Geomembrane liner, when we have many options,will hard to choose.

In Thailand, geomembrane liners find extensive usage in projects such as landfill liners, reservoirs, ponds, canals, irrigation systems, geomembrane covers, secondary containment systems, and other containment structures. The specific type of geomembrane liner used depends on factors like the project requirements, environmental conditions, regulations, and budget.

As the leading geosynthetics manufacturer and supplier, GEOSINCERE offer various types HDPE liner with custom thickness and size at best factory price.

1. What Is Geomembrane Liner In Thailand?

Geomembrane liners are designed to provide impermeability and prevent the migration of liquids, gases, or contaminants in a wide range of applications. They are commonly used in industries such as agriculture, construction, mining, waste management, water and wastewater treatment, and environmental protection.

The geomembrane liners in Thailand are available from various suppliers and manufacturers who offer different grades, thicknesses, and sizes to cater to diverse project needs. It is important to select a suitable geomembrane liner that meets the specific requirements of the project, offers durability, chemical resistance, and complies with relevant industry standards and regulations.

2. What Are Benefits of Geomembrane Liner?

Geomembrane liners offer several benefits in various applications. Here are some key advantages of using geomembrane liners:

2.1 Water Quality Protection

Geomembrane liners effectively block contaminants from seeping into nearby water sources, ensuring cleaner aquatic ecosystems. These specialized barriers actively prevent harmful substances from mixing with surrounding water bodies, maintaining optimal water purity. By creating a secure containment system, the liners directly support healthier living conditions for fish and other marine life. Furthermore, this protective function allows for better environmental control, enabling aquatic organisms to thrive in balanced, pollution-free habitats.

2.2 Disease Prevention

Geomembrane liners simplify pond maintenance by providing smooth, non-porous surfaces that allow for thorough cleaning. Their impermeable nature enables more effective disinfection procedures that eliminate pathogens between production cycles. These liners actively prevent cross-contamination between different pond sections, significantly lowering disease transmission risks. Moreover, the enhanced biosecurity measures directly contribute to healthier aquatic stocks and more stable production yields.

2.3 Containment of Waste

Geomembrane liners create an impermeable barrier that effectively blocks hazardous substances from escaping landfill sites. These specialized liners actively prevent toxic materials from seeping into adjacent soil layers, maintaining soil integrity. By stopping contaminant migration, they directly protect groundwater resources from pollution and degradation. Furthermore, this containment system significantly reduces potential environmental hazards while ensuring long-term ecological protection.

2.4 Landfill Gas Management

Geomembrane liners work synergistically with gas collection systems to effectively trap and control landfill gas emissions. These integrated systems actively capture methane and other gases before they can escape into the atmosphere. By containing these emissions, the technology directly reduces harmful greenhouse gas outputs that contribute to climate change. Additionally, this solution minimizes potential health hazards for nearby communities while converting waste gases into usable energy resources.

2.5 Longevity and Durability

Geomembrane liners demonstrate exceptional resistance to environmental stressors, maintaining their structural integrity for decades. Their robust material composition actively withstands chemical exposure, punctures, and UV degradation throughout the landfill’s operational life. This extended durability directly translates to fewer liner failures and significantly lower maintenance requirements. Moreover, the reduced need for repairs or replacements leads to substantial long-term cost savings for landfill operators.

2.6 Acid and Chemical Resistance

Geomembrane liners effectively withstand exposure to harsh acids and aggressive chemicals found in mining environments. These engineered materials actively maintain their structural integrity even when contacting corrosive substances from mining processes. Their superior chemical resistance directly prevents leaks and breaches in containment systems. Furthermore, this reliable performance consistently safeguards surrounding ecosystems from potential mining-related contamination.

2.7 Erosion Control

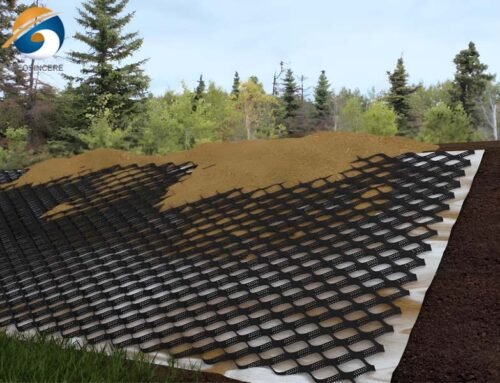

Geomembrane liners actively reinforce slope stability by creating a protective barrier that anchors mining waste materials in place. Their durable surface effectively dissipates erosive forces from wind and water, preventing surface degradation. This stabilization directly minimizes sediment runoff that could otherwise pollute nearby water sources. Moreover, the liners’ erosion control capabilities substantially reduce the mining operation’s overall environmental footprint while maintaining soil integrity.

3. What Are Types of Geomembrane Liner?

There are several types of geomembrane liners available, each with its own characteristics and applications. Here are some common types of geomembrane liners:

3.1 High-Density Polyethylene (HDPE) Geomembrane

- HDPE geomembranes are widely used due to their excellent chemical resistance, durability, and flexibility.

- They are suitable for applications such as landfill liners, reservoirs, ponds, and wastewater treatment plants.

3.2 Low-Density Polyethylene (LDPE) Geomembrane

- LDPE geomembranes are flexible and commonly used in applications with low stress, such as decorative ponds or small-scale containment projects.

3.3 Polyvinyl Chloride (PVC) Geomembrane

- PVC geomembranes are known for their chemical resistance and UV stability.

- They are commonly used in applications such as decorative ponds, agricultural ponds, and secondary containment.

3.4 Ethylene Propylene Diene Monomer (EPDM) Geomembrane

- They are suitable for applications that require high flexibility and conformability, such as decorative ponds, water features, and rooftop gardens.

3.5 Reinforced Polyethylene (RPE) Geomembrane

- RPE geomembranes combine HDPE with reinforcing scrim for enhanced strength and tear resistance.

- They are commonly used in applications such as pond liners, floating covers, and secondary containment.

3.6 Polypropylene (PP) Geomembrane

- PP geomembranes have good chemical resistance and are often used in applications such as landfill caps, secondary containment, and agricultural ponds.

4. Ultimate Guide To Choose Best Geomembrane Liner in Thailand

Choosing the best geomembrane liner in Thailand requires careful consideration of various factors. Here is an ultimate guide to help you make an informed decision:

4.1 Project Requirements

Please provide specific details about your project requirements, including the application type (e.g., landfill, pond, mining), desired lifespan, environmental factors, and regulatory compliance.

4.2 Material Selection

Evaluate the different geomembrane materials available (e.g., HDPE, LDPE, PVC, EPDM) and consider their properties, including chemical resistance, flexibility, UV stability, and durability.

4.3 Thickness

Determine the appropriate thickness of the geomembrane liner based on factors such as anticipated stress levels, soil conditions, and the type of containment. Thicker liners offer increased puncture resistance and longevity.

4.4 Strength and Tear Resistance

Consider the strength and tear resistance requirements of your project. Reinforced options like RPE geomembranes provide enhanced strength and tear resistance, making them suitable for demanding applications.

4.5 Chemical Compatibility

Assess the chemicals and substances that the geomembrane liner will come into contact with. Choose a liner with excellent chemical resistance to ensure long-term integrity and prevent degradation.

4.6 Installation Considerations

Assess the installation prerequisites, which encompass site preparation, subgrade condition, and installation techniques. Certain geomembranes may necessitate specialized methods for installation, whereas others provide simplicity and adaptability during the installation process.

4.7 Manufacturer Reputation and Quality

Research the reputation and track record of the geomembrane manufacturer or supplier. Look for certifications and industry standards compliance to ensure the product’s quality and reliability.

4.8 Cost-Effectiveness

Compare the cost of different geomembrane options, considering factors such as initial installation costs, maintenance requirements, and expected lifespan. Strive for a balance between quality and cost-effectiveness.

4.9 Expert Advice

Seek advice from experienced professionals, engineers, or consultants who specialize in geomembrane liners. They can provide valuable insights and help you select the best liner for your specific project.

5. Summary

Selecting the best geomembrane liner in Thailand involves considering project requirements, such as application type and lifespan, while evaluating material properties like chemical resistance and durability. It’s essential to assess installation considerations, environmental factors, and seek expert advice to ensure a cost-effective choice that meets regulatory standards and delivers long-term performance.

GEOSINCERE brand geomembrane liner solutions can meet your requirements through our strong technology, innovative engineering solutions and excellent customer service.

Any questions or inquiries, please contact us.