Composite and textured geomembrane are two important categories of geomembranes playing important roles in the world of construction and environmental projects. Composite geomembranes are made from a combination of materials and are characterized by impermeability and high tensile strength; textured geomembranes have a textured surface structure that increases friction and skid resistance, and better binds to the soil to prevent erosion. Both are widely used in the fields of construction engineering, environmental engineering and geological engineering, and play an important role in ensuring the safety and efficiency of the project. What is the difference between composite and textured geomembrane? How to choose between composite geomembrane and textured geomembrane for specific projects?

GEOSINCERE is the leading geosynthetics and geomembrane manufacturer and supplier, We wholesale high quality geomembrane with complete sizes and thickness at great price. In this article, let’s better explain and master these two important engineering materials from the geomembrane manufacturer’s view, so as to provide strong theoretical support for practical engineering applications.

1 What Is Textured Geomembrane?

1.1 Surface Characteristics

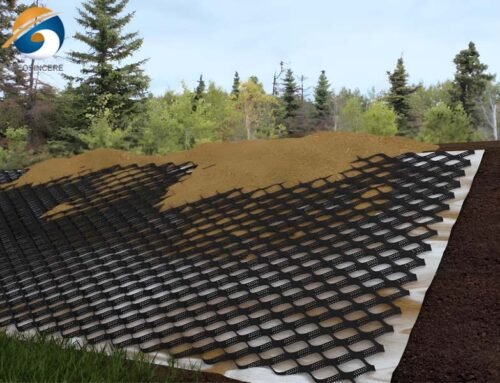

The surface design of GEOSINCERE textured geomembranes increases friction and shear resistance, giving them a unique advantage. These textures, such as studs, knobs or patterns, prevent the geomembrane from sliding or shifting and increase its ability to resist the effects of external forces. The design can be adjusted to meet the specific needs of different projects. This type of structure supports water conservation projects, soil reinforcement and environmental protection projects.

1.2 Key Characteristics

Increased Friction. The surface texture of textured geomemes enhances the friction force, prevents the material from sliding or displacing under dynamic conditions, meets the stability needs of the project, improves the friction force between other materials, and ensures the stability and safety of the project.

Shear Resistance. The texture structure of textured geomembrane can improve the shear resistance of the material and better resist external forces, especially in applications such as landfill lining to prevent the material from sliding or displacing, withstand pressure and shear forces.

2 What is Composite Geomembrane

Composite geomembranes are engineered, multi-layer materials. Essentially, they combine a geomembrane with a geotextile. Structurally, they resemble a sandwich for enhanced performance.

Notably, they provide strong, impermeable protection. Additionally, they improve soil stability effectively. Moreover, they support plant growth in environmental projects.

Due to these advantages, they are widely used. For instance, they work well in water conservancy. Similarly, they benefit soil stabilization efforts. Furthermore, they excel in environmental engineering.

2.1 Ultra durability

Composite geomembranes are designed with multiple layers that provide excellent puncture resistance, ensuring their durability. The material is able to withstand physical pressure and chemical corrosion from the outside, ensuring its stability during use.

2.2 Enhanced Strength

Composite geomembranes offer exceptional tensile strength, making them highly durable. As a result, they reliably support structural integrity in demanding conditions.

In engineering projects, they provide critical reinforcement. For example, they strengthen embankments and landfills effectively. Moreover, their stability enhances long-term safety.

Additionally, these geomembranes resist stretching and tearing. Consequently, they maintain performance under heavy loads. Therefore, they are ideal for high-stress applications.

Ultimately, their strength ensures project reliability. Thus, engineers widely trust them for vital infrastructure. In summary, they deliver both safety and longevity.

2.3 Stability

Composite geomembranes offer stable performance in various engineering projects. They ensure consistency in both large-scale containment and environmental projects. These geomembranes prevent pollutant infiltration and spread effectively. They isolate and protect the environment from chemical leaks. In eco-projects, they improve soil structure and promote plant growth. GEOSINCERE geomembranes provide durability, strength, and stability. They are ideal for containment and environmental protection applications. Their reliability supports the successful completion of projects. These materials are essential for pollution control and ecological restoration. GEOSINCERE products deliver long-term performance in demanding conditions. They are widely trusted for large-scale engineering solutions. Their use ensures environmental safety and project success.

3. Common Application of Textured And Composite Geomembrane

Textured geomembranes significantly improve friction and stability in engineering projects. Specifically, they excel in landfill lining systems by preventing slippage.

Thanks to their rough surface design, they enhance grip. As a result, they effectively resist pressure and shear forces. Consequently, project stability and safety are greatly improved.

Moreover, these geomembranes help prevent environmental contamination. For instance, they minimize leakage risks in waste containment. Additionally, they reduce accident potential in slope applications.

Ultimately, textured geomembranes offer reliable performance. Therefore, they are widely trusted for critical containment projects. In summary, they ensure both environmental protection and structural security.

3.1 Performance of Textured And Composite Geomembrane

Composite geomembrane delivers exceptional puncture resistance and tensile strength. Consequently, it significantly enhances structural stability in civil engineering. Particularly, it’s widely applied in highway and bridge construction. Additionally, this material effectively combats soil erosion. Moreover, it provides dependable environmental protection solutions.

Conversely, textured geomembrane features a distinctive rough surface. Specifically, its texture boosts friction and shear resistance properties. As a result, it reliably prevents slippage during heavy loading. Therefore, it’s perfect for projects demanding enhanced grip. Furthermore, it maintains stability in challenging environments long-term.

Ultimately, both geomembrane types serve critical roles. Thus, they represent indispensable solutions for contemporary engineering challenges. In summary, each offers specialized benefits for different project requirements.

3.2 Cost Considerations of Textured And Composite Geomembrane

Composite geomembrane costs more due to dual-layer material and welding. Textured geomembrane is cheaper with single-layer material and simple embossing.

Composite geomembrane has higher processing costs for heat fusion. Textured geomembrane requires low-cost embossing only.

Choose based on project needs and budget. Composite offers higher strength and durability. Textured is more cost-effective for basic needs.

Evaluate requirements before selecting. Composite suits demanding applications. Textured works for friction-focused projects. Balance cost and performance wisely.

3.3 Application Considerations of of Textured And Composite Geomembrane

3.3.1 Textured geomembranes

- Engineering requirements: Improve drainage and skid resistance.

- Texturing: Selection of suitable drainage holes and anti-slip textures.

- Construction method: Ensure level laying and secure fixing.

3.3.2 Composite geomembrane

- Engineering needs: select the composite geomembrane that meets the engineering protection requirements.

- Environmental conditions: consider the climate, soil and other factors, choose the appropriate composite geomembrane.

- Construction method: Ensure proper laying and connection to improve the use effect.

In general, when selecting composite geomembranes and textured geomembranes, comprehensive consideration needs to be given to factors such as the specific needs of the project, environmental conditions and construction methods. Choosing suitable geomembrane materials and correct construction methods can ensure that their application effects are optimal and meet the needs of the project.

3.4 Environmental Impact of Textured And Composite Geomembrane

Composite geomembranes are harder to recycle due to their multi-layer structure. Separating layers requires specialized recycling methods.

Textured geomembranes have environmental benefits from their design. The textured surface improves friction and shear resistance. This enhances performance in engineering applications.

The texture also extends the material’s lifespan. Longer use means less frequent replacement. This reduces waste and benefits the environment.

Both types serve different ecological needs. Composite offers strength but recycling challenges. Textured provides sustainability through durability. Choose based on project priorities.

3 Real Case Studies of Textured And Composite Geomembrane

3.1 GEOSINCERE HDPE Textured Geomembrane for Mining Project in Peru

3.1.1 Main Issue of HDPE Textured Geomembrane for Mining Project in Peru

Mining is a serious threat to the environment and protective measures are needed. The Peruvian client wanted to prevent seepage from mining excavations by laying a protective geomembrane. The complex topography of the construction site added to the challenge.

3.1.2 Solution of HDPE Textured Geomembrane for Mining Project in Peru

Depending on the situation, GEOSINCERE’s professional engineers decided to use HDPE textured geomembranes as liners to protect the slope. GEOSINCERE HDPE textured geomembrane prevents rainwater from entering the soil and ensures stability. The application in complex broken open pit mine slopes prevents sliding and the presence of large amounts of rainwater causing cracking.

3.2 GEOSINCERE Composite Geomembrane Liner for Industrial Waste Treatment in Thailand

3.2.1 Main Issue of Composite Geomembrane Liner for Industrial Waste Treatment in Thailand

Industrial wastes threaten the environment, occupy land and may contaminate the soil. Harmful ingredients enter water bodies, endangering human health and destroying ecology. The wide variety of waste poses challenges to the environment. Improper handling can lead to contamination that affects crops and human health. But if handled correctly, it can be transformed into a valuable resource.

3.2.2 Solution of Main Issue of Composite Geomembrane Liner for Industrial Waste Treatment in Thailand

Based on the information provided by the customer in Thailand, the solution chosen by the GEOSINCERE engineers was to lay composite geomemofilm in the valley depression treatment site to prevent rainwater and sewage infiltration. Considering the possible collapse problem caused by soft soil backfilling, high tensile strength of the material is required. GEOSINCERE engineers finally selected a 4-meter-wide GEOSINCERE composite geomembrane, which was bonded on site to expand the area, with one end anchored at the top of the slope and a pile distance of 15-20 meters.

4 Conclusion

In conclusion, when choosing between composite and textured geomembranes, you need to consider project needs, performance characteristics, cost and environmental factors. Composite geomembranes offer excellent puncture resistance and tensile strength for projects subjected to high external forces, while textured geomembranes offer excellent friction and shear resistance.

For scenario applications that require a combination of geotextile and geomembrane, composite geomembranes have a higher product cost, but may still be an economically viable option due to their lower one-time combined installation cost. For application scenarios that do not require a geotextile, such as slopes, textured geomembranes are the preferred choice because of their lower product cost and relatively simple construction methods.

Any questions or inquires, please contact us.