrane is used in a wide range of industries and environmental projects. Here are the main applications:

5.1 Landfill Liners and Covers

Used as a bottom liner and capping layer to prevent leachate leakage and gas migration.

5.2 Wastewater Treatment Ponds

Acts as an impermeable barrier in industrial wastewater lagoons, oxidation ponds, and sewage reservoirs.

5.3 Mining Industry

Applied in heap leach pads, tailing ponds, and process solution ponds to isolate chemicals and prevent groundwater pollution.

5.4 Aquaculture (Fish and Shrimp Ponds)

Provides a clean and non-toxic waterproof base, reducing water seepage and improving pond hygiene.

5.5 Agriculture and Irrigation

Used in canals, reservoirs, and water storage tanks to reduce water loss and soil erosion.

5.6 Secondary Containment

Provides reliable protection for chemical storage tanks and fuel containment systems.

5.7 Tunnel and Dam Projects

Acts as a seepage control barrier for tunnels, dams, and retaining structures.

5.8 Environmental Remediation

Used in hazardous waste sites or contaminated soil remediation to isolate pollutants.

6. Installation and Welding Methods

Proper installation is critical to ensure geomembrane performance. GEOSINO provides professional installation guidance and on-site technical support to clients worldwide.

6.1 Main Welding Techniques:

Hot Wedge Welding:

Common for seam joining; provides a smooth, watertight connection.

Extrusion Welding:

Used for corners, T-joints, and repairs.

Dual Track Welding:

Creates double seams with a central channel for air pressure testing.

6.2 Installation Precautions:

Ensure the base surface is smooth and free from sharp objects.

Overlap adjacent sheets by 10–15 cm.

Avoid installation during strong winds or rain.

Perform air pressure tests on all weld seams.

Protect geomembrane from mechanical damage during backfilling.

GEOSINO’s installation team has completed numerous overseas projects — from landfills in Southeast Asia to aquaculture ponds in Africa — ensuring reliable and durable performance.

7. Quality Standards and Testing

GEOSINO’s LLDPE geomembrane complies with the following international standards:

- GRI GM17 (LLDPE Geomembrane Standard)

- ASTM D5199 (Thickness)

- ASTM D638 (Tensile Strength and Elongation)

- ASTM D1004 (Tear Resistance)

- ISO 9001:2015 Quality System

Before shipment, each batch undergoes strict laboratory testing for mechanical and hydraulic performance.

8. Factors Affecting LLDPE Geomembrane Price

The price of LLDPE geomembrane varies depending on several factors:

- Thickness – Thicker membranes use more material, increasing the cost.

- Raw Material – Virgin resin costs more but ensures longer life.

- Surface Type – Textured surfaces cost slightly more.

- Additives – UV-stabilized or special formulations affect price.

- Order Quantity – Larger orders reduce cost per square meter.

- Transportation – Depends on distance and packaging method.

At GEOSINO, we always offer factory-direct prices and support custom production, helping clients balance cost and performance effectively.

9. How to Choose the Right LLDPE Geomembrane

When selecting LLDPE geomembrane for your project, consider the following:

- Project Type

- Chemical Environment

- Temperature and UV Exposure

- Ground Conditions

- Installation Environment

GEOSINO’s technical team can recommend the best geomembrane specification according to your design drawings or project requirements.

10. Why Choose GEOSINO as Your Geomembrane Supplier?

As a professional manufacturer and exporter of geosynthetic materials, GEOSINO Geosynthetics has built a solid reputation in over 50 countries.

Our Strengths:

- Professional Production

- Strict Quality Control

- Global Export Experience

- Technical Support

- Customized Solutions

- Competitive Pricing

GEOSINO’s goal is to provide not just products, but integrated geomembrane solutions to help customers succeed in their projects.

11. Sustainability and Environmental Benefits

LLDPE geomembrane not only protects water and soil but also supports sustainable engineering:

- Leak Prevention

- Waste Reduction

- Recyclable Material

- Energy Efficient Production

At GEOSINO, sustainability is integrated into every stage — from raw material selection to logistics.

12. Conclusion

LLDPE geomembrane is one of the most reliable and versatile materials for waterproofing and environmental containment. Its superior flexibility, elongation, and weldability make it ideal for modern engineering projects.Choosing GEOSINCERE Geosynthetics means choosing quality, expertise, and long-term reliability.If you are searching for a trusted LLDPE geomembrane supplier, GEOSINCERE is your best partner.